Method for preparing three-phase bismaleimide resin matrix composite material, and applications of three-phase bismaleimide resin matrix composite material

A technology of maleimide resin and chemical grafting, which is applied in the field of preparation of three-phase bismaleimide resin-based composite materials, can solve problems such as unattainable mechanical properties, achieve excellent mechanical and mechanical properties, improve impact performance, the effect of alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is a method for preparing a three-phase bismaleimide resin-based composite material by chemical grafting of carbon fiber-carbon nanotube micro-nano synergistically reinforced phase, which is carried out according to the following steps:

[0035] (1) Surface oxidation of CNT: Prepare 100ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 as a strong oxidant, weigh 1g of CNT and add it to the pre-prepared mixed acid solution and disperse it with an ultrasonic wave with a frequency of 80KHz for 20min . Stir it magnetically in a water bath at 60°C for 2 hours until uniform, then filter the reaction solution on a polytetrafluoroethylene microporous filter membrane with a pore size of 0.45 μm, and repeatedly wash with deionized water until the filtrate is neutral to obtain CNT -COOH;

[0036] (2) Preparation of CNT-PEI: disperse the treated carbon nanotubes into 100ml of water with an ultrasonic frequen...

Embodiment 2

[0046] This embodiment is a method for preparing a three-phase bismaleimide resin-based composite material by chemical grafting of carbon fiber-carbon nanotube micro-nano synergistically reinforced phase, which is carried out according to the following steps:

[0047] (1) Surface oxidation of CNT: Prepare 100ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 as a strong oxidant, weigh 1g of CNT and add it to the pre-prepared mixed acid solution and disperse it with an ultrasonic wave with a frequency of 80KHz for 20min . Stir it magnetically in a water bath at 60°C for 2 hours until uniform, then filter the reaction solution on a polytetrafluoroethylene microporous filter membrane with a pore size of 0.45 μm, and repeatedly wash with deionized water until the filtrate is neutral to obtain CNT -COOH;

[0048] (2) Preparation of CNT-PEI: disperse the treated carbon nanotubes into 100ml of water with an ultrasonic frequen...

Embodiment 3

[0058] This embodiment is a method for preparing a three-phase bismaleimide resin-based composite material by chemical grafting of carbon fiber-carbon nanotube micro-nano synergistically reinforced phase, which is carried out according to the following steps:

[0059] (1) Surface oxidation of CNT: Prepare 100ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 as a strong oxidant, weigh 1g of CNT and add it to the pre-prepared mixed acid solution and disperse it with an ultrasonic wave with a frequency of 80KHz for 20min . Stir it magnetically in a water bath at 60°C for 2 hours until uniform, then filter the reaction solution on a polytetrafluoroethylene microporous filter membrane with a pore size of 0.45 μm, and repeatedly wash with deionized water until the filtrate is neutral to obtain CNT -COOH;

[0060] (2) Preparation of CNT-PEI: disperse the treated carbon nanotubes into 100ml of water with an ultrasonic frequen...

PUM

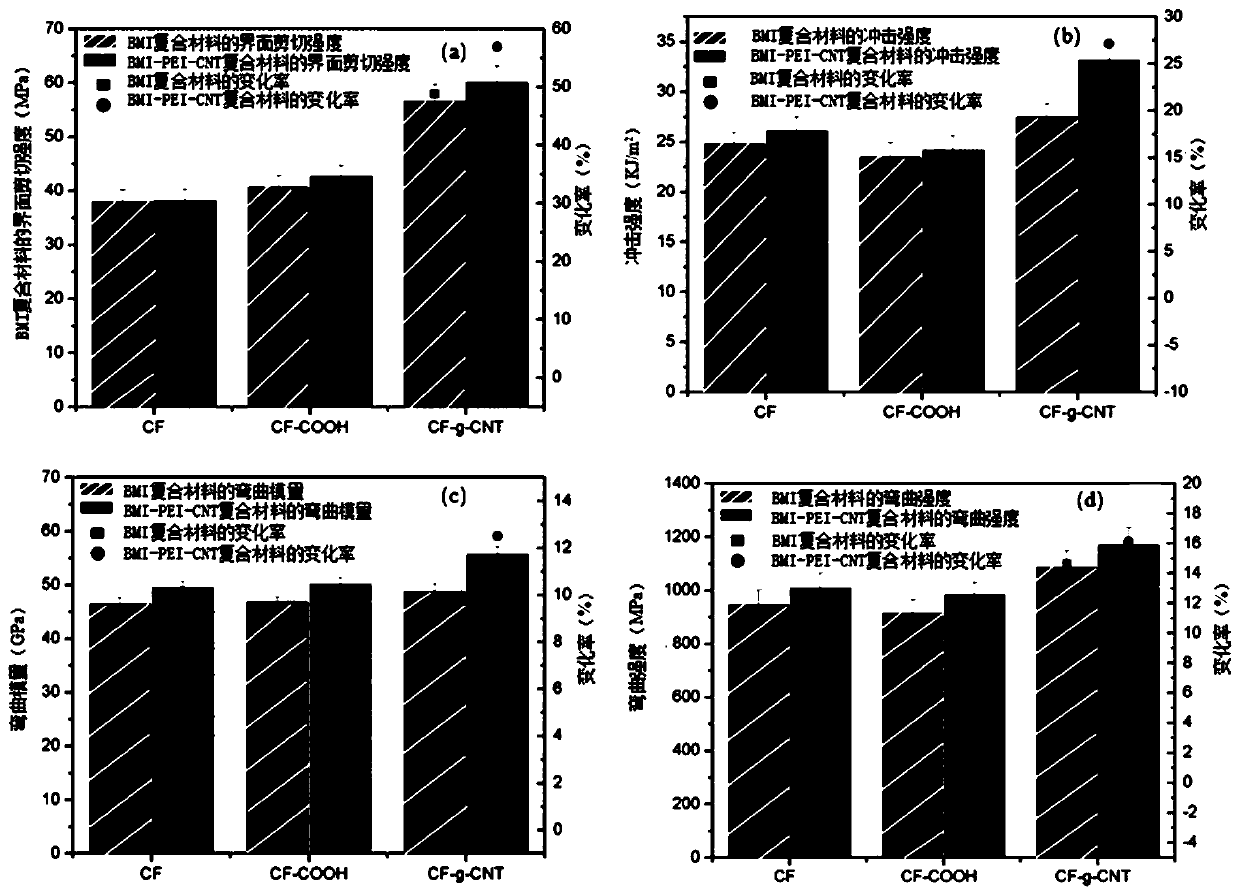

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com