LED (light emitting diode) display screen case front-back double-hole assembling structure

A LED display and cabinet technology, applied in the direction of instruments, identification devices, etc., can solve the problems of small space for LED display installation, LED display cannot be spliced, and affect the visual effect of the display, so as to achieve flexible assembly methods, Effect of preventing deformation or displacement and small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

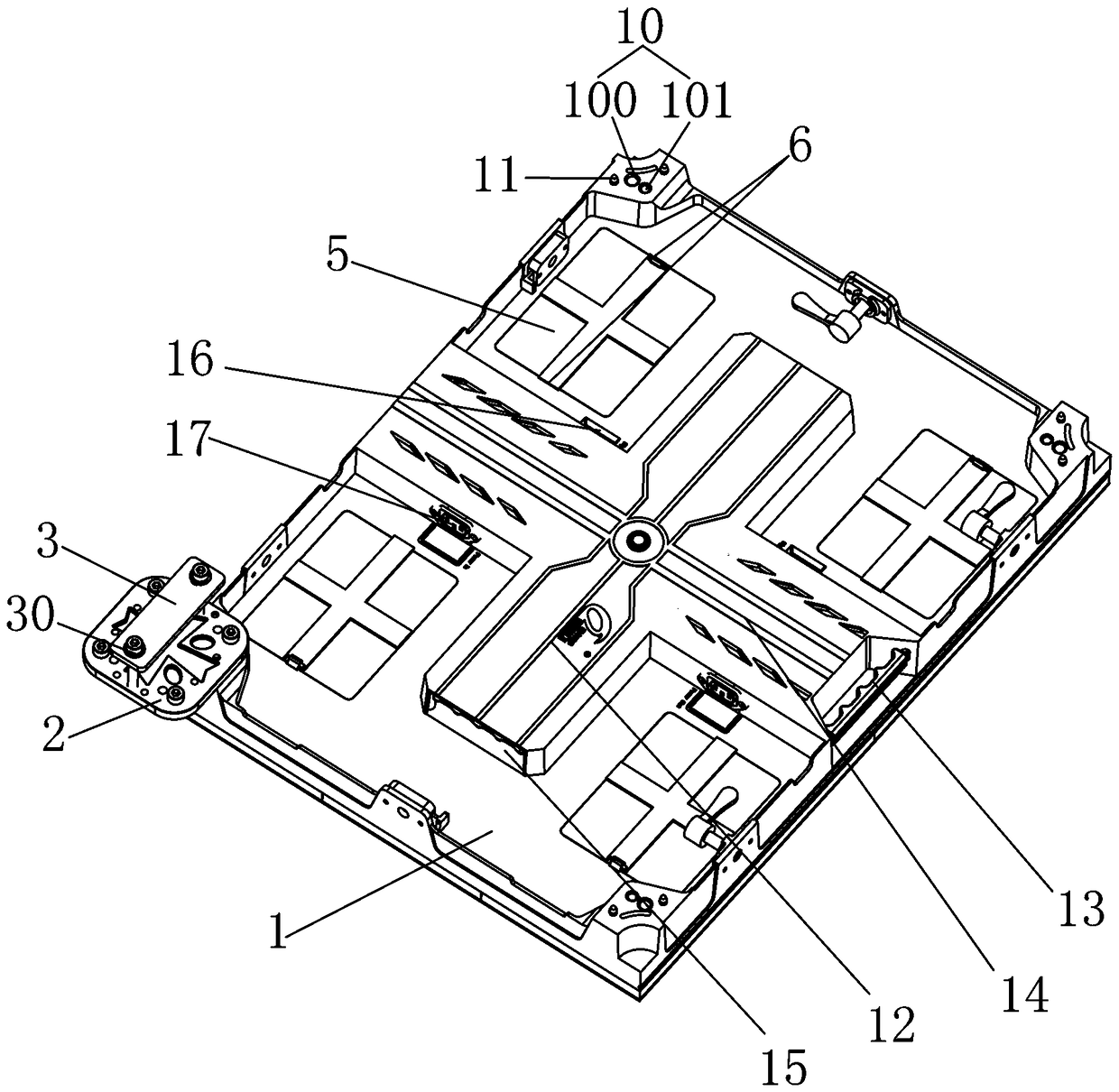

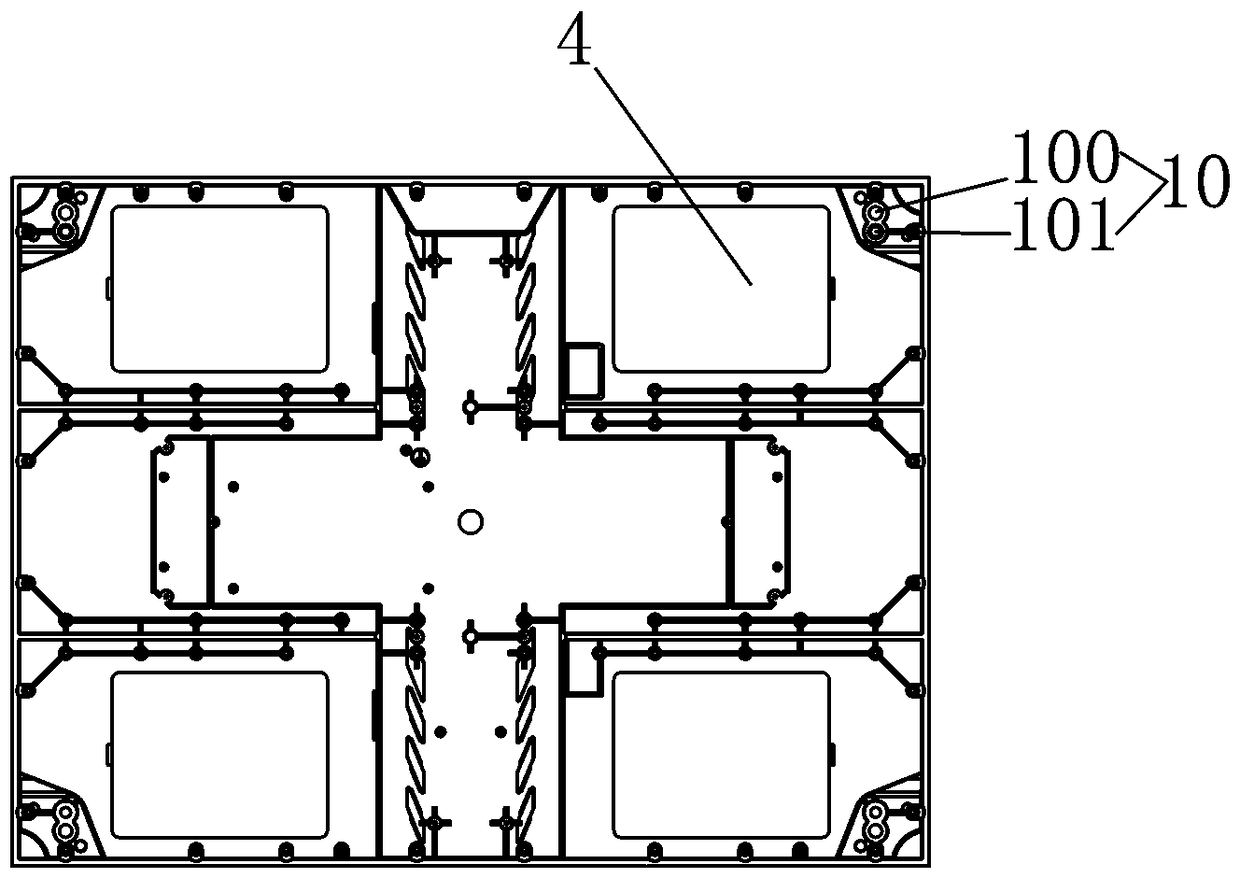

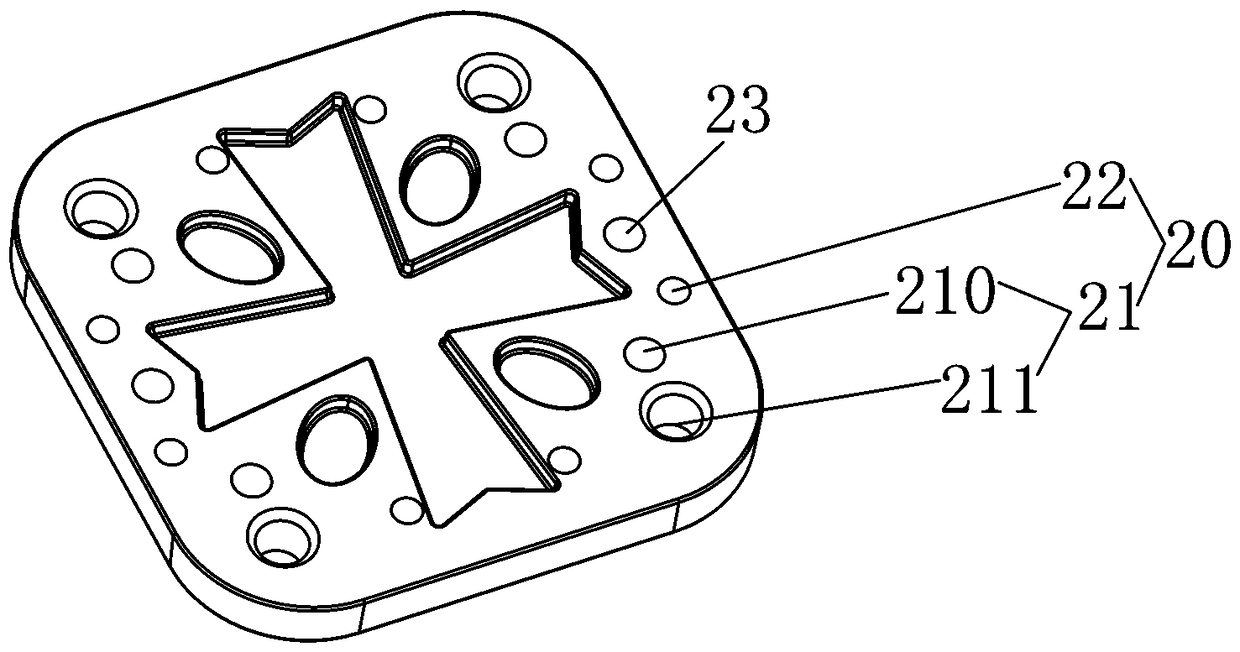

[0036] refer to Figure 1 to Figure 5 , a double-hole splicing structure at the front and back of the LED display box, including a backboard 1 and a splicing piece 2 located on the back of the backboard 1, and four corners of the backboard 1 are provided with splicing holes 10 penetrating through the backboard 1 The splicing piece 2 is divided into four positioning units 20 by mutually perpendicular X symmetry axes and Y symmetry axes, and two adjacent positioning units 20 are distributed symmetrically along the X symmetry axis or the Y symmetry axis, e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap