Braking unit based on friction shifting

A technology for connecting brake discs and units, applied in the direction of brakes, brake types, mechanical equipment, etc. in the axial direction, which can solve the problem that medium brake pads are not as good as high-quality brake pads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

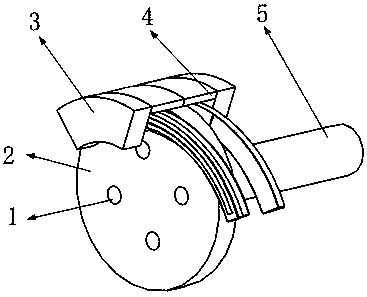

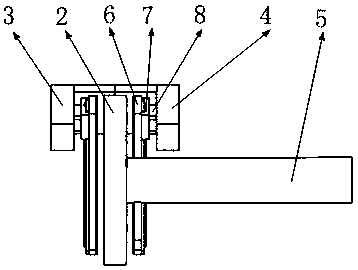

[0018] Such as figure 1 , 2 As shown, it includes a brake disc 2, a first brake unit 3, a second brake unit 4, and a rotating shaft 5, wherein the brake disc 2 is installed on one end of the rotating shaft 5, and the first brake unit 3 and the second brake unit 4 have the same structure and are symmetrical. It is installed on the chassis of the car, and the first brake unit 3 and the second brake unit 4 are located on both sides of the brake disc 2 .

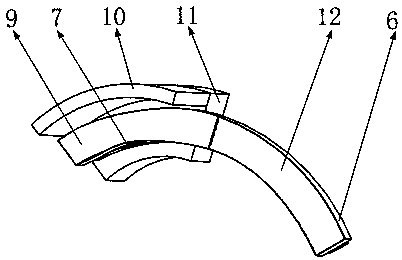

[0019] Such as image 3 As shown, the above-mentioned first brake unit 3 includes a fan-shaped brake support 6, a power plate 7, a hydraulic column 8, a brake unit connecting shell 10, a brake unit hydraulic shell 11, a guide rail groove 13, a sleeve rod groove 14, a spring groove 15, and a sleeve rod 16. Ladder-shaped guide rail 17, such as figure 1 As shown, the brake unit connection shell 10 is installed on the brake unit hydraulic shell 11 and the internal cavity of the two communicates; the first brake unit 3 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com