Traction row wheel type container carrying system

A handling system and container technology, applied in the direction of lifting device, transportation and packaging, multi-axis trolley, etc., can solve the problems of low utilization rate of site area, low loading and unloading efficiency, complicated control, etc., so as to shorten the loading and unloading work time, reduce The effect of labor hours and safe handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

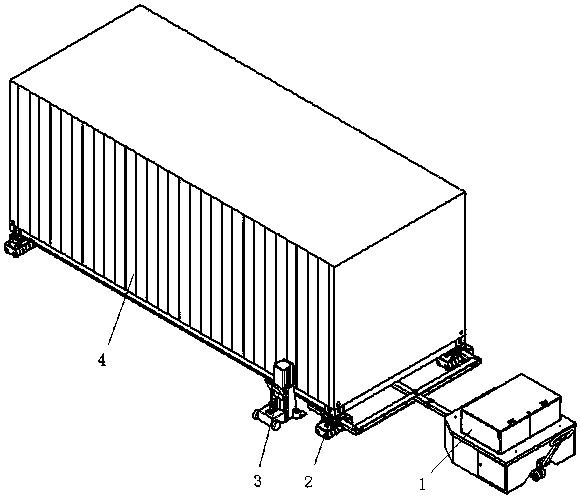

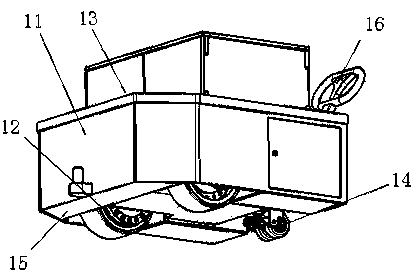

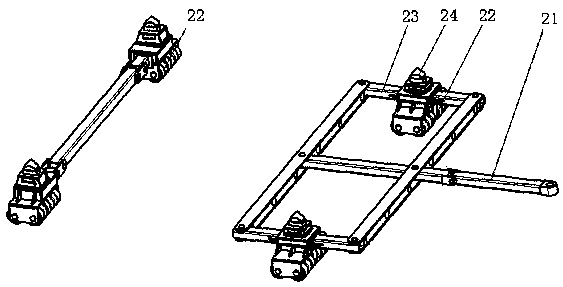

[0016] Such as Figure 1-4 As shown, the present invention is a traction wheeled container handling system, which includes a power cart 1, a small transport tank 2, and a hydraulic jack 3. The power cart 1 is used for traction and movement of the container 4, and includes a car body 11 , and the driving wheel set 12, battery 13, driven wheel 14, counterweight 15, electrical system 16 installed on the car body 11, the counterweight 15 is installed on both sides and tail end of the front section of the car body 11, increasing the power push The overall weight of the cart 1 enables the power cart 1 to generate a large enough traction friction force on the ground to ensure that the container 4 can be traction-driven to realize the movement of the container 4 such as moving forward, backward, and turning left and right. The small transport tank 2 includes Connecting rod 21, row wheel 22, rotary device 23, described connecting rod 21 is installed on the rotary device 23, and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com