Simply assembled and disassembled pipeline connecting piece

A connection piece, a simple technology, applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc., can solve the installation requirements of scientific installation process, no qualitative improvement in operability, and direct push connection structure High, stainless steel pipe use cost increases, etc., to achieve the effect of simplifying the installation and operation process, stable fixing effect, and wide application in the installation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

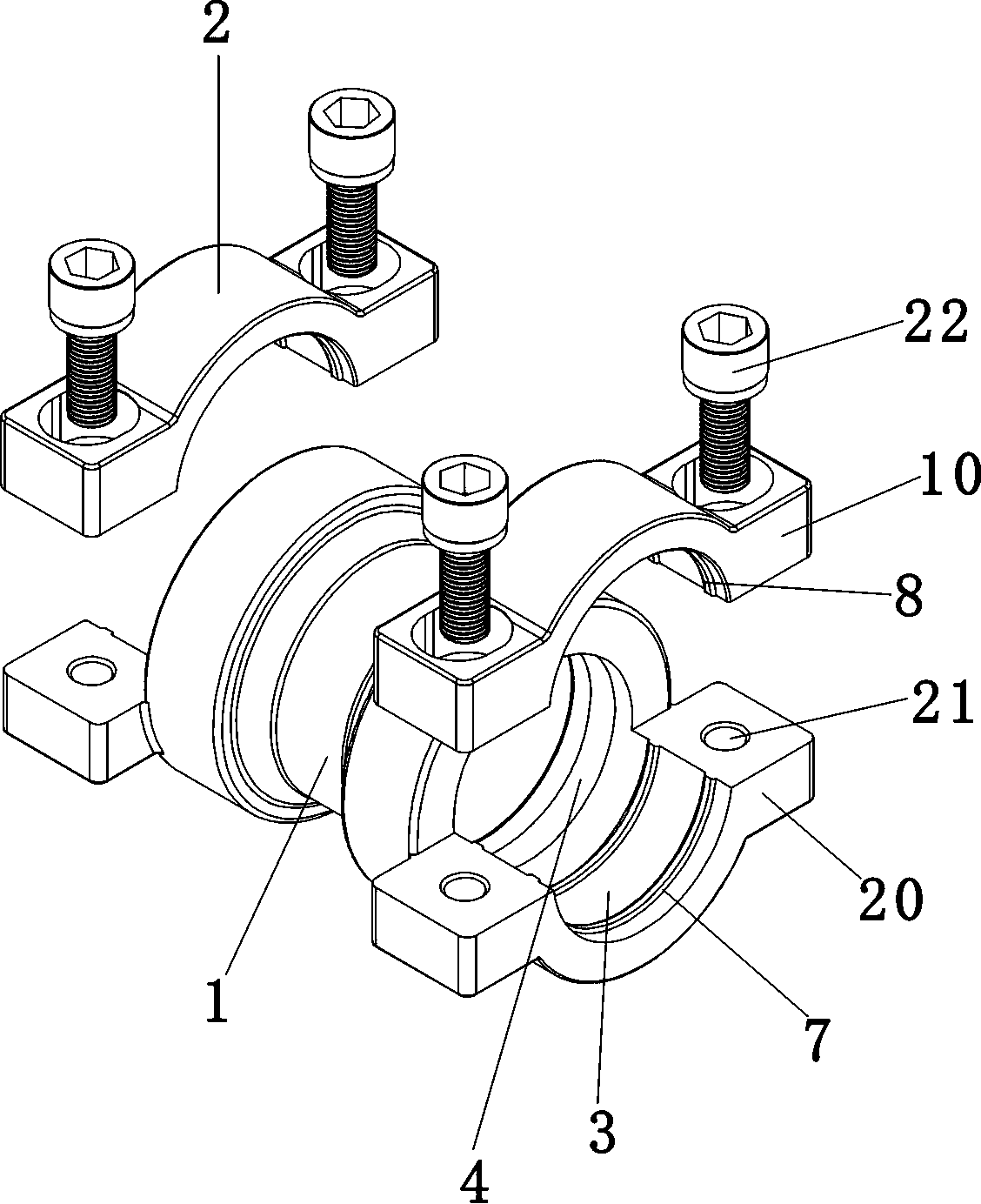

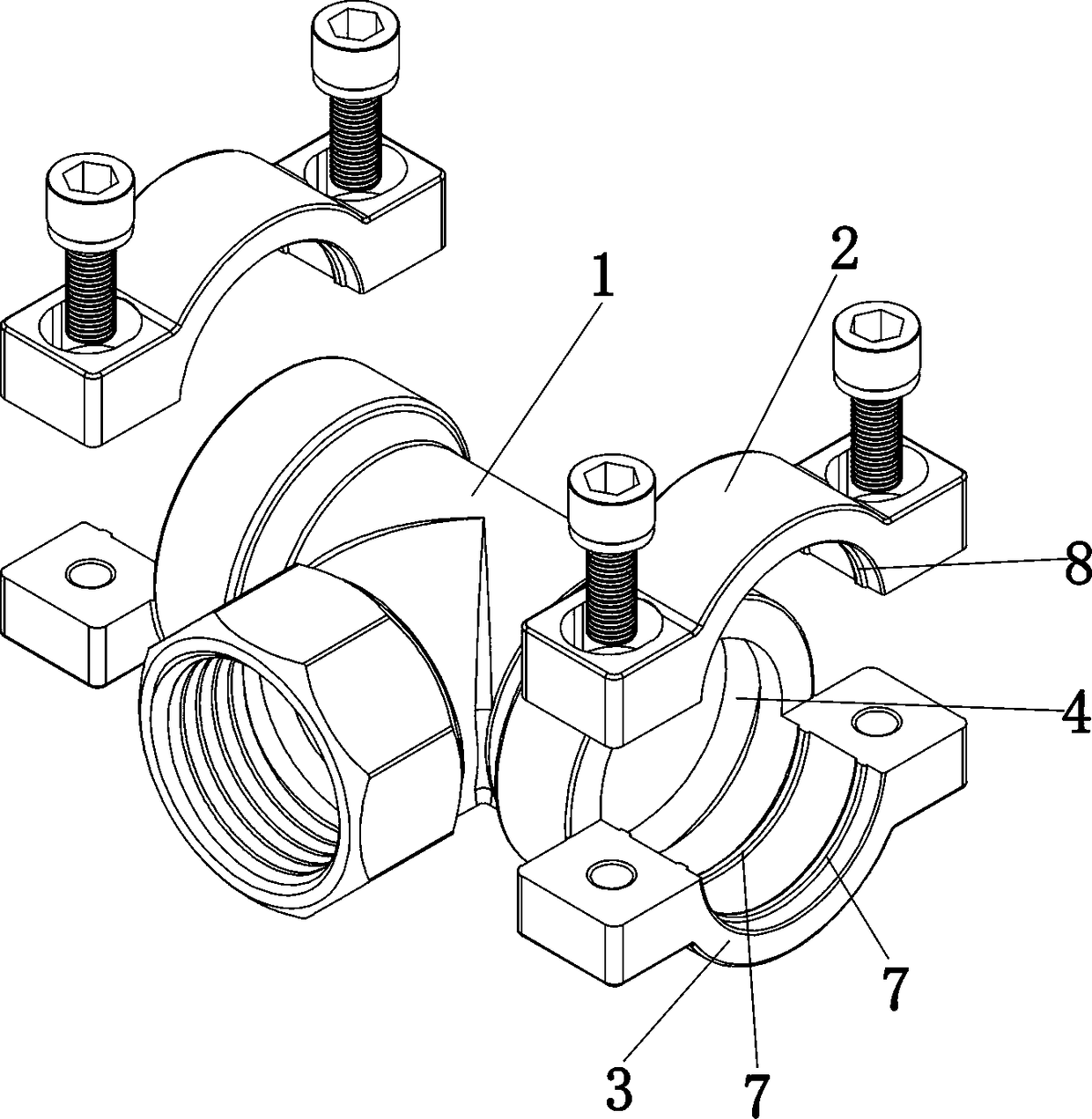

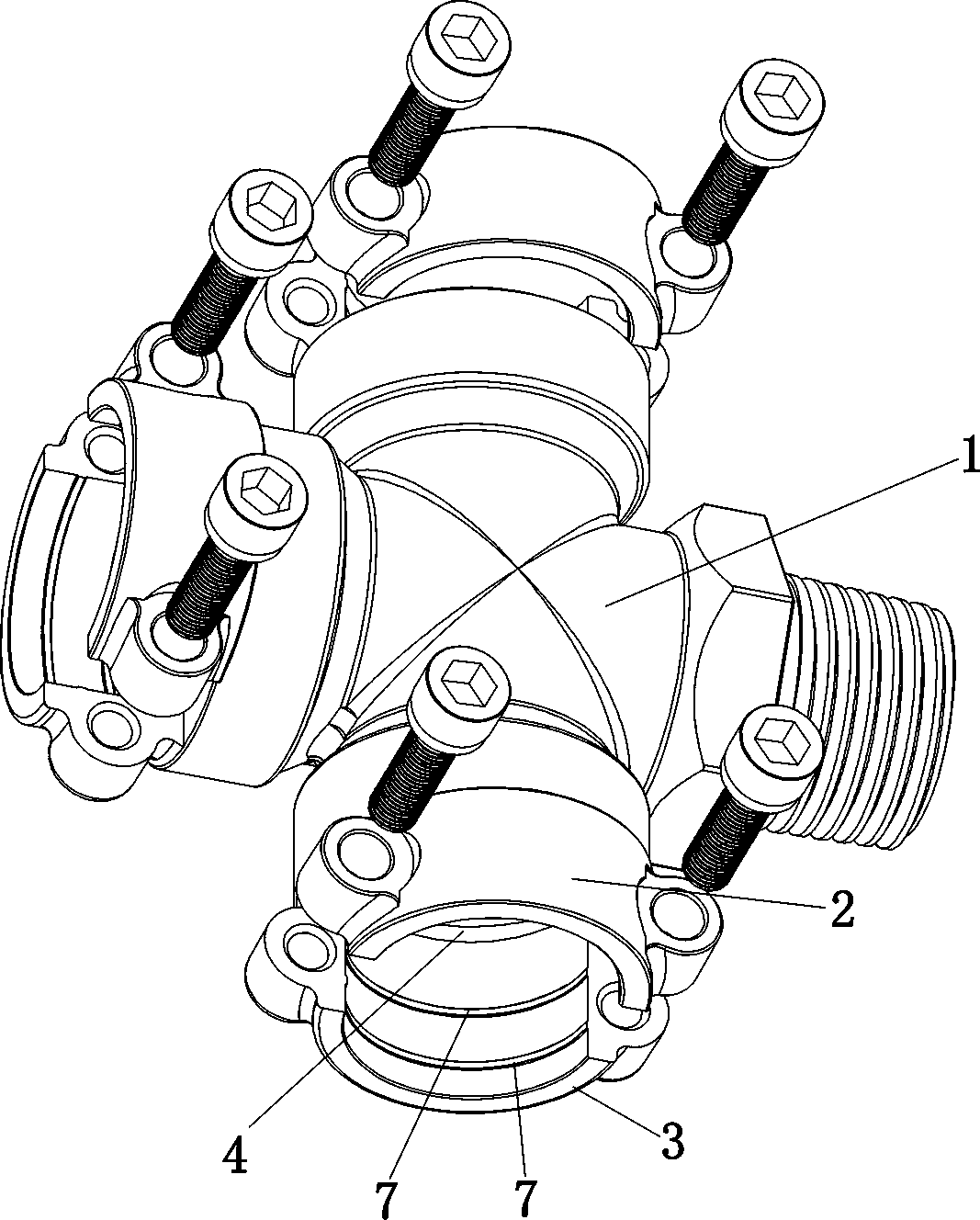

[0031]A set of connector series products for stainless steel pipes, including straight through, 45º elbow, 90º elbow, tee, cross, and various forms of variable diameter pipe products, etc. The structure of each product includes the joint body 1, the pipe Ferrule piece 2. as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, the joint body 1 is a hollow structure, and at least one opening is a circular insertion opening, which extends outwards at the insertion opening to form a semi-circular sleeve portion 3 . Other openings of the joint body can be the same embedded openings, or threaded joints with external thread structure or internal thread structure. figure 2 , attached image 3 And attached Figure 4 Structure.

[0032] A first sealing groove 4 is formed on the inner wall surface of the joint body close to the sleeve portion, for embedding a first sealing ring 5 of elastic material. The shape of the sealing ring is as atta...

Embodiment 2

[0036] A stainless steel pipe connecting flange, as attached Figure 8 As shown, it is composed of a flange 30 and a joint 31 , the inner wall of the joint 31 is formed with a first sealing groove 311 , and the first sealing ring is installed; Two parallel raised ribbed rings 321 are formed on the inner wall of the sleeve part, and two ear parts are formed on the outer side and at the diameter position, each ear part is pierced with a mounting hole 33 . A semi-annular pipe sleeve hoop piece 34 also forms two parallel raised ribbed rings 341, forming a closed ring structure with the raised ribbed rings 321 of the pipe sleeve portion. Tube ferrule pieces are also attached to the ears, creating mounting through-holes 35 .

[0037] When the connecting flange of this embodiment is used, the pipe to be connected is inserted into the flange joint and inside the first sealing ring. Then the pipe sleeve hoop piece is set on the pipe sleeve part, the connected pipe is clamped, and the...

Embodiment 3

[0039] A pipe cap for stainless steel pipes, as attached Figure 9 As shown, it is composed of a cap body 40 and a tube sleeve hoop piece 41 , the cap body is cylindrical, one end of which is closed, and the other end extends outward, forming a semi-circular tube sleeve portion 42 . The pipe sleeve hoop piece 41 is also semi-circular, and is installed on the pipe sleeve portion to form a cylindrical pipe sleeve structure. Both the pipe sleeve part and the pipe sleeve hoop piece are connected to the ear part 43, and are formed with mounting holes, which are inserted and fastened by bolts 44. The structure of the first sealing groove and ribs on the inner wall of the cap is the same as that of Example 1, see the attached figure 1 To attach Figure 4 shown.

[0040] The pipe cap of this embodiment is fitted to the end of the pipe to close the pipe. The basic operation of the installation and use method is the same as that of Embodiment 1, please refer to the description of Em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com