An electric stamping machine with a transmission mechanism

A technology of a transmission mechanism and a stamping machine, which is applied in the field of stamps, can solve the problems of complex structure, labor-intensive manual stamping, hand numbness, etc., and achieve the effect of simple structure, practicality, mass production, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

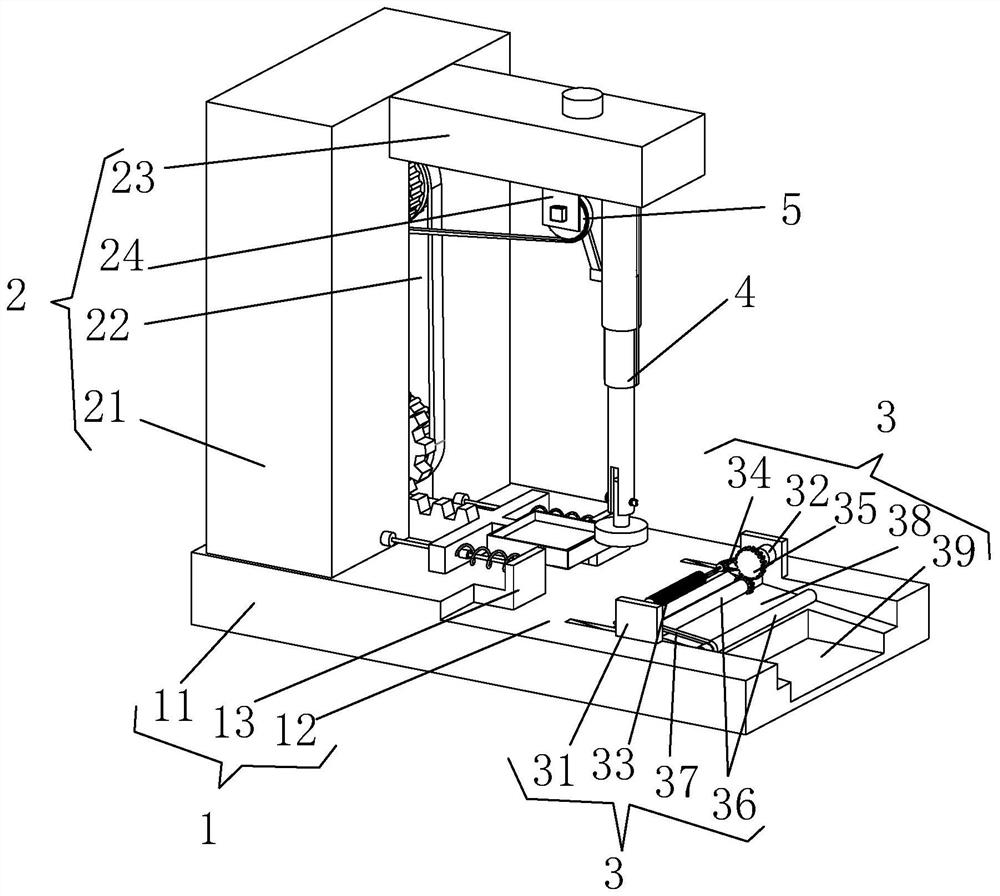

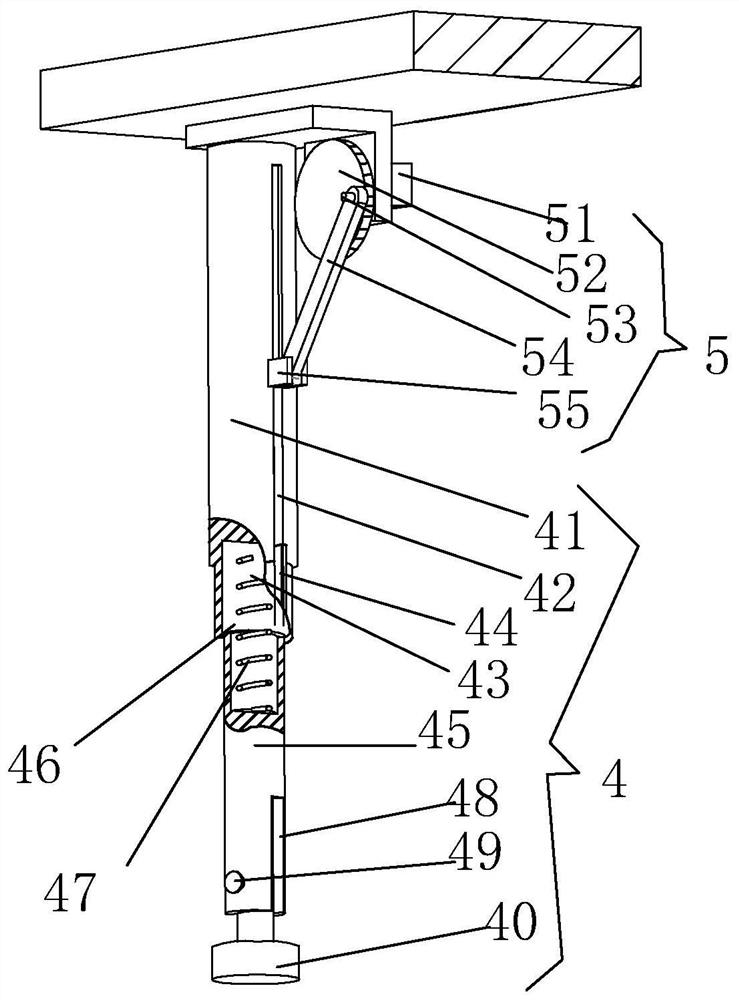

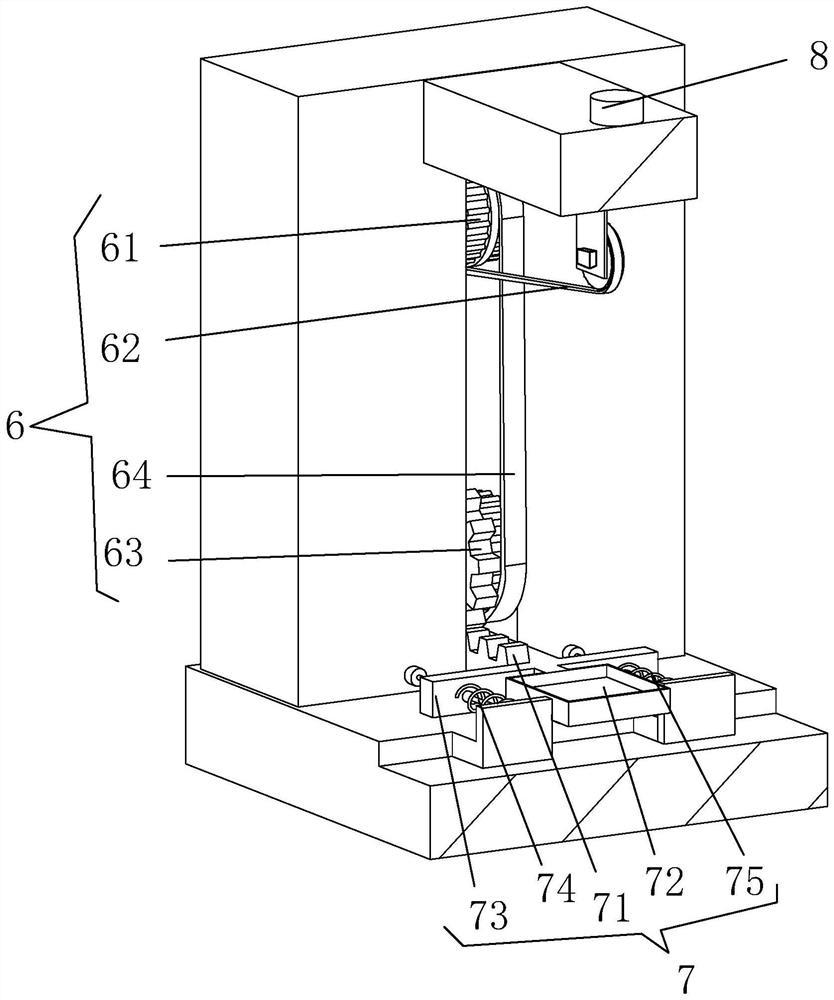

[0021] like Figures 1 to 3 As shown, an electric cover provided with a transmission mechanism is provided with a document feeder 3 in front of the stamping body 2, and a pop-up device 7 is provided inside the stamping body 2, and a transmission mechanism 6 is provided on the upper side of the pop-up device 7 , a stamping device 4 is provided on the front side of the transmission mechanism 6, and a pulling device 5 that allows the stamping device 4 to move up and down is provided between the stamping device 4 and the transmission mechanism 6, and the transmission mechanism 6 is connected to the pulling device at the same time 5 and the pop-up device 7, when working, the pulling device 5 drives the stamping device 4 to stamp on the paper, after the stamping, the pop-up device 3 is released, and the stamping device 4 continues to operate, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap