Cantilever type armrest

A kind of armrest, suspension technology, applied in the field of auto parts, can solve the problems of armrests that cannot be adjusted, passengers cannot be placed flat, and armrests are far away.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

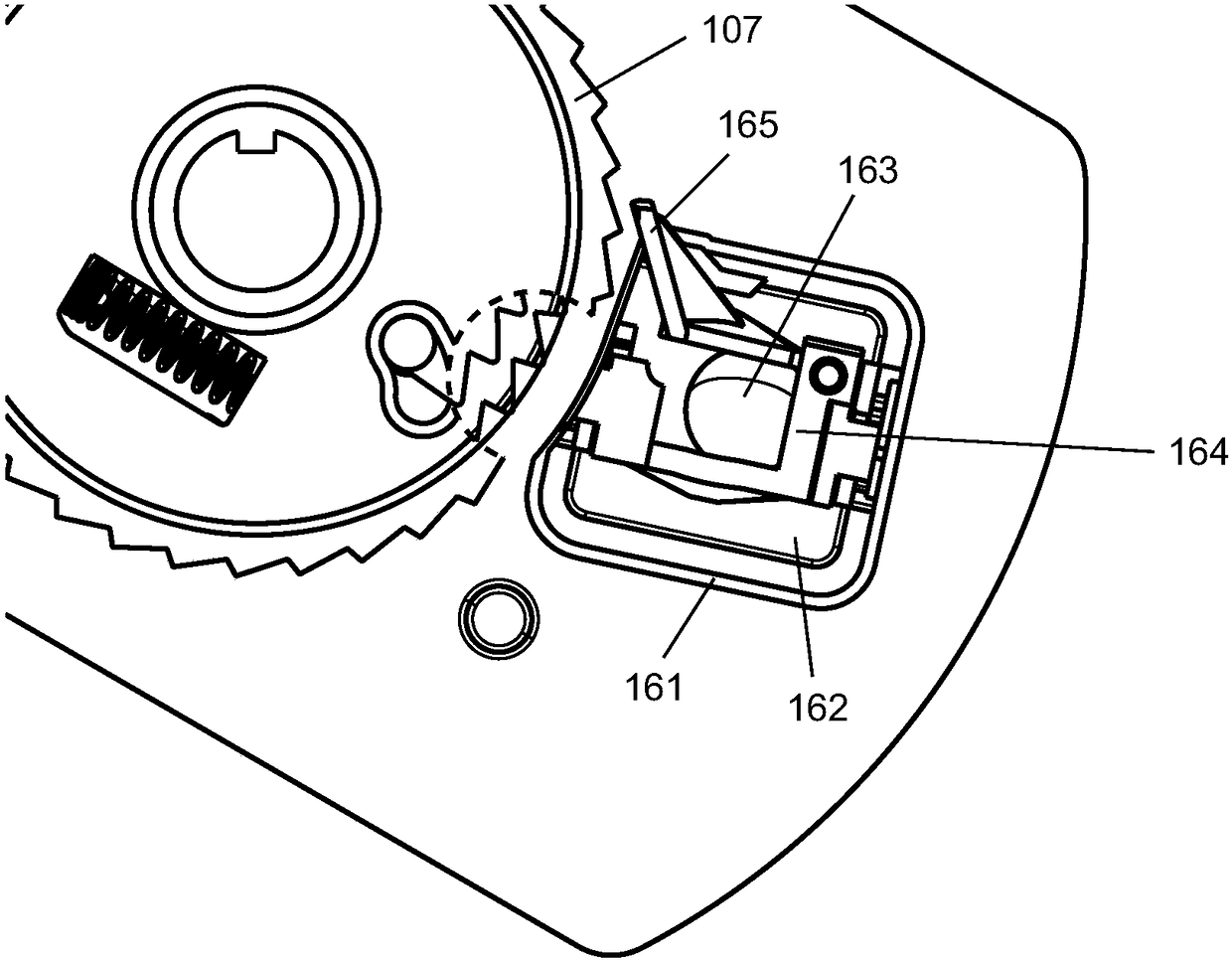

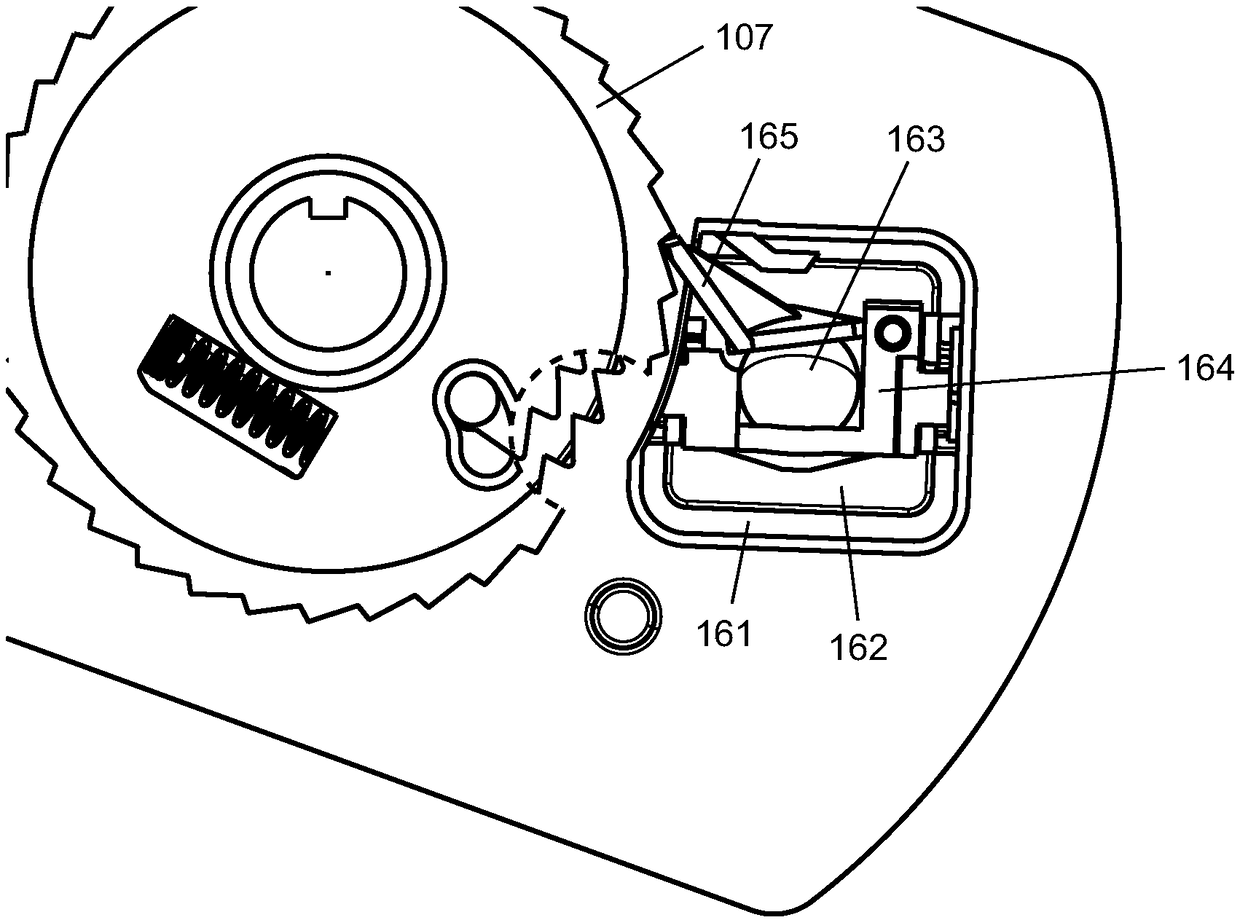

[0018] The invention proposes a suspended armrest, the armrest is installed on the back of the seat, the armrest has a gravity component and a locking mechanism, the gravity component rotates with the armrest, the armrest is located at an inclined position, the gravity component unlocks the locking mechanism, and the armrest can move towards the horizontal position Turn, the armrest is in the horizontal position, the gravity assembly locks the locking mechanism, and the armrest is locked in the horizontal position.

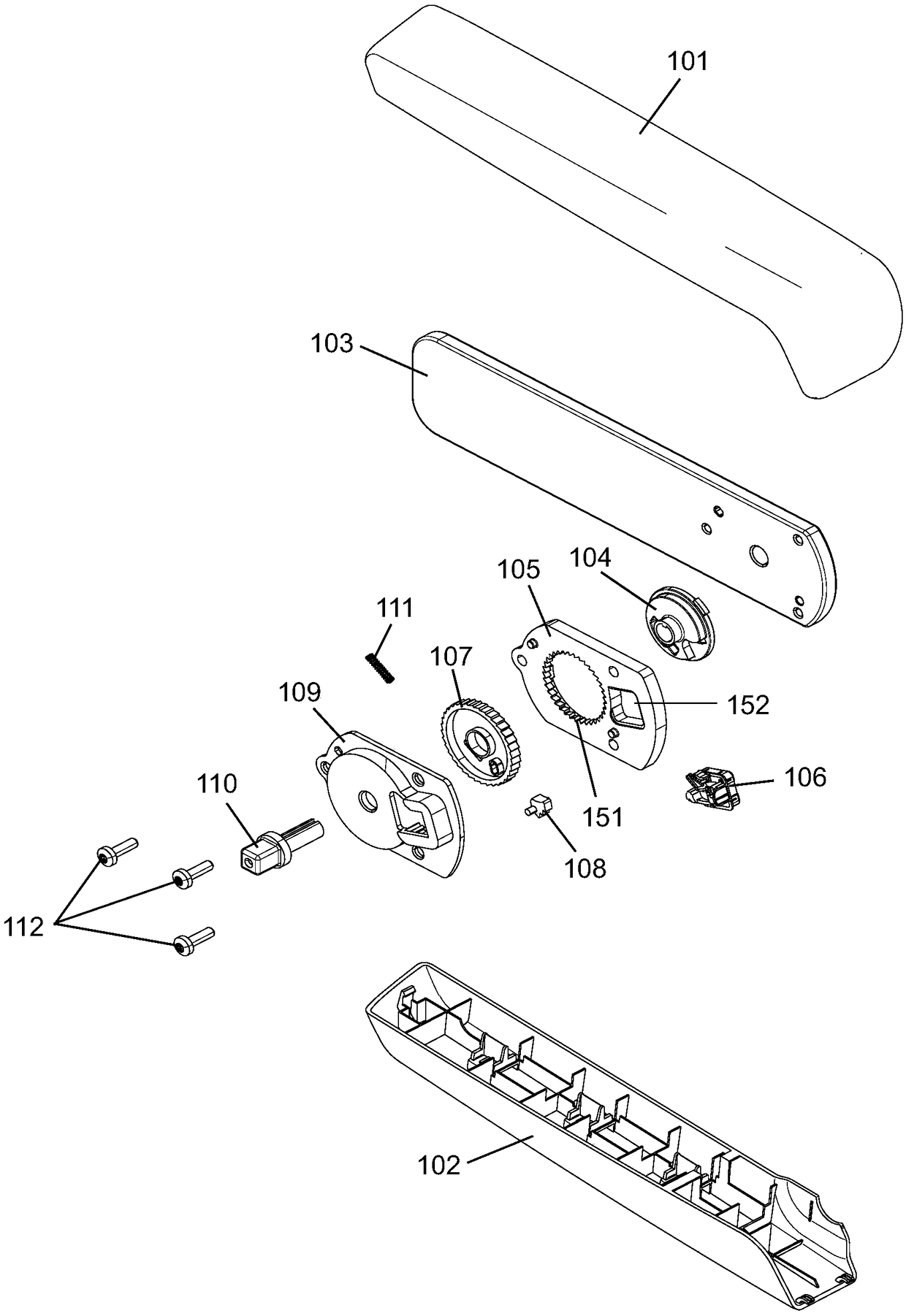

[0019] refer to figure 1 as shown, figure 1 Disclosed is an exploded structure diagram of a suspended handrail according to an embodiment of the present invention. As shown in the figure, the suspended armrest includes: an upper armrest cover 101, an armrest lower cover 102, an armrest body 103, a bearing 104, an inner tooth plate 105, a gravity component 106, a thumb wheel 107, a pawl 108, a cover plate 109 and a shaft 110. The armrest upper cover 101 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com