Conveying positioning device used for conveying flexible strip-shaped objects

A positioning device and strip-shaped object technology, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of flexible strip-shaped objects offset, reduce production efficiency, waste of flexible strip-shaped objects, etc., to avoid deviation , improve production efficiency and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

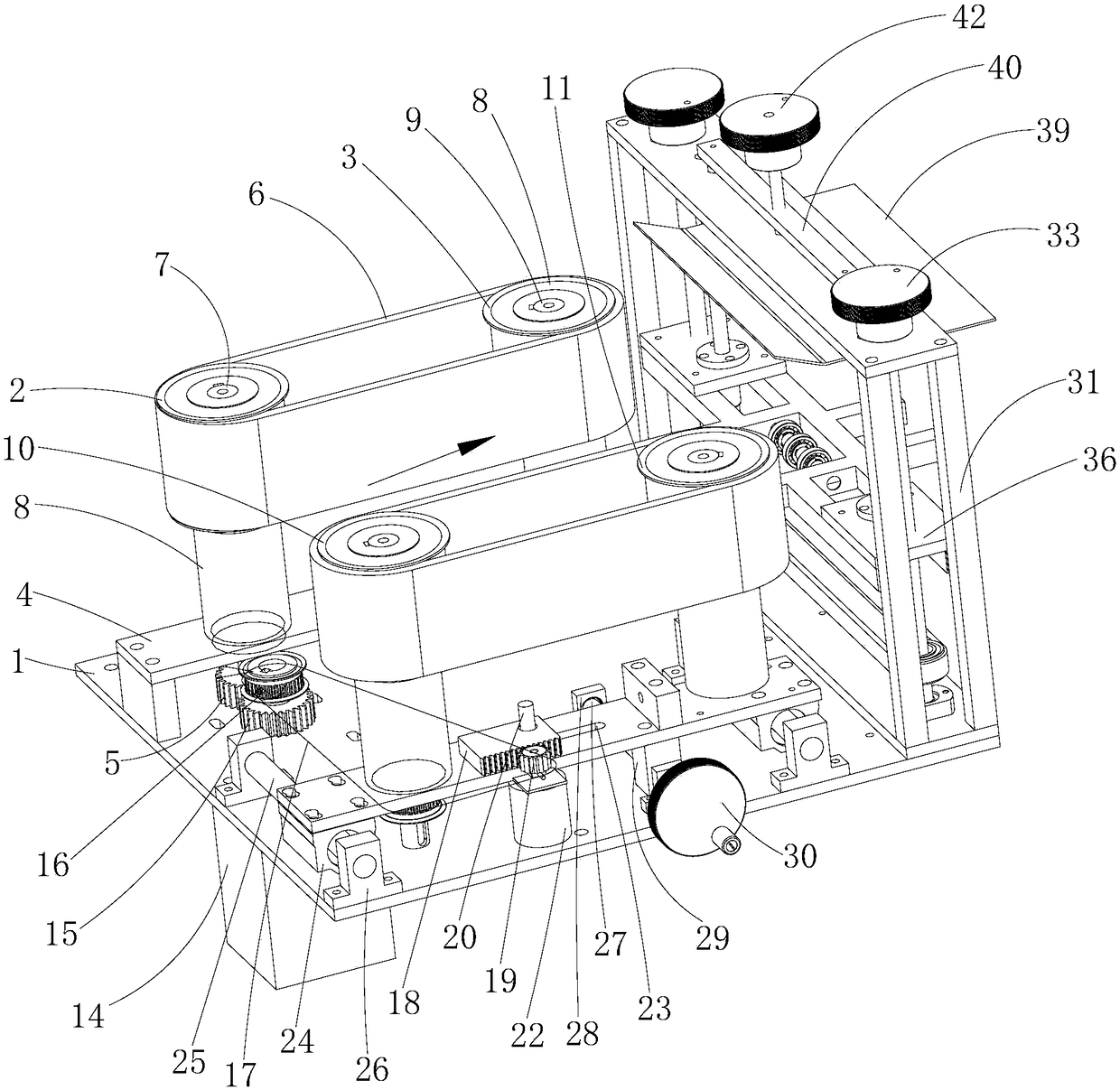

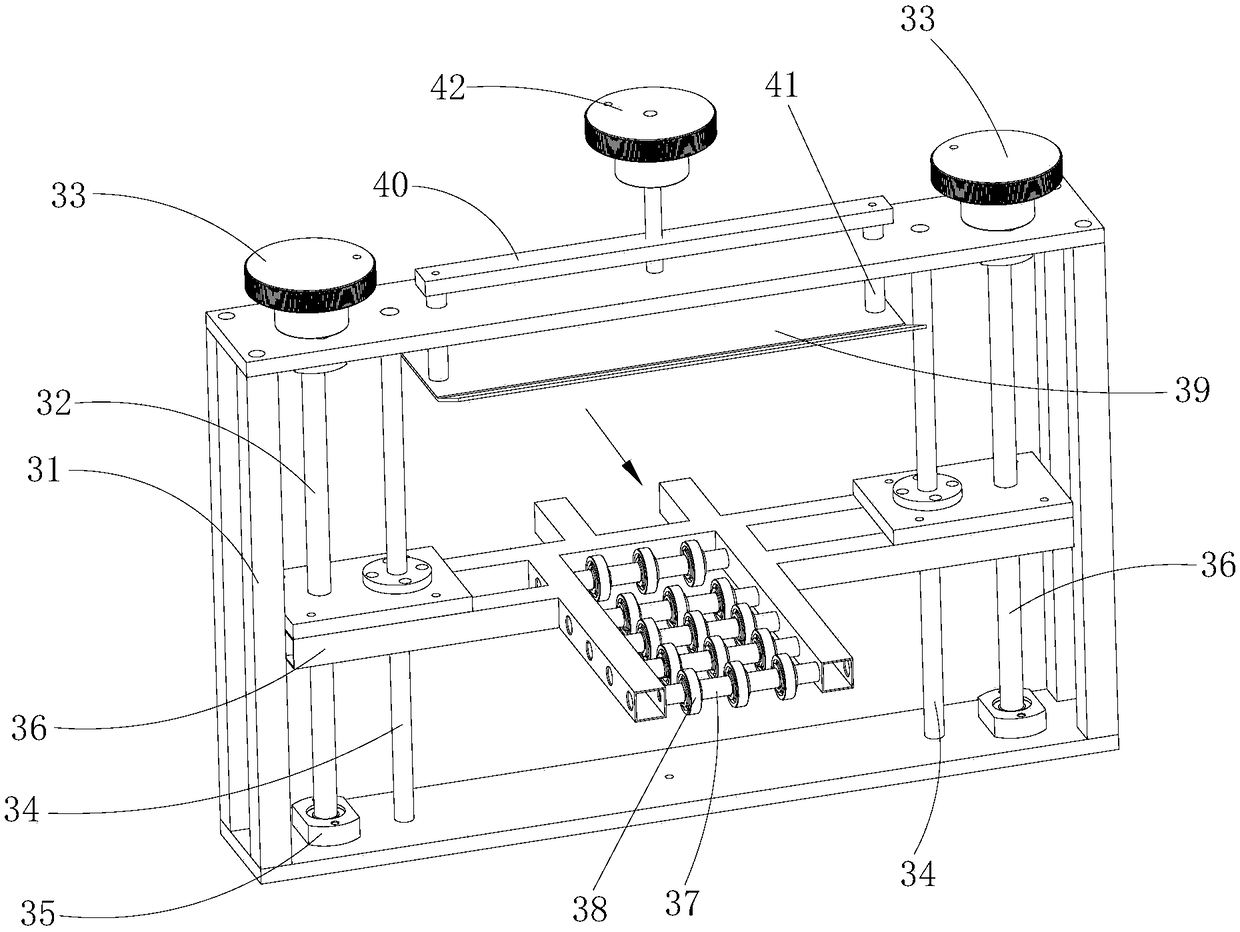

[0033] see figure 1 and figure 2 , a transmission positioning device, including a workbench 1, a first pulley set arranged on the workbench 1, a second pulley set movable relative to the first pulley set, a first working support 4 corresponding to the first pulley set, The second working support 13 corresponding to the second pulley set, the active driving device that makes the first pulley set and the second pulley set run at the same speed and in the opposite direction, adjust the first pulley set and the second pulley set according to the flexible strip object transmitted. A distance adjusting device for the distance between the pulley sets, and a guiding transmission device arranged opposite to the first pulley set and the second pulley set.

[0034] The first work support 4 is fixedly arranged on the workbench 1, and the second work support 13 is arranged on the workbench 1 movable relative to the first work support 4; Rotating first gear 15 and second gear 16 . In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com