Lens module production equipment

A lens module and production equipment technology, applied in installation, optics, instruments, etc., can solve the problems of reduced splicing efficiency, increased equipment cost and maintenance cost, etc., to save equipment cost and maintenance cost, save equipment cost, and improve splicing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

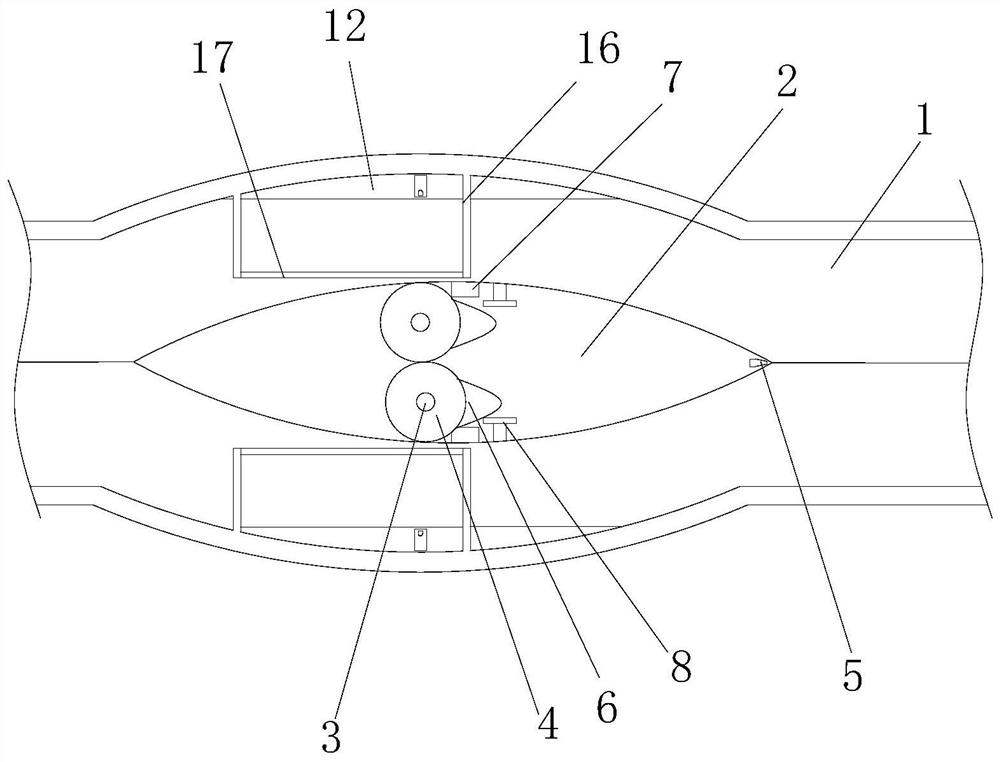

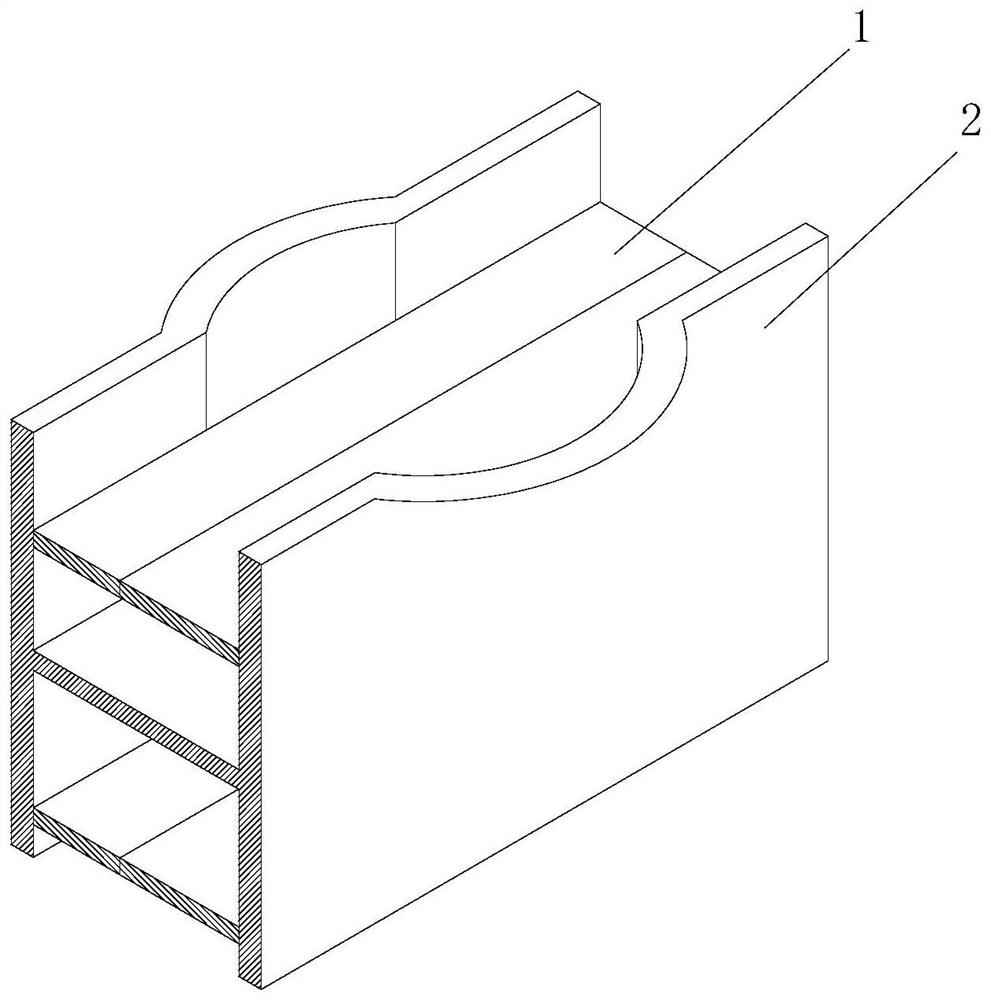

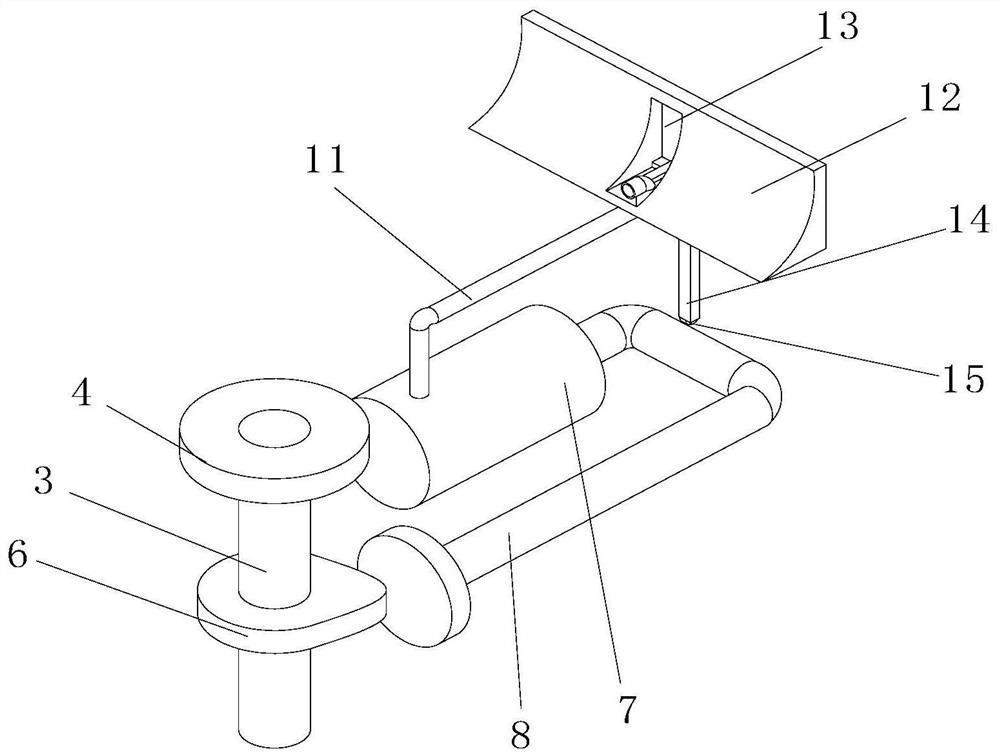

[0044] Example 1: Please refer to Figure 1-5 , the production equipment of the lens module, including the transmission belt 1 and the transmission table 2, the number of the transmission belt 1 is two and the front and back are in a corresponding state, the corresponding sides of the two transmission belts 1 are in a bonded state, and the two transmission belts 1 Both are connected with a transmission mechanism, the transmission belt 1 and the transmission mechanism are existing known technologies, the transmission belt 1 is made to rotate through the transmission mechanism, so as to transport the articles on the transmission belt 1, and will not repeat them here. The shape of the table 2 is rectangular and the top surface is provided with a rectangular groove. The transmission table 2 is located in the middle of the inner ring of the transmission belt 1. Two rotating bearings are fixedly installed in the center of the top surface of the transmission table 2. The inner ring of...

Embodiment 2

[0047] Example 2: Please refer to Figure 6-11 , on the basis of Embodiment 1, splicing plate A18 is placed on the conveyor belt 1, and the shape of splicing plate A18 is a T-shaped body. 19 is fan-shaped, and the two guide plates 19 are opposite. The sides of the two guide plates 19 away from the splicing plate A18 are respectively fixedly connected to the front and rear inner walls of the transfer table 2. The splicing plate A18 is located at the left end of the transfer table 2. , the top of the right side of the splicing plate A18 is fixedly connected with two lens barrels 20 respectively, the lens barrel 20 is a rectangular body hollowed out on the top surface, the top surface of the lens barrel 20 is hollowed out, and the left side inner wall of the lens barrel 20 is fixedly connected with Return spring B21, the unfixed end of return spring B21 is fixedly connected with push plate 22, and the inner wall of the top surface on the left side of lens barrel 20 is provided wi...

Embodiment 3

[0050] Example 3: Please refer to Figure 12-13 , on the basis of Embodiment 2, the front and rear inner walls of the transfer table 2 are fixedly connected with two splicing plates B34 on the right side of the splicing plate A18, and the gap between the diameters of the two splicing plates B34 is consistent with the thickness of the two frames connected. The corresponding side of A18 and splicing plate B34 is all provided with chute 35, and in the left and right corresponding chute 35, all is socketed with a slide plate 36, and the right end of slide plate 36 is magnet material and is opposite to the magnetic pole on the left side of strong magnet A28, two The corresponding side of the slide plate 36 is fixedly connected with a slider 37. Through the setting of the splicing plate B34, the frame for installing the lens is automatically spliced, which is conducive to further improving the production efficiency of the lens module, and does not require external power and sensing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com