Honeycomb core material optimization cutting processing method

A technology of cutting processing and honeycomb core, which is applied in the field of mechanical processing, can solve the problems of weak rigidity, easy deformation of honeycomb core material, poor cutting quality of honeycomb core material, etc., and achieve the effect of optimizing cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

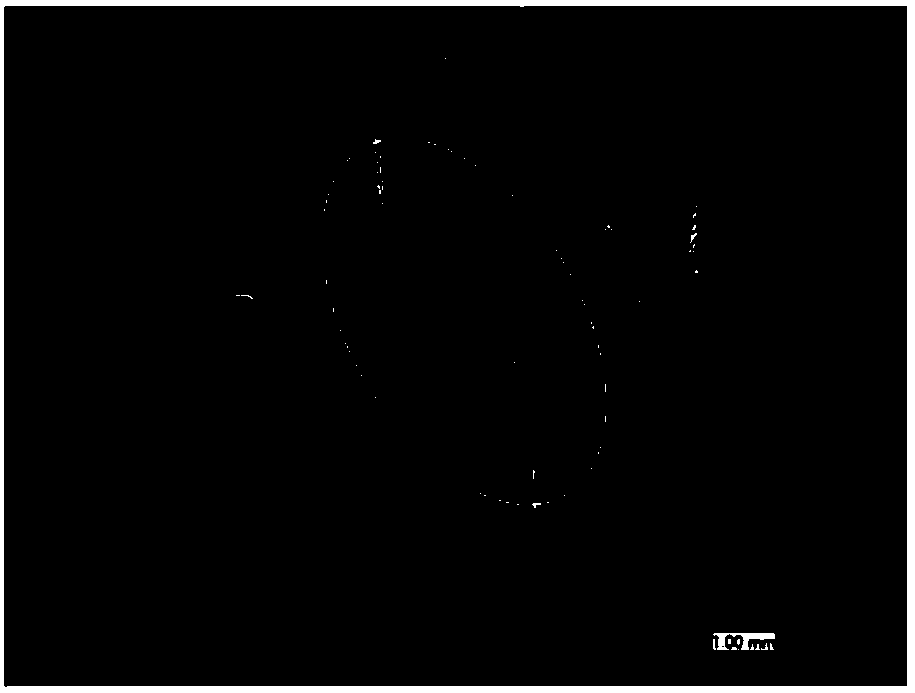

[0025] Such as figure 1 As shown, this embodiment provides a defect classification method and a characterization method using defect classification plus defect distribution angle to characterize all defects that occur in processing for the defect characteristics of honeycomb core material cutting processing, and based on test data, establishes The defect distribution map of the honeycomb core material and the optimal condition equation to determine the low defect of the honeycomb core processing, so as to obtain the optimized cutting parameters to avoid the occurrence of processing defects.

[0026] The honeycomb core processing defect characterization method and optimization method described in this embodiment include the following specific steps:

[0027] The first step is to collect the optical images of the processing defects of the honeycomb core obtained from the test, and figure 1 , attached figure 2 , attached image 3 And attached Figure 4 For comparison, combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com