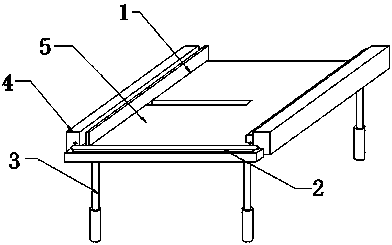

Photovoltaic power generation system installation structure applied to roof with steel-frame structure

A photovoltaic power generation system and installation structure technology, applied in the direction of photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of inability to apply photovoltaic panels of different specifications, inability to protect photovoltaic panels, and large use limitations, and achieve Increase the use range, facilitate automatic reset, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

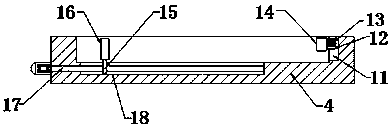

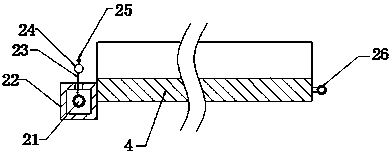

[0023] Specific implementation method: when in use, the operator first pulls the pressing block 14 upward, and the pressing block 14 drives the push plate 12 to move upward in the guide groove 11, and the push plate 12 moves to squeeze the spring 13, causing the spring 13 to elastically deform, and then the photovoltaic The board is placed in the card slot 5, and the right end surface of the photovoltaic panel is closely attached to the right side of the card slot 5, and then the pressure block 14 is sent away, and the spring 13 pushes the push plate 12 to move downward under the action of the resilience force. The push plate 12 moves downward to drive the pressure block 14 to move downward, and then the pressure block 14 is closely attached to the photovoltaic panel, and then the motor is run, and the motor drives the screw rod 17 to rotate in the groove 18, and the ball nut pair controls the rotation of the screw rod 17 The motion is converted into linear motion, the nut seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com