Preparation method of double sizing agent modified carbon fiber reinforced epoxy resin matrix composite material

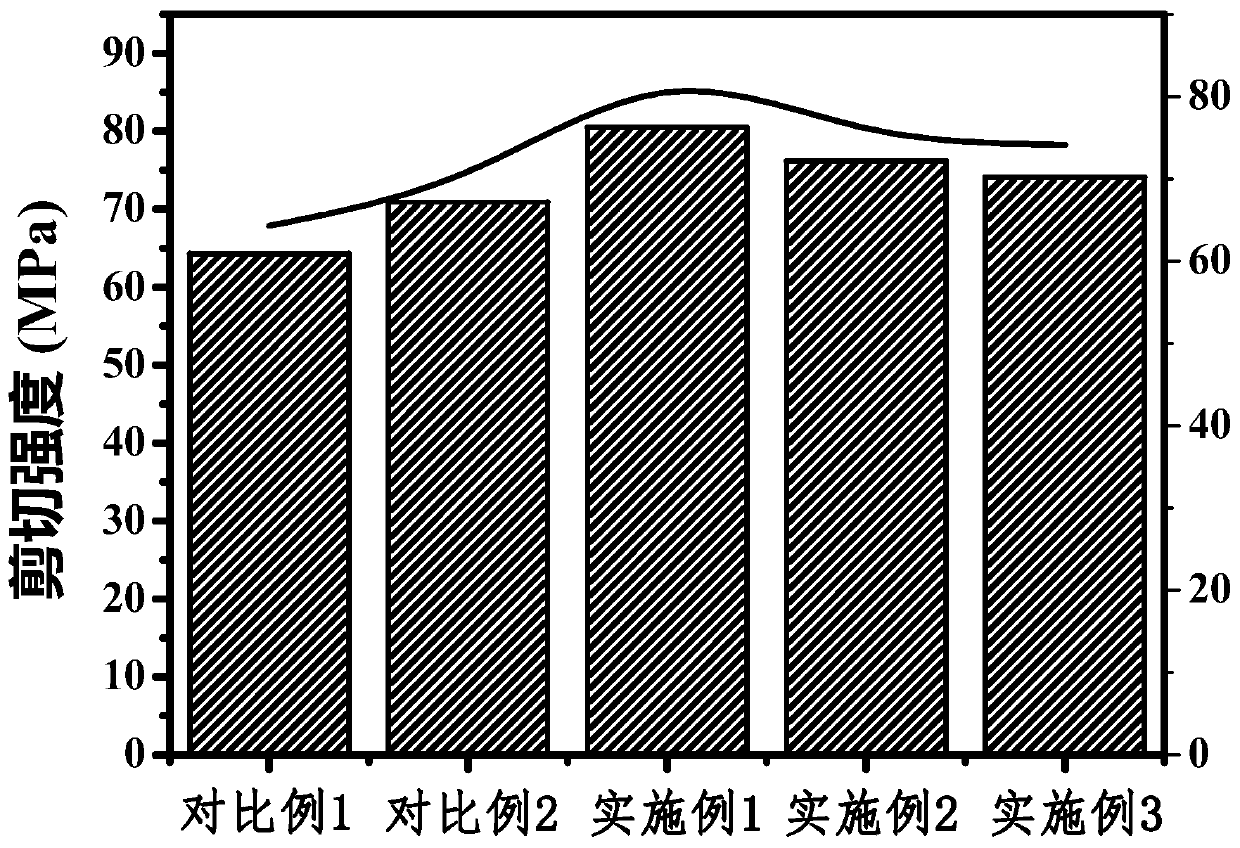

An epoxy resin, fiber reinforced technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve problems such as increased defects, incomplete modification, and little improvement in composite material performance, and achieves improved interfacial shear performance. , the effect of improving tensile properties and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

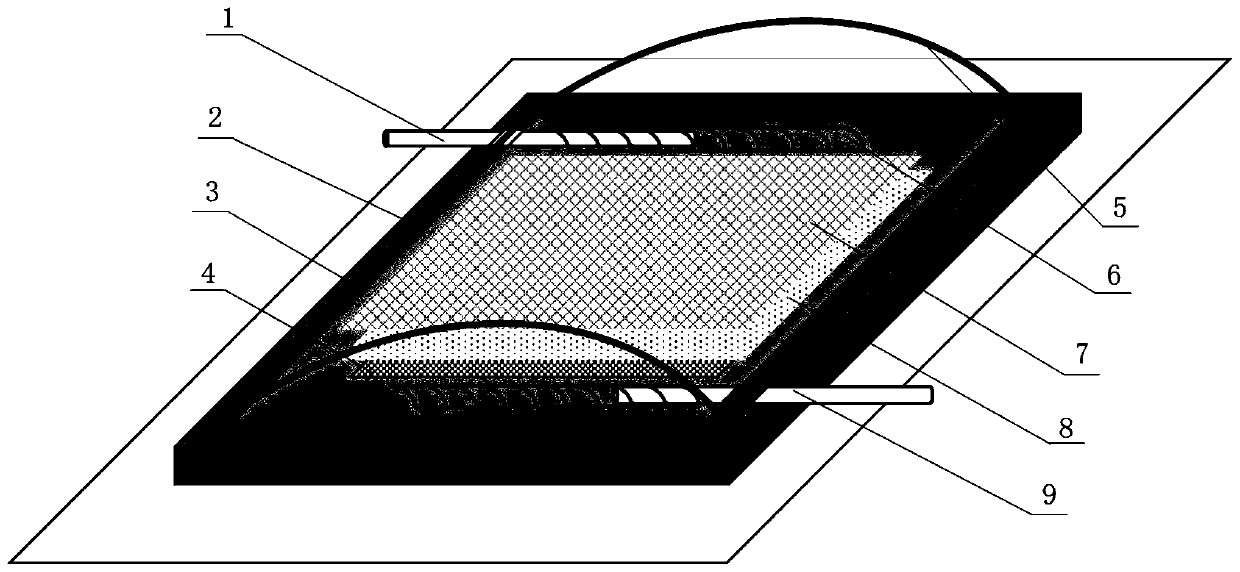

Method used

Image

Examples

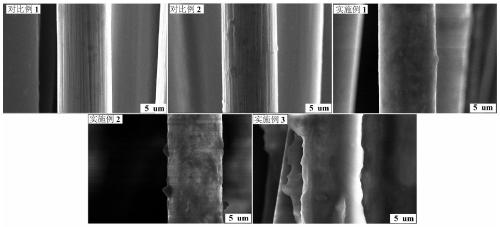

Embodiment 1

[0044] Amino multi-walled carbon nanotubes (CNTs) used in this example were purchased by Beijing Boyu Gaoke New Material Technology Co., Ltd., with a purity of 98%-99.999%; octaaminopropyl polyhedral oligomeric silsesquioxane (OA- POSS) is provided by the School of Chemical Engineering, Hebei University of Technology, with a purity of 97%-99.988%; tetraethyl orthosilicate (TEOS) concentration is more than 95%, ethanol (C 2 h 5 OH) concentration is 70%-90%, ammonia water (NH 3 OH) concentration is 70%-80%, and the above basic chemical materials are all pure substances for chemical analysis. The carbon fiber cloth is T300.

[0045] The steps of the preparation method of the double sizing agent modified carbon fiber reinforced epoxy resin-based composite material in this embodiment are:

[0046] 1) Preparation of carbon nanotube modified solution: dissolving silane coupling agent in ethanol solution, stirring at a speed of 1000r / min to obtain silane coupling agent sol; then si...

Embodiment 2

[0054]The steps for preparing the modified carbon fiber reinforced epoxy resin-based composite material in this example are the same as in Example 1, except that the mass percentage of each substance in the carbon nanotube modification solution described in this example is: 0.5% silane Joint agent sol, 1.0% amino multi-walled carbon nanotubes, 98.5% dispersant.

Embodiment 3

[0056] The steps of modifying the carbon fiber reinforced epoxy resin-based composite material in this example are the same as in Example 1, except that the mass percentage of each substance in the carbon nanotube modification solution described in this example is: 0.5% silane coupling Solvent sol, 2.0% amino multi-walled carbon nanotubes, 97.5% dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com