Multi-adjustment type plastic mold

A plastic mold and multi-adjustment technology, which is applied in the field of plastic production molds, can solve problems such as product strain and complex product structure, and achieve the effects of less tension, simple structure, and prevention of strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

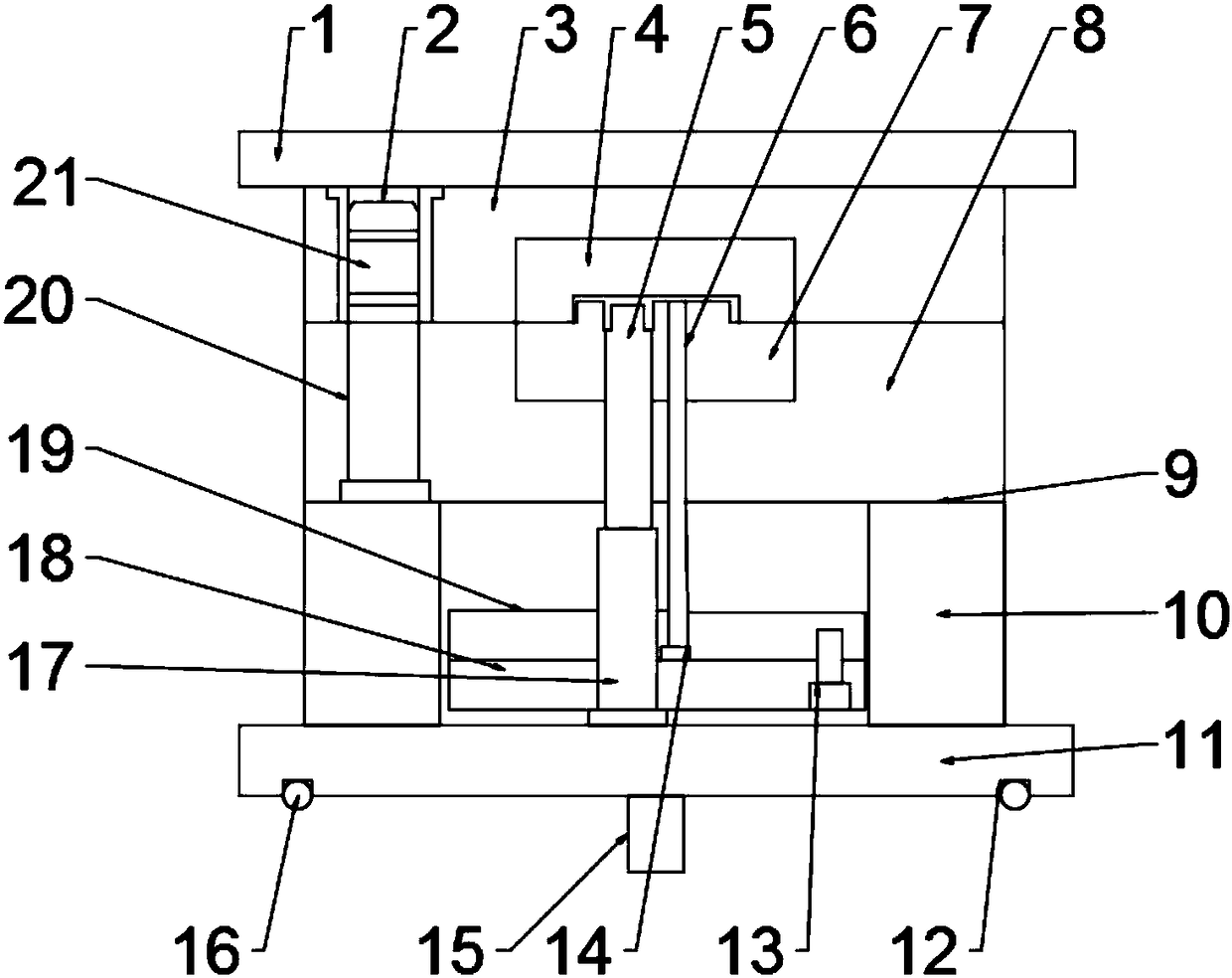

[0013] see figure 1 , a multi-adjustable plastic mould, comprising an upper mold 3 and a lower mold 9, an upper mold core 4 and a lower mold core 7 are respectively provided between the upper mold 3 and the lower mold 9, and an upper mold core 7 is arranged between the lower mold 9 A floating core 5 is arranged on the top, and the upper end of the floating core 5 is set in the lower mold core 7, and a jacking assembly 14 capable of ejecting the product is provided on the lower mold 9; the upper mold 3 and the lower mold 9 A guide device 20 is provided between them; wherein the guide device 20 includes a guide post 21 arranged on the lower die 9, a guide sleeve 2 is provided on the upper die 3, and the guide post 21 is arranged on the guide post 21. In the cover 2; the lower mold 9 includes a lower mold base 8, the lower mold kernel 7 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com