Lateral current collection section insulator

A segmented insulator, side technology, applied in the direction of overhead lines, power rails, etc., can solve the loss of segmental insulation function of segmental insulators, without considering the height difference of segmental insulators, and without considering segmental insulation The problem of self-cleaning function of the appliance can be solved, and the effect of inhibiting the deposition of dirt and reducing the workload of daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

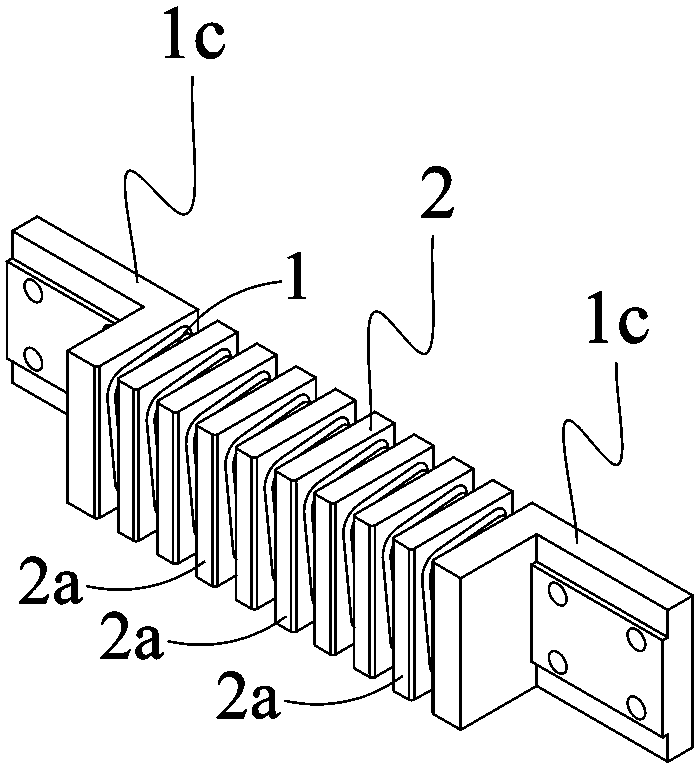

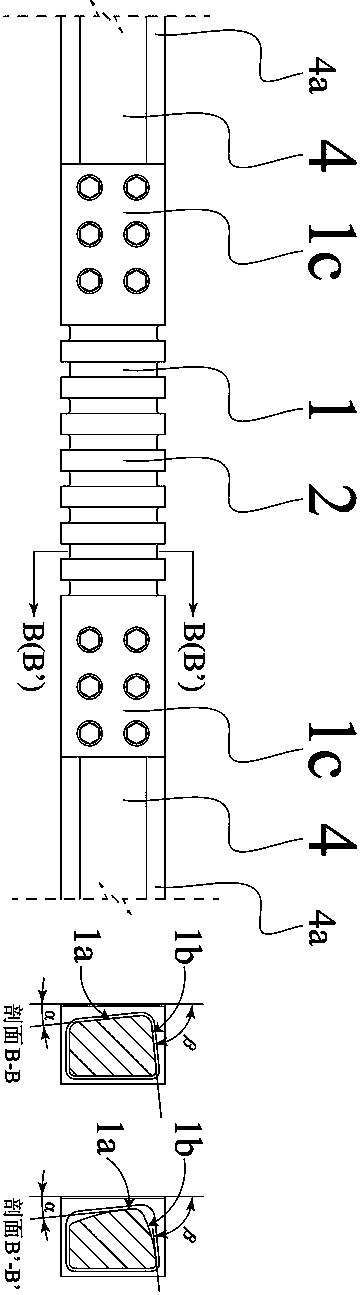

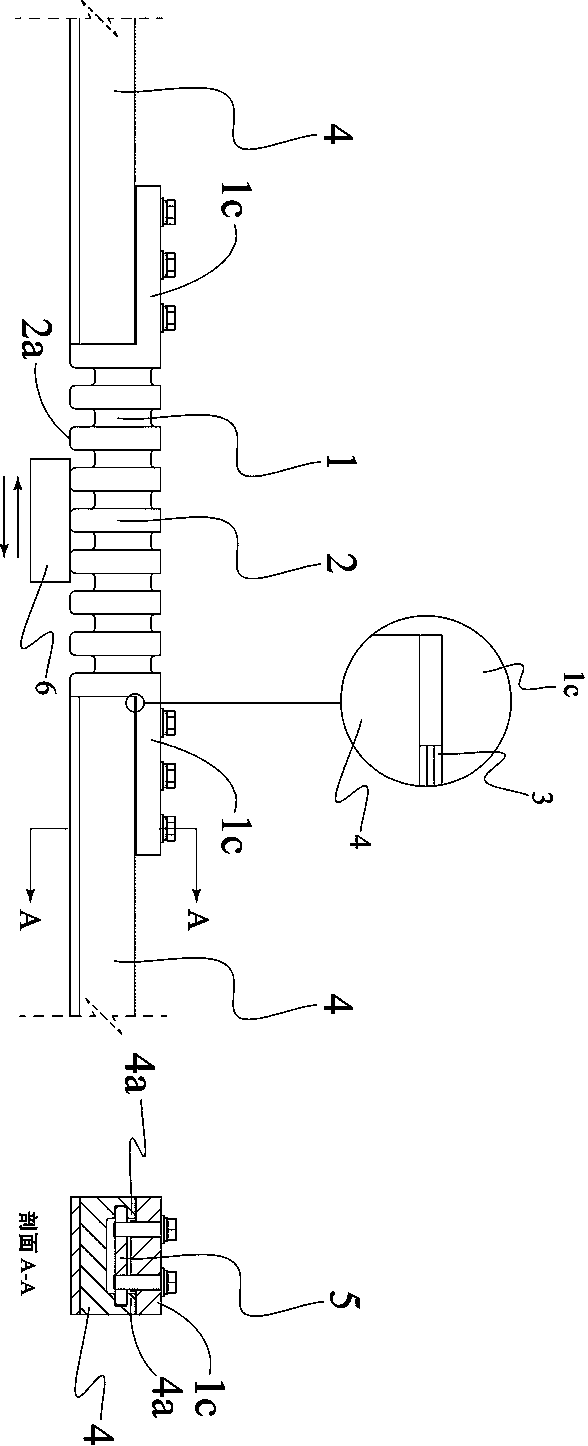

[0015] Figure 1 to Figure 3 It shows a side current receiving section insulator described in this application, which includes an insulating body (1), a shed (2), and the shed (2) is arranged on the insulating body (1) and slides along the brush Direction distribution, the edge of the shed (2) is chamfered, the insulating body (1) has a side surface (1a), a top surface (1b), and the acute angle (α, β) between it and the friction surface (2a) They are 0 figure 2 shown).

[0016] The surface of the section insulator is made of hydrophobic wear-resistant material, or further its whole is made of hydrophobic wear-resistant insulating material. The slope / arc surface set in the scheme, combined with its surface hydrophobicity, can effectively inhibit the deposition of dirt on the surface of the segmental insulator under the action of the external environment (vibration, rain, etc.), which is conducive to reducing the daily maintenance workload.

[0017] When the section insulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com