a discharge structure

A technology of feeding materials and articles, which is applied in the field of medical devices, can solve the problems of being unable to meet the needs of the medicine box discharging, the spring force is difficult to accurately control, and the feeding process is complicated, so as to achieve low total cost, short discharging time, and efficient feeding. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

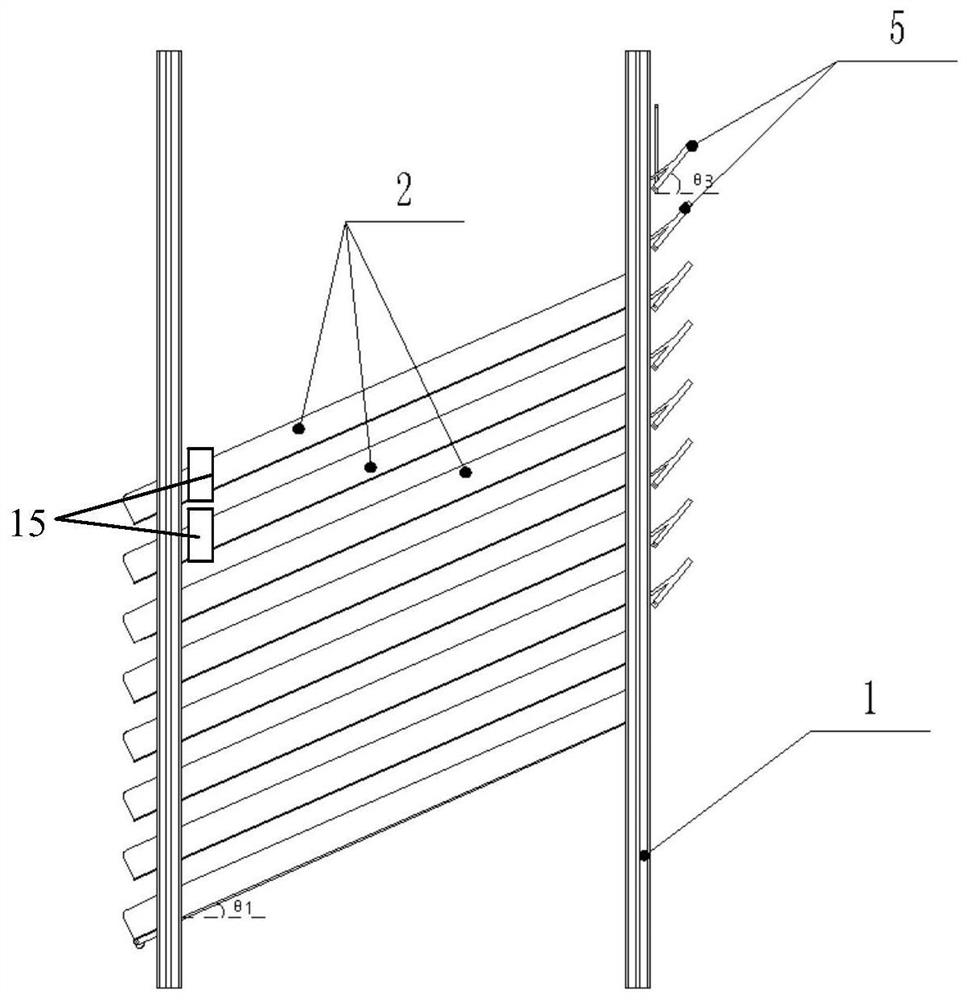

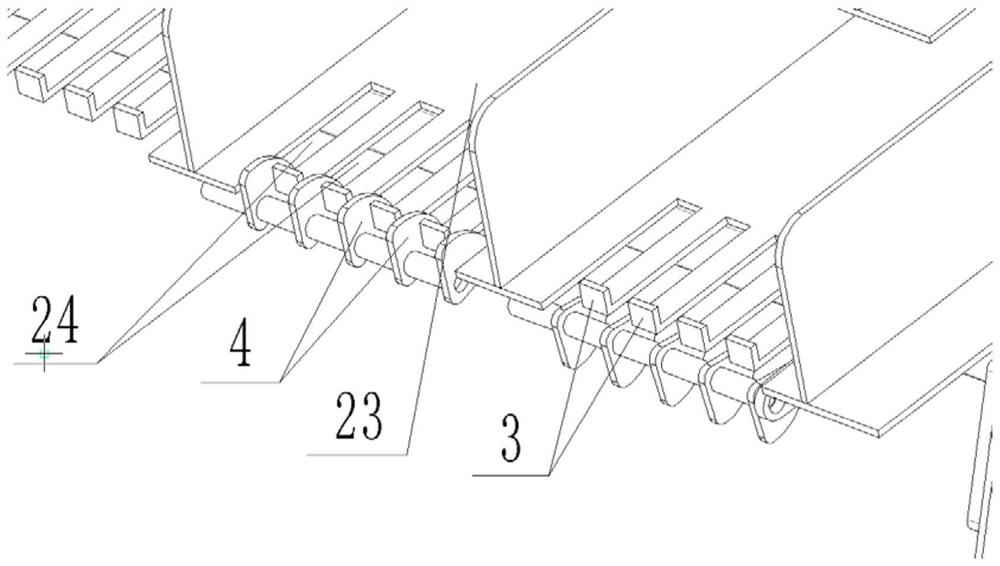

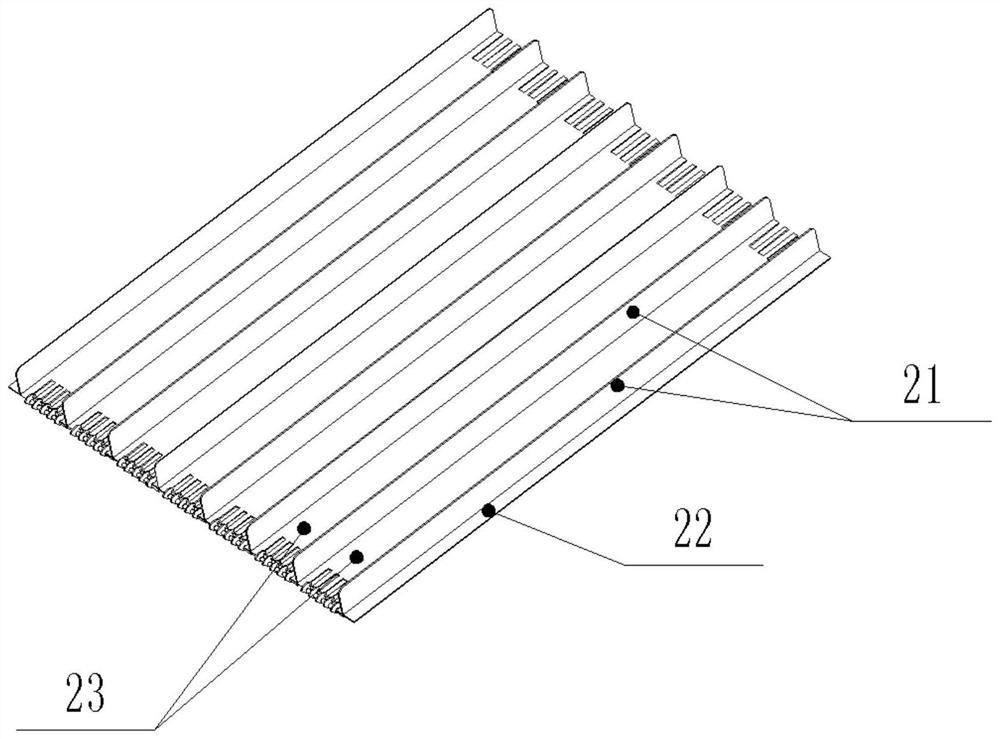

[0034] Such as Figure 1-2 As shown, the discharge structure of the present invention includes: a bracket 1;

[0035] At least one slideway 2, which is installed obliquely on the bracket 1, is used to support the items to be transported and make the items to be transported slide down by their own gravity; in this embodiment, the items to be transported include medicine boxes There can be multiple slideways 2, and they are arranged parallel to each other in the height direction. At the same time, in order to avoid being stuck between the two slideways 2 because the height of the item to be conveyed is too high, the distance between the slideways is 5-10cm (preferably 8cm), thus, the article to be conveyed can slide unimpeded in the gap between the two slideways 2; preferably, the inclination angle θ1 formed between the slideway 2 and the horizontal plane It is 15-60° (preferably 45°), so that the article can slide slowly and smoothly under the action of friction and gravity; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com