An ultrasonic motor automobile automatic steering system and automobile automatic steering method

An automatic steering system and automatic steering technology, applied in electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve the problem of always grasping the steering wheel, etc., achieve simple structure and manufacturing process, meet the needs of artificial intelligence, and high control precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

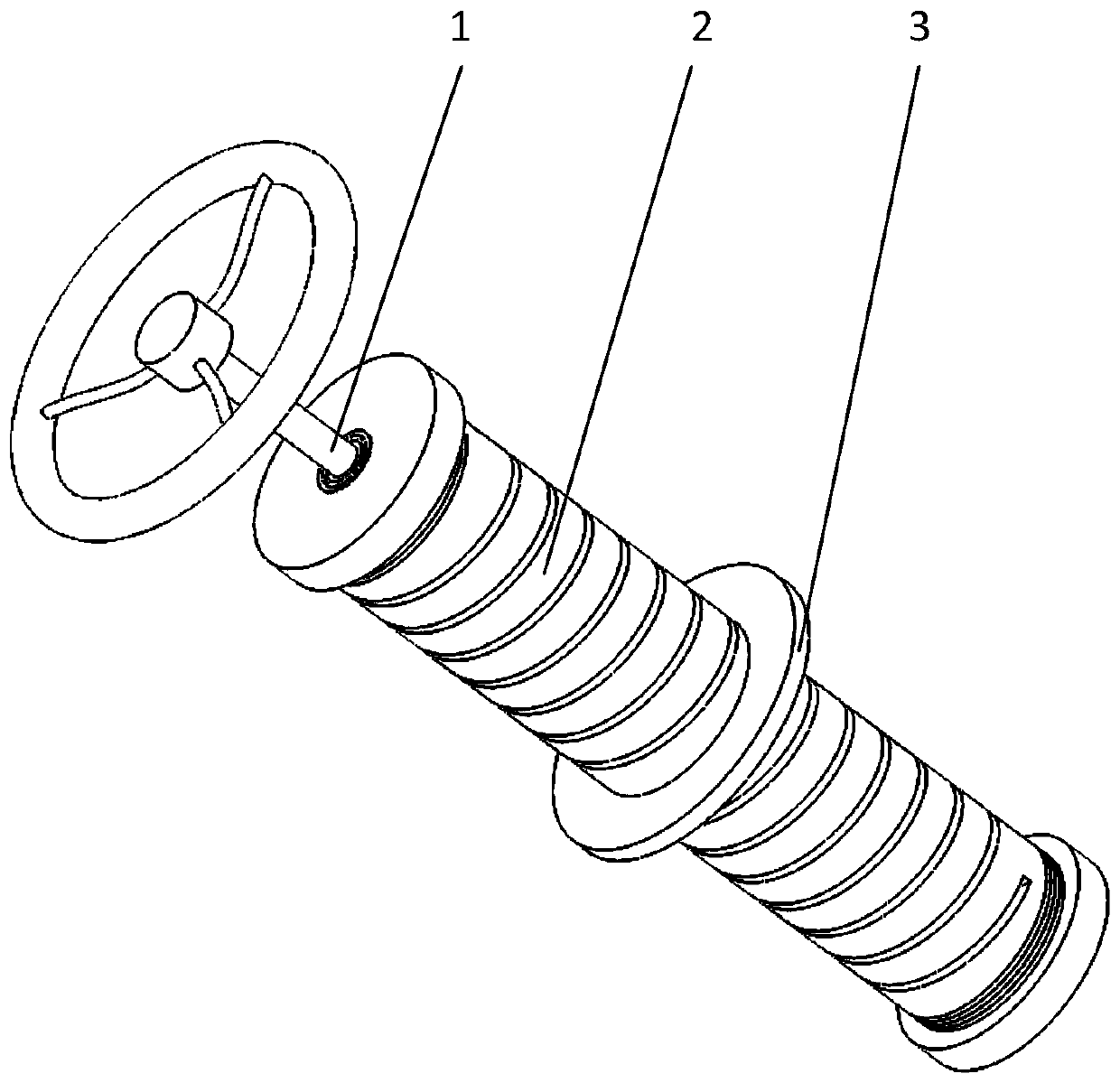

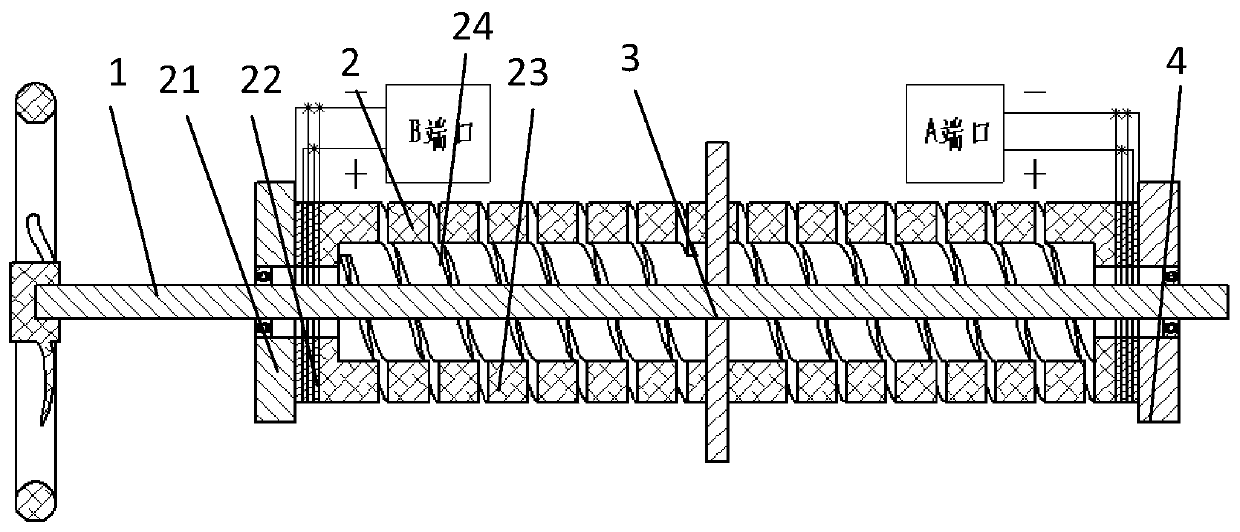

[0038] see Figure 1~2, the ultrasonic motor automobile automatic steering system of the present embodiment comprises a steering rod 1, a flange 3, two 6003 bearings 4, an upper ultrasonic longitudinal torsion motor 2 and a lower ultrasonic longitudinal torsion motor 2, the steering rod 1 is connected with the steering wheel of the automobile, and the Threads are processed on the outer wall of the steering rod 1, and a flange 3 is welded in the middle of the steering rod 1. The flange 3 is a concentric cylindrical structure, and its inner radius is the same as that of the steering rod 1. The inner radius of the 6003 bearing 4 is the same as that of the steering rod. 1 with the same radius. The upper ultrasonic longitudinal torsion motor 2 and the lower ultrasonic longitudinal torsion motor 2 are set on the steering rod 1, distributed on the upper and lower sides of the flange 3 and installed symmetrically with respect to the flange 3, the upper ultrasonic longitudinal torsion ...

Embodiment 2

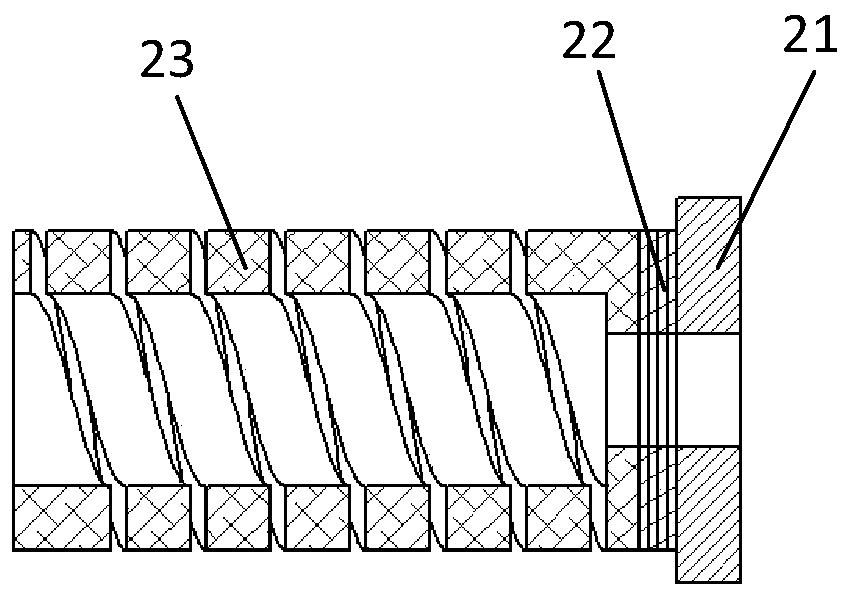

[0054] The slotting cutting body 23 of the ultrasonic longitudinal torsion motor 2 of the present embodiment is provided with two mutually parallel spiral grooves along the circumferential direction on the side wall of a circular tube with one end closed and one end open, and one end of the opening is connected to the flange. The disk 3 is in contact, and one end of the closure is fixed longitudinally with the piezoelectric ceramic stack 22 and the cover plate 21 through a nut, and the cover plate 21 is movably connected to the connecting rod 1 through the bearing 4 in the radial direction; the starting points of the two spiral grooves are on the same circumference, and Evenly distributed on the pipe wall, the round pipe is made of aluminum material, the outer diameter is 100mm, the inner diameter is 60mm, the bottom thickness of the closed end is 10mm, the pipe length is 185mm, the two spiral grooves are left spiral, and the pitch is 50mm, the slot width is 5mm, the helix angl...

Embodiment 3

[0057] Two flanges 3 are respectively welded on the 1 / 3 node and 2 / 3 node of the steering rod 1 of the ultrasonic motor automobile automatic steering system of this embodiment, and ultrasonic vertical torsion plates are installed symmetrically on both sides of the flange 3. Motor 2, that is, three ultrasonic longitudinal and torsion motors 2 are distributed from top to bottom.

[0058] The rotation direction and rotation angle of the ultrasonic longitudinal torsion motor 2 in this embodiment can be determined according to the adjustable voltage output value of the programmable switching power supply module 24 of each ultrasonic longitudinal torsion motor 2. The connection mode and the structure of the ultrasonic warping motor 2 are the same as those of the first embodiment.

[0059] It should be further explained that the helix angle of the slotted cutting body 23 in the above embodiment can be adjusted in the range of 15-45°, and the pitch can be adjusted in the range of 50-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com