Laser film cutting and laminating machine

A technology of laser cutting and laminating mechanism, applied in laser welding equipment, manufacturing tools, chemical instruments and methods, etc., can solve the problems of low cutting precision, low work efficiency, and easily damaged products, etc., to save film and improve processing. Efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

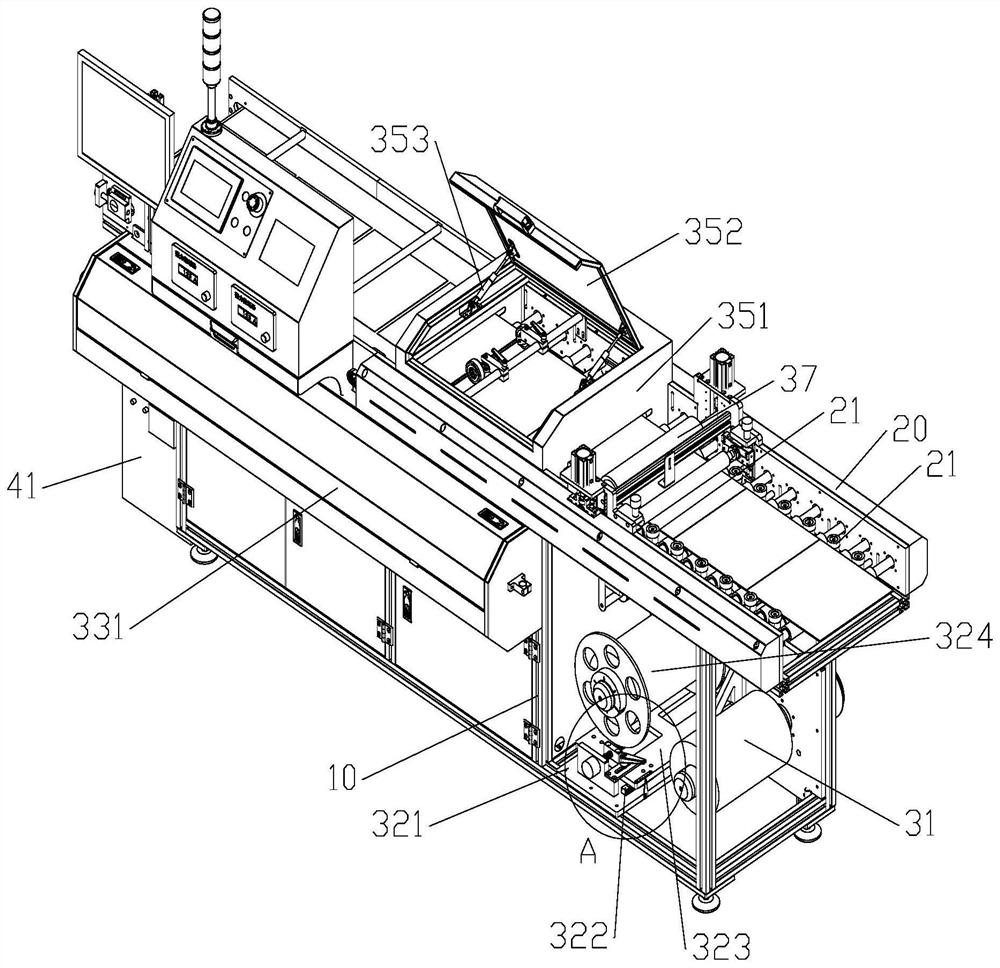

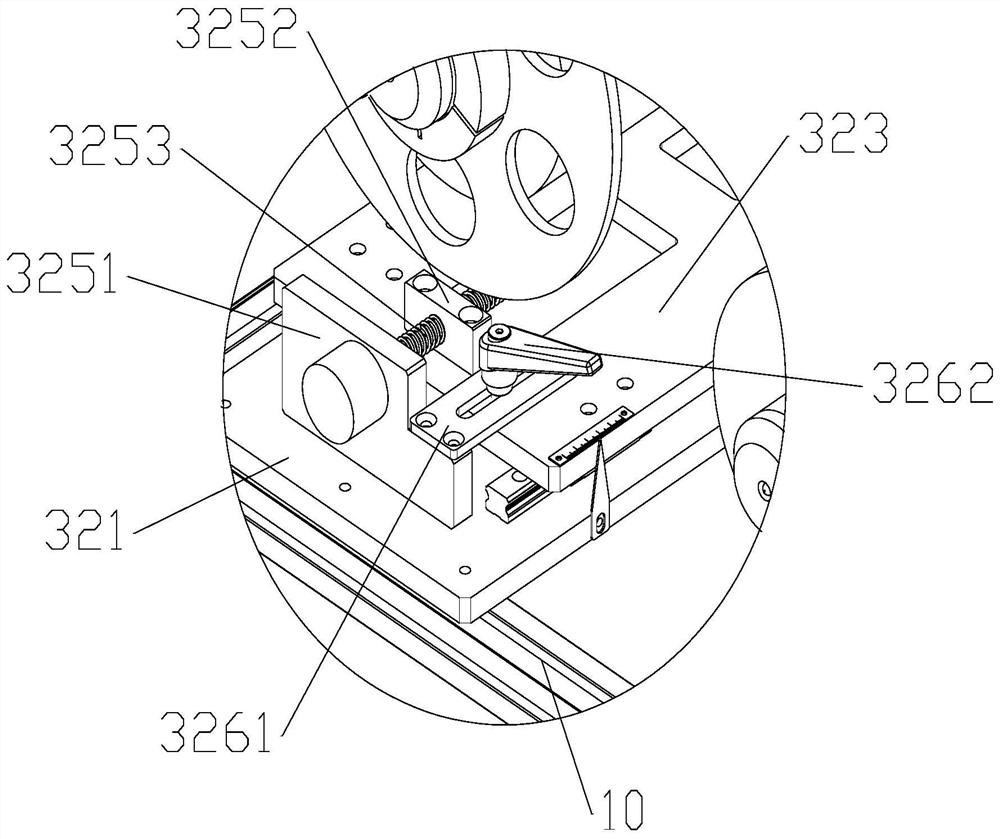

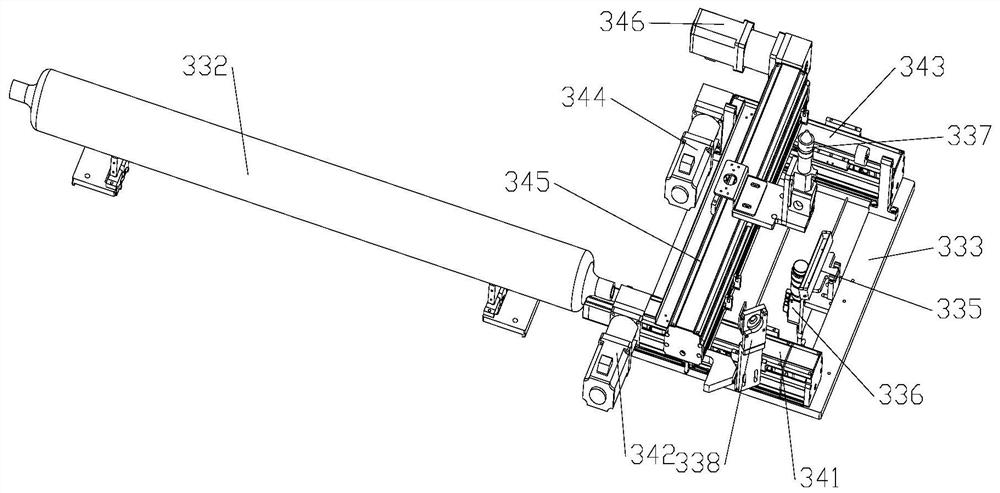

[0025] Such as Figure 1 to Figure 4 As shown, the laser cutting film laminating machine includes a frame 10, a conveying roller table 20 for linearly conveying the plate is arranged above the frame 10, a plate laminating mechanism and a laser film cutting mechanism are arranged in the frame 10, and the frame One side of the laser tube 10 is provided with a laser tube protective case 331; the conveying roller table 20 adopts a power roller, which can continuously transport the sheet material forward. Positioning rollers 21 are also installed between the entrance and the mold roller assembly; the plate coating mechanism includes a film roller device, a release paper collection roller 31 and a film roller assembly, and the release paper collection roller 31 is installed on the top of the film roller device. In the front, the laminating roller as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com