Electric stamping machine

A stamping machine and electric technology, applied in the field of stamping machines, can solve problems such as hand numbness, lack of mass production, manual stamping consumes manpower, etc., and achieves convenient use, simple structure, practicality and mass production sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

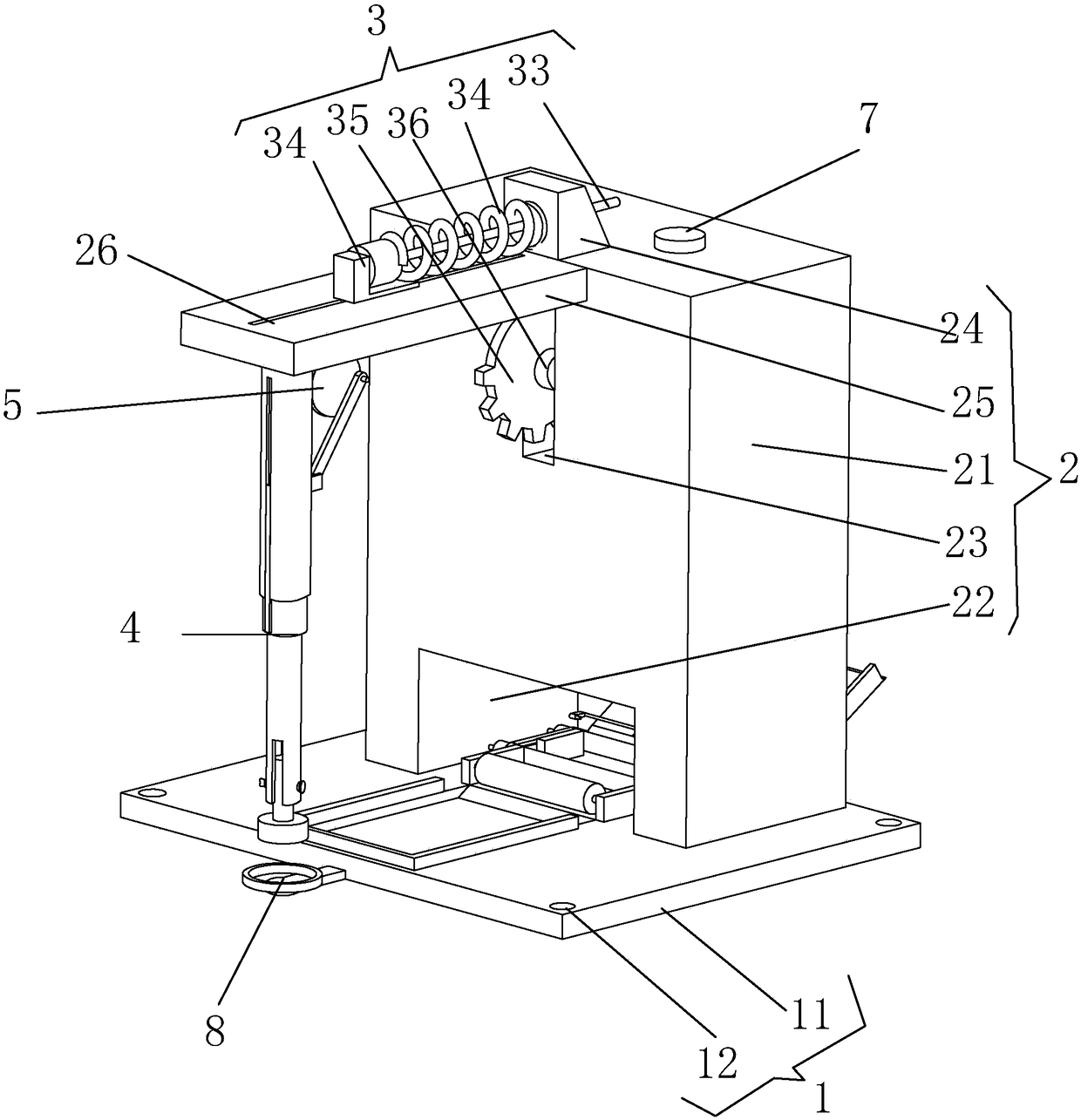

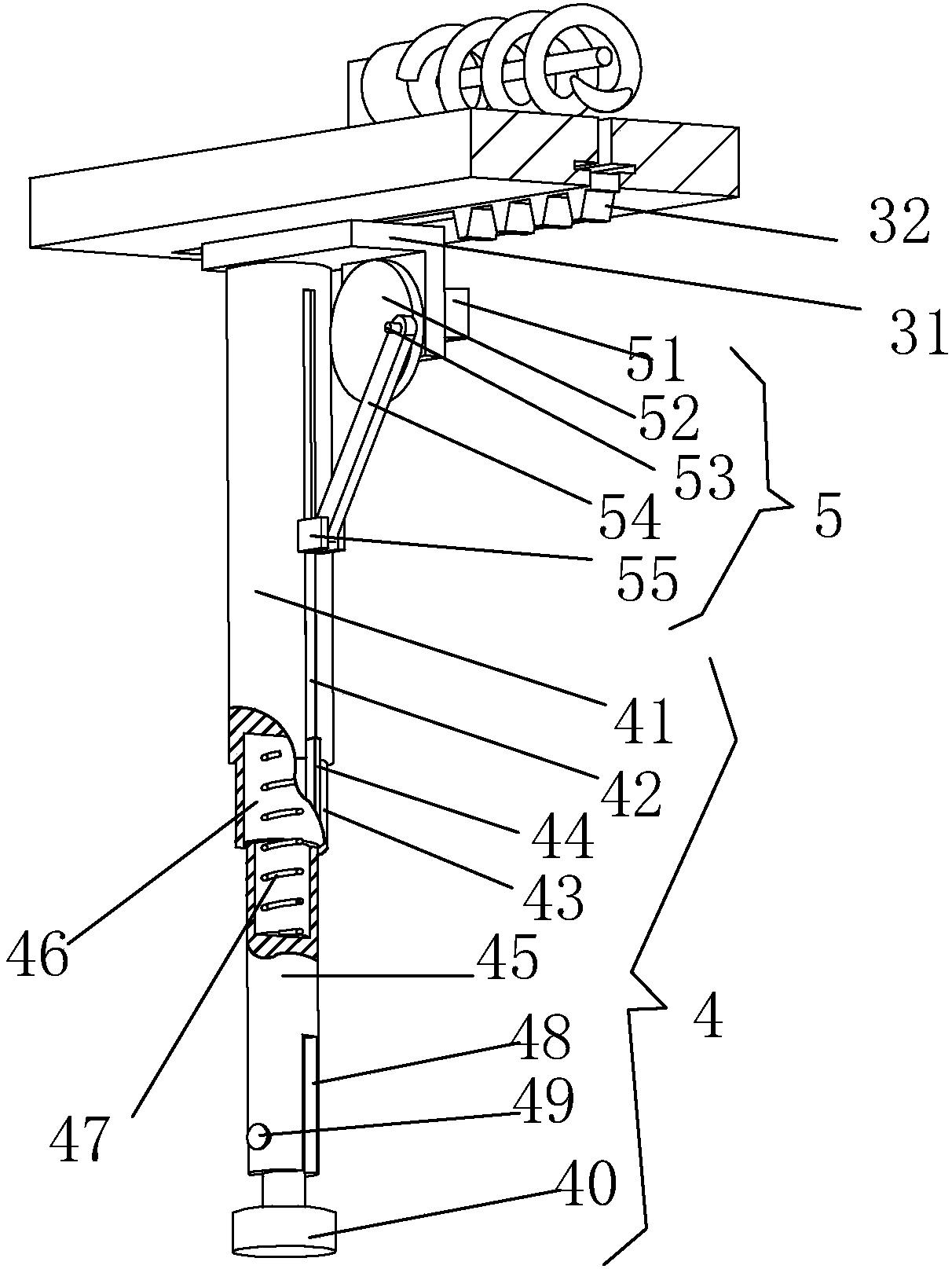

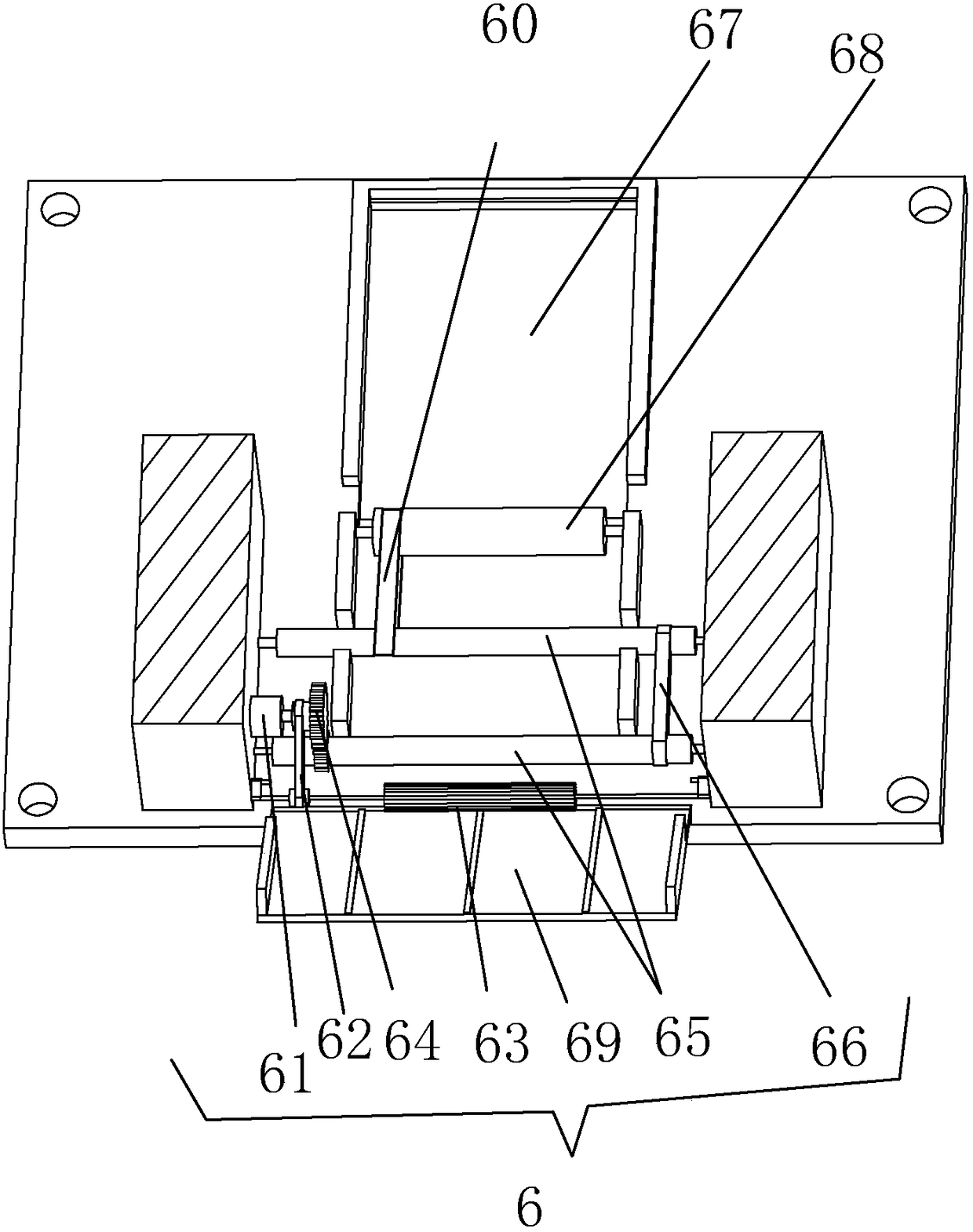

[0021] Such as Figures 1 to 3 A kind of electric stamping machine shown, comprises base 1, is provided with stamping body 2 on described base 1, is provided with feeder 6 under stamping body 2, is provided with spring on stamping body 2. Return device 3, be provided with stamping device 4 under described rebounding device 3, be provided with the pulling device 5 that can allow stamping device 4 to move up and down between stamping device 4 and rebounding device 3, during work, input Manuscript device 6 sends out the paper, pulling device 5 drives stamping device 4 to stamp on the paper, after stamping, springback device 3 resets stamping device 4, pulling device 5 drives stamping device 4 to press down and stick ink pad, So back and forth.

[0022] The base 1 described in the present invention includes a base plate 11, and the base pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap