Methods for testing and improving interfacial shearing performance of fiber-resin composite under high temperature condition

A resin composite material and fiber resin technology, which is applied in the field of testing the shear performance of the carbon nanotube fiber/epoxy resin composite material interface, has achieved wide application prospects, low cost, and is easy to implement on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

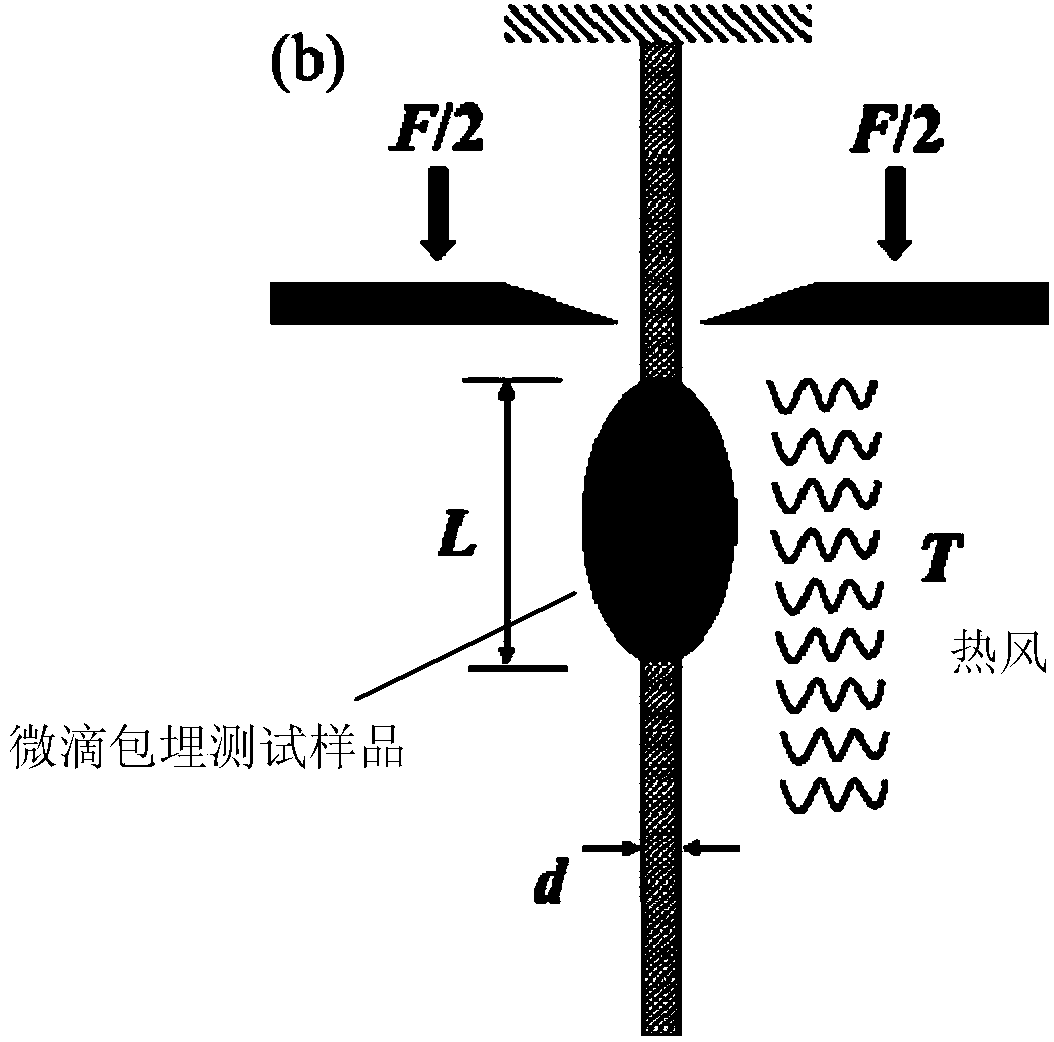

[0057] Embodiment 1 refers to image 3 As shown, the specific operation process of this embodiment is as follows:

[0058] First prepare epoxy resin solution according to the mass ratio of E51 epoxy resin and JH-593 curing agent as 3:1, then dilute the epoxy resin solution with acetone at a mass ratio of 1:1 to form epoxy resin Diluent. Soak the carbon nanotube fiber (same as Comparative Example 1) in the prepared epoxy resin diluent, take it out after fully soaking for 5 minutes, and hang it on both sides of the shelf to dry in the air for 20 minutes, so that the acetone in the fiber can be fully volatilized , thus making carbon nanotube-epoxy composite fibers. Then the undiluted E51 epoxy resin droplets were spotted on the carbon nanotube-epoxy resin composite fibers, and after the resin was cured at 90°C for 1h and at 120°C for 2h, the carbon nanotubes with droplets- The epoxy resin composite fiber was removed to form a sample embedded in microdroplets (hereinafter also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com