A tire mold side plate and tire mold

A tire mold and side plate technology, applied in the field of tire mold side plates and tire molds, can solve the problems of reducing the service life of the mold, affecting the appearance quality of the tire, affecting the accuracy of the mold matching, etc., to prolong the service life, improve the brand value, enhance the aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

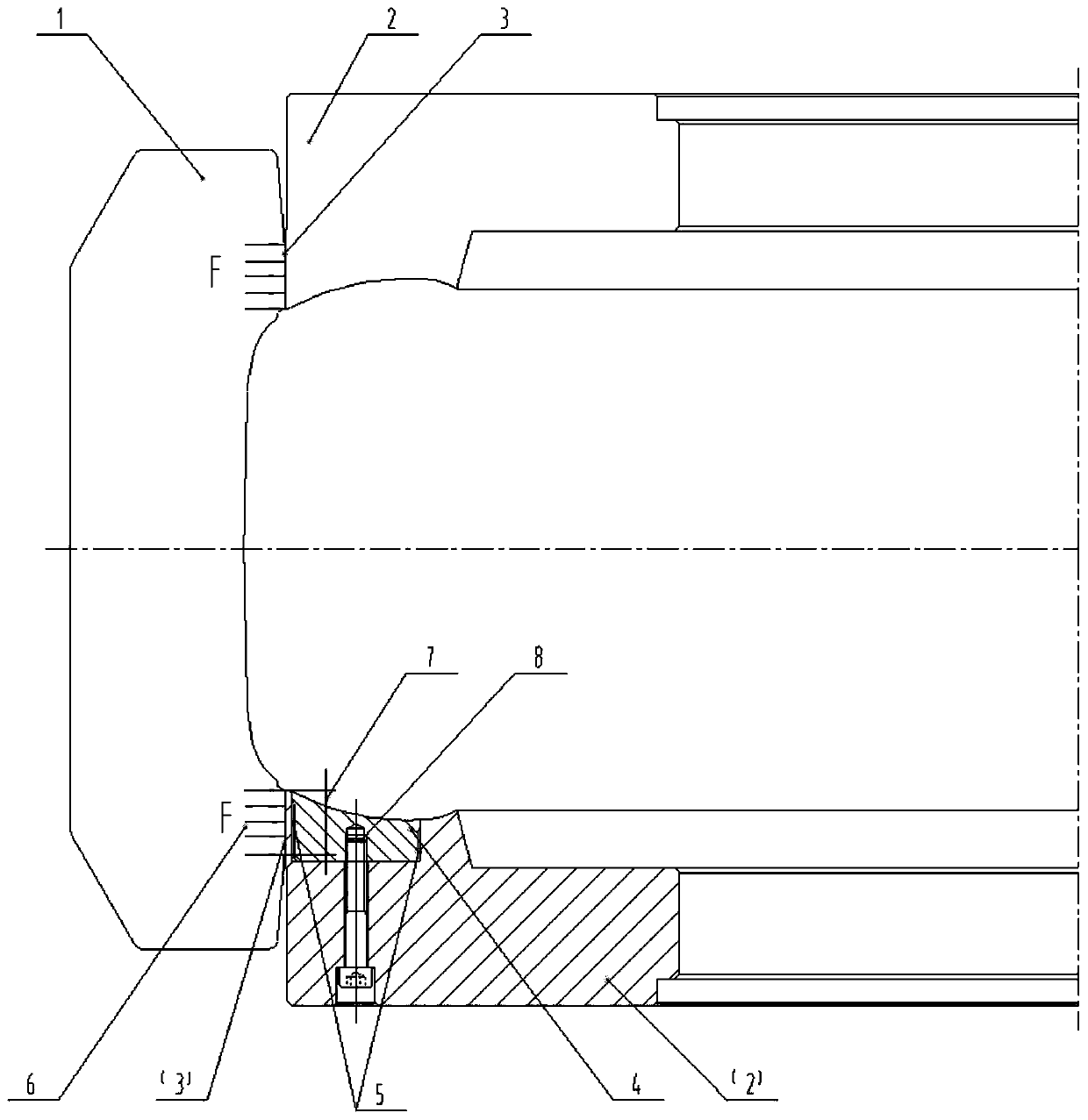

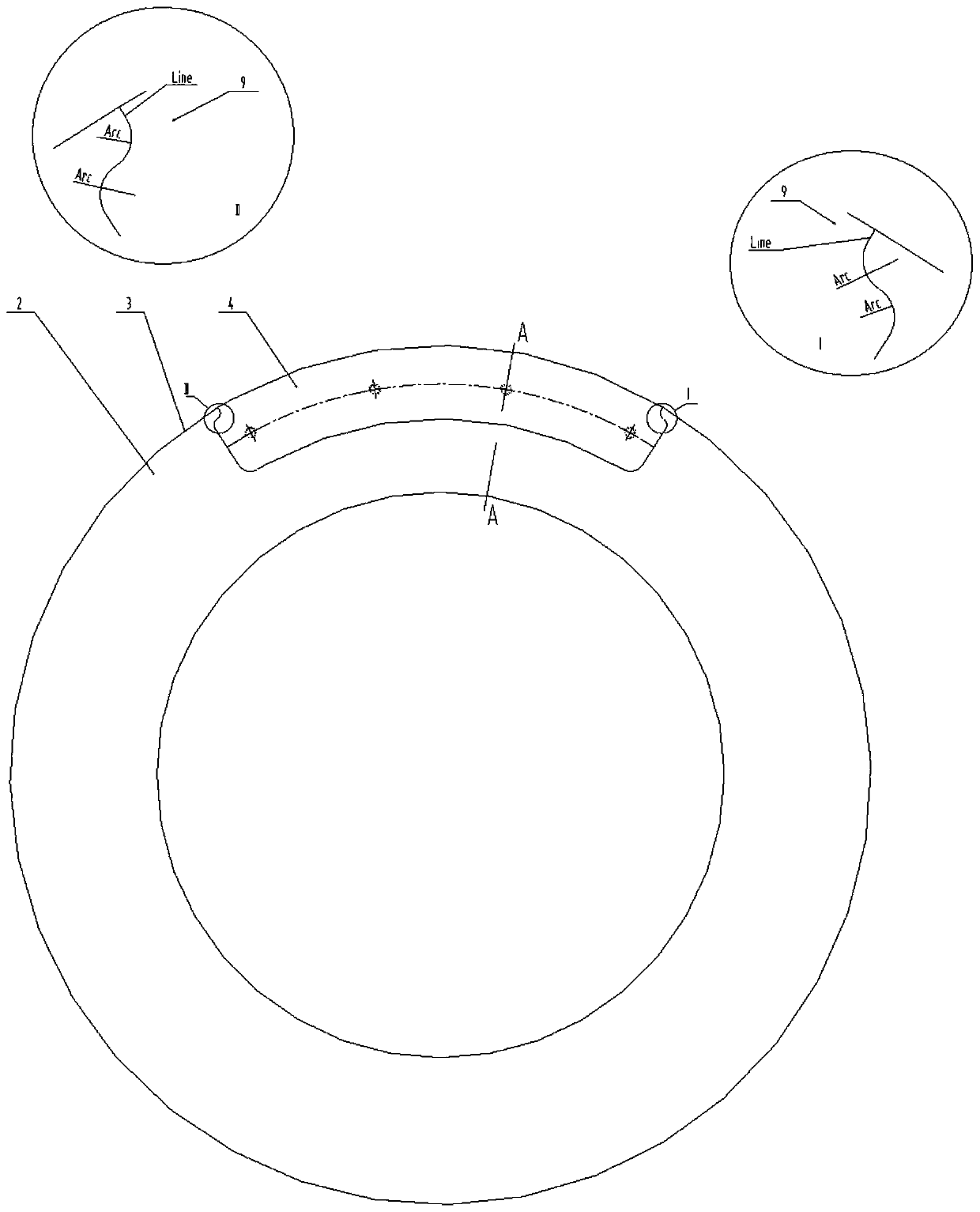

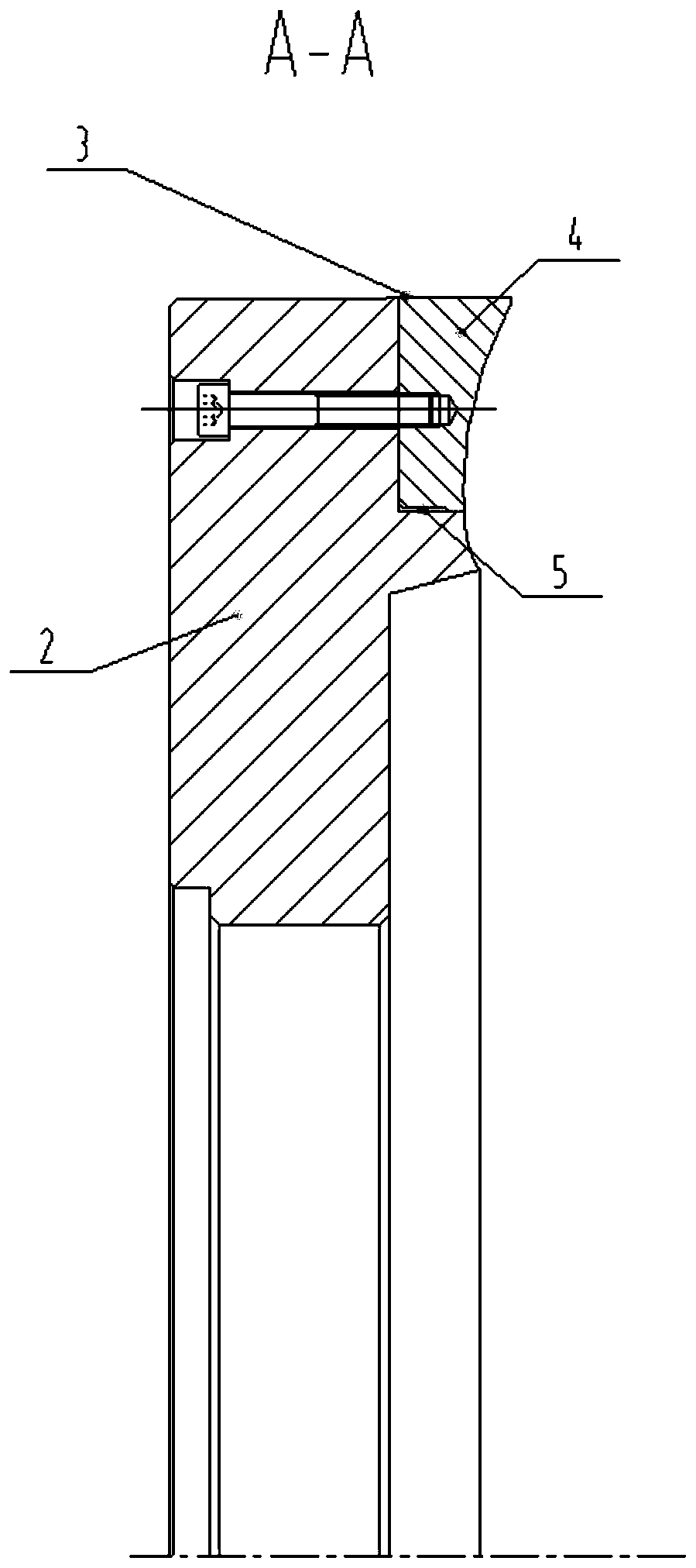

[0038] The first embodiment: as figure 2 As shown, the outer circle 3 of the side plate is used as the outer arc of the movable block 4, and the two corners of the outer arc of the movable block 4 are processed with positioning platforms 9.

[0039] The positioning platform 9 includes two circular arcs and two straight lines perpendicular to the outer arc of the movable block 4 .

[0040] Such as image 3 As shown, the two arcs are tangent to each other and are respectively tangent to the two straight sides to ensure a smooth transition and facilitate installation.

[0041] The straight line edge needs to be perpendicular to the outer arc of the movable block 4, which is convenient for processing.

[0042] The positioning table 9 can prevent the movable block 4 from moving in the circumferential direction and the radial direction on the side plate 2, and the positioning is accurate, so that the side plate 2 and the movable block 4 will not be dislocated.

[0043] This stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com