A precision welding tool for battery tray side beams

A battery tray and precision welding technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of large human influence factors, shaking or shaking of the battery tray, affecting the product quality of the battery tray and welding processing efficiency, etc. problems, to achieve the effect of ensuring product processing quality, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

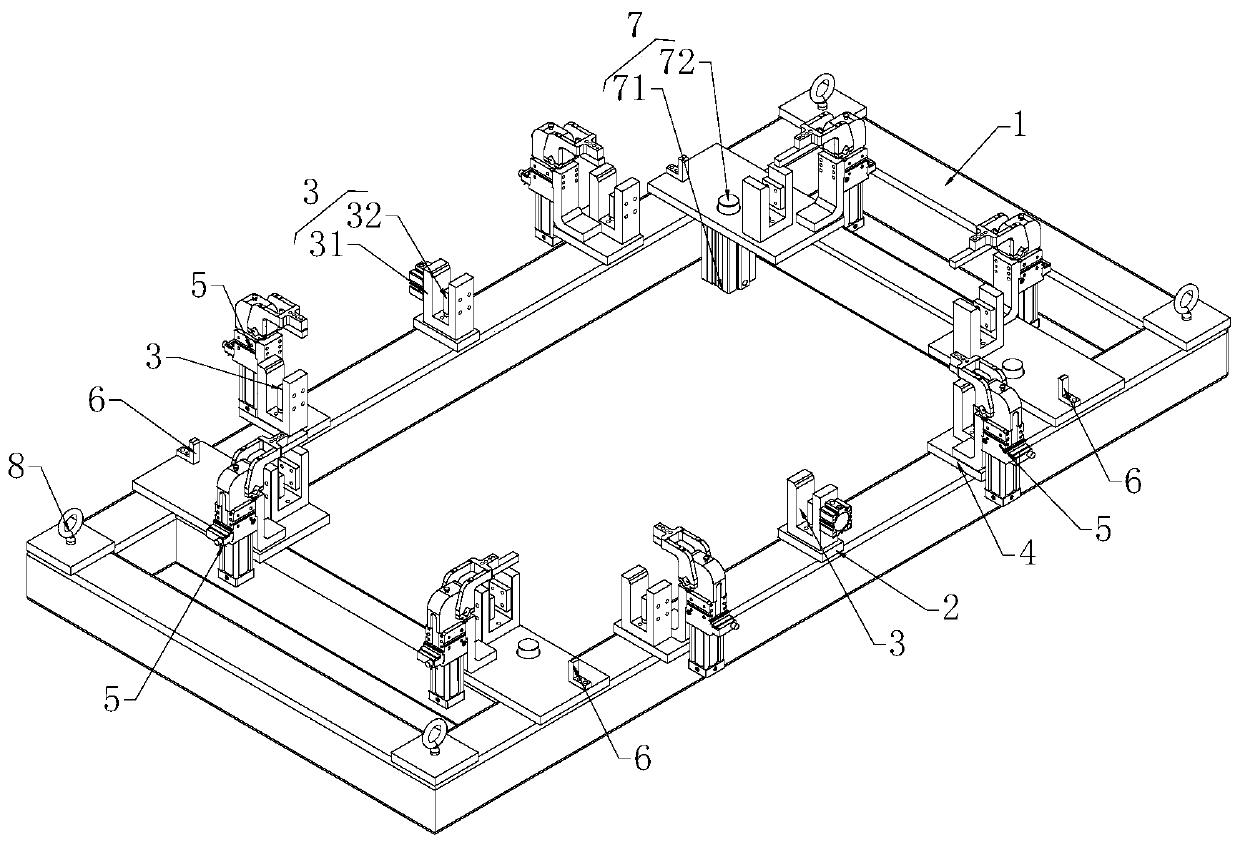

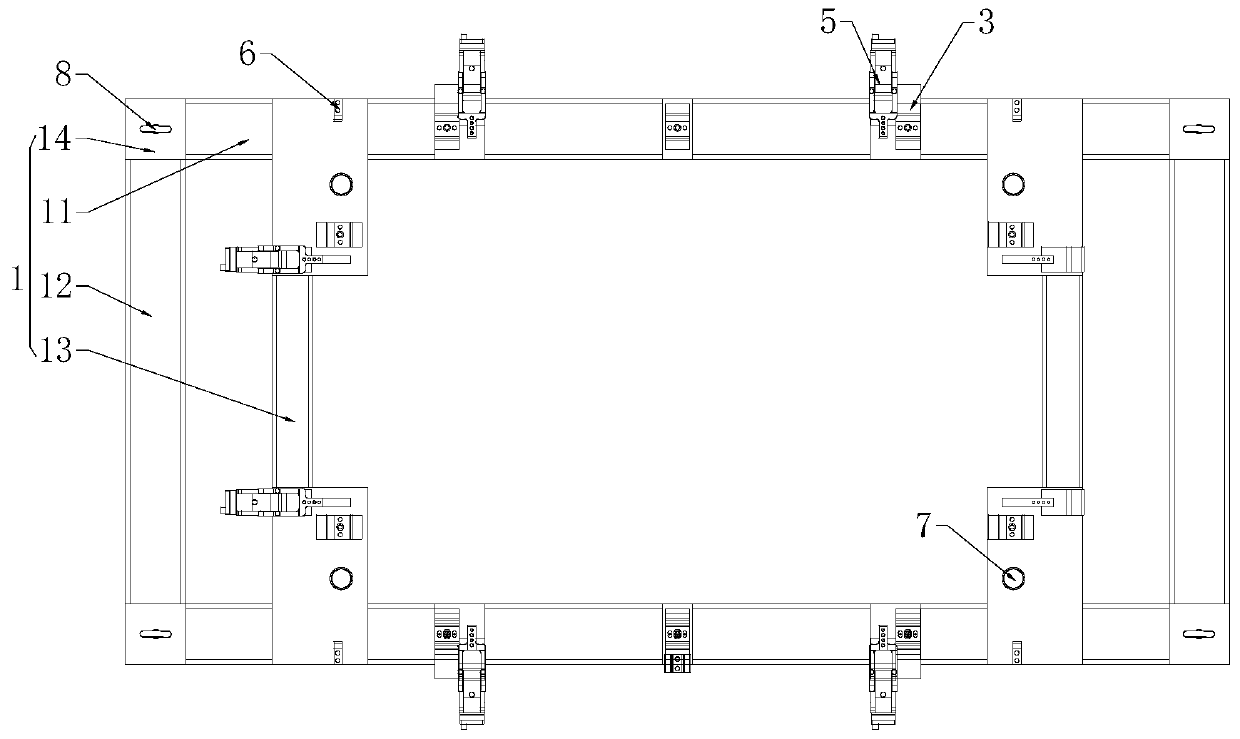

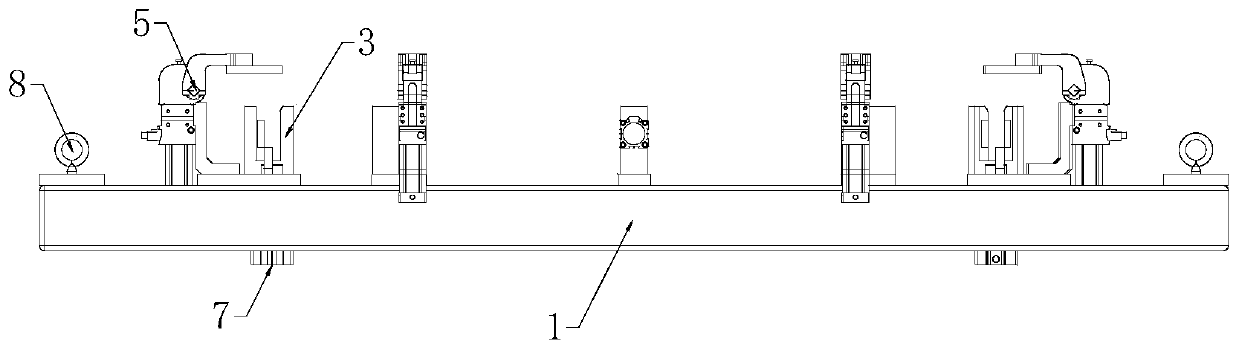

[0019] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] like Figure 1 ~ Figure 4 As shown, a precision welding tool for the side beam of the battery tray includes a base 1, including a base 1, and the base 1 is fixed with a plurality of sets of side limiting mechanisms 3 through a first backing plate 2, and a plurality of sets of side limiting mechanisms 3 is used to limit the side beams of the battery tray during welding and is distributed along the circumference of the base 1. There are also multiple sets of side limit mechanisms 3 fixed on the base 1 through the second backing plate 4 The matching pressing mechanism 5, and the pressing mechanism 5 is in close contact with the upper end surface of the side beam of the battery tray during welding, and the front and rear sides of the base 1 are respectively fixed with end surface limit mechanisms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com