Design method of high-position unloading loading machine

A design method and loader technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of increased counterweight quality, decreased stability of the whole machine, and increased length of the whole machine, so as to facilitate production organization and management, The effect of maintaining flexibility and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

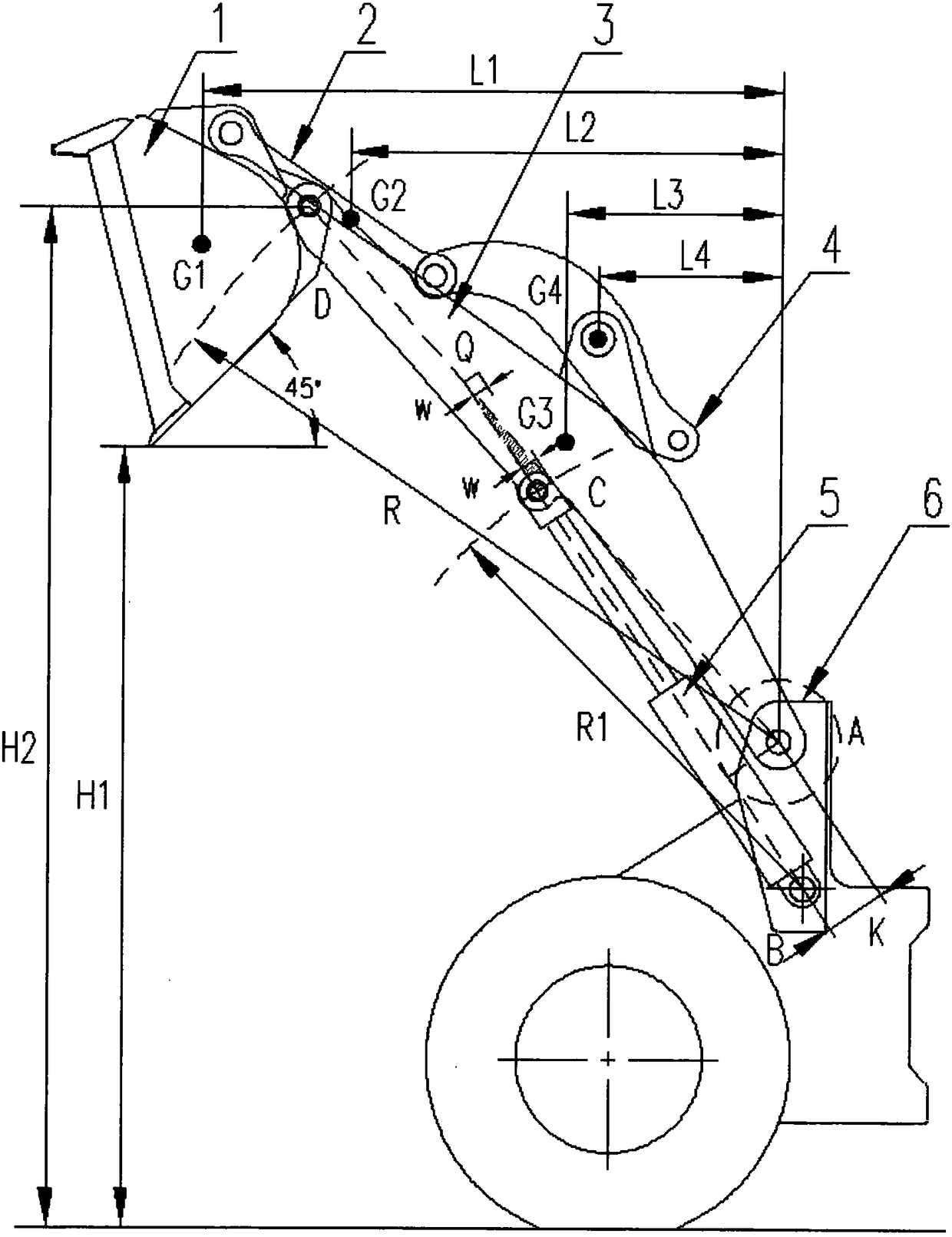

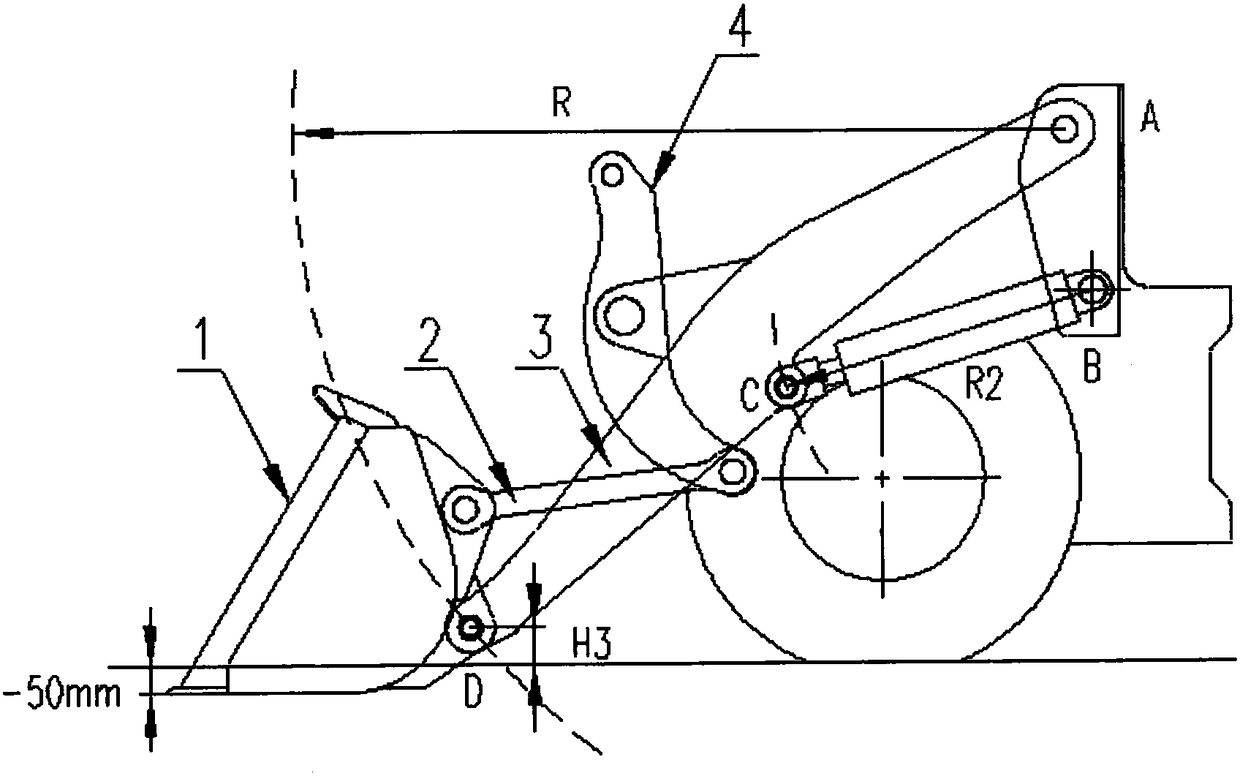

[0023] figure 1 , 2 They are the front view of the loader working device during high unloading and the front view of the loader working device when the bucket is digging, respectively. The design method of a high unloading loader provided in this embodiment includes the following steps:

[0024] Step 1): According to the unloading state of the bucket 1 when it is turned forward by 45°, determine the new high unloading height H1 of the whole machine, and calculate the vertical height H2 of the hinge point D between the boom 3 and the bucket 1;

[0025] Step 2): Take the hinge point A of the boom 3 and the front frame 6 as the circle point, take the hinge point D of the boom 3 and the bucket 1 as the end point, and the distance R between the two hinge points AD as the radius, clockwise Rotate the boom 3 to adjust the hinge point D of the boom 3 and the bucket 1 to a new vertical height H2;

[0026] Step 3): In this state, calculate Display all passive component moment values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com