Intelligent automatic winding equipment

A kind of equipment and automatic technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of poor winding position accuracy, the adjustment block cannot move up and down stably, and has no lighting function, etc., to achieve the winding position precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

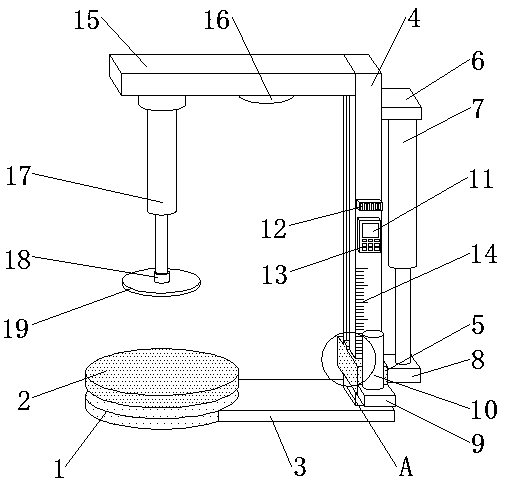

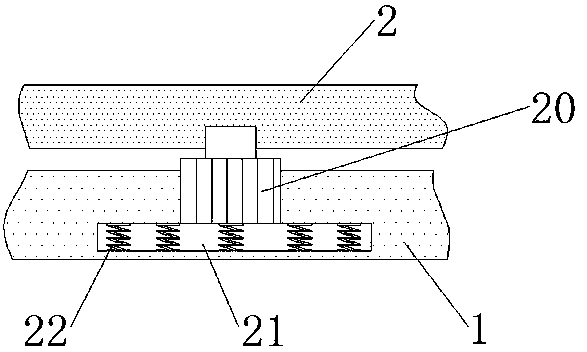

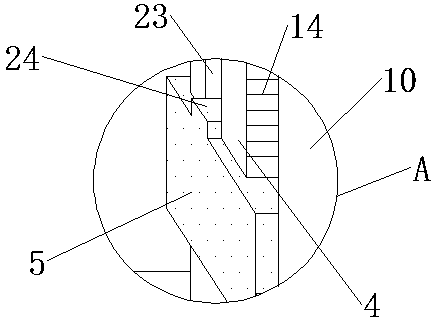

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution for intelligent automatic winding equipment, a kind of intelligent automatic winding equipment, including a base 1, a motor 20 is installed on the top of the base 1, a turntable 2 is connected to the top of the motor 20, and the inside of the base 1 The bottom end of the motor 20 is provided with a supporting block 21, the inside of the supporting block 21 is provided with a spring 22, one end of the base 1 is connected with a connecting plate 3, the top of the connecting plate 3 is connected with a connecting column 4, and the outer side of the connecting column 4 is connected with a Adjusting block 5, and the top of adjusting block 5 is provided with projection 24, and the inside of connecting column 4 is provided with limit groove 23 at the position corresponding to projection 24, and one side of connecting column 4 is connected with fixed plate 6, and the fixed plate 6 The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com