A cooling water tank of a passive containment cooling system

A passive containment and cooling system technology, applied in the field of cooling water tanks, can solve the problems of rising inlet coolant temperature and falling cooling power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

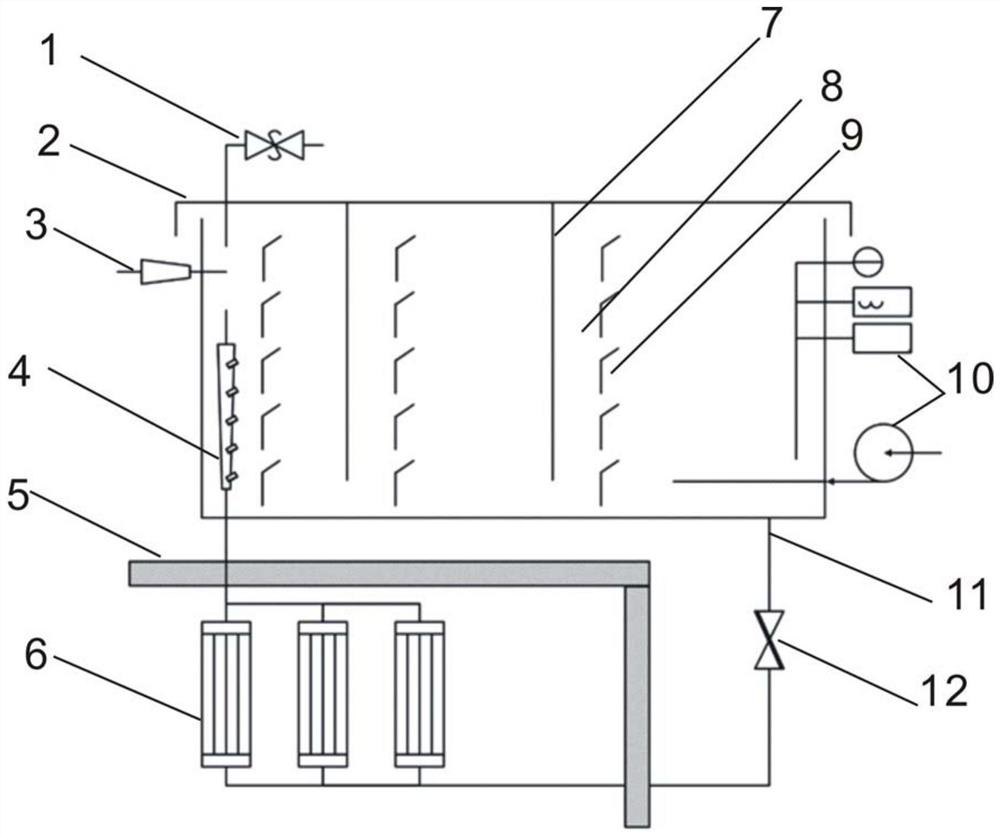

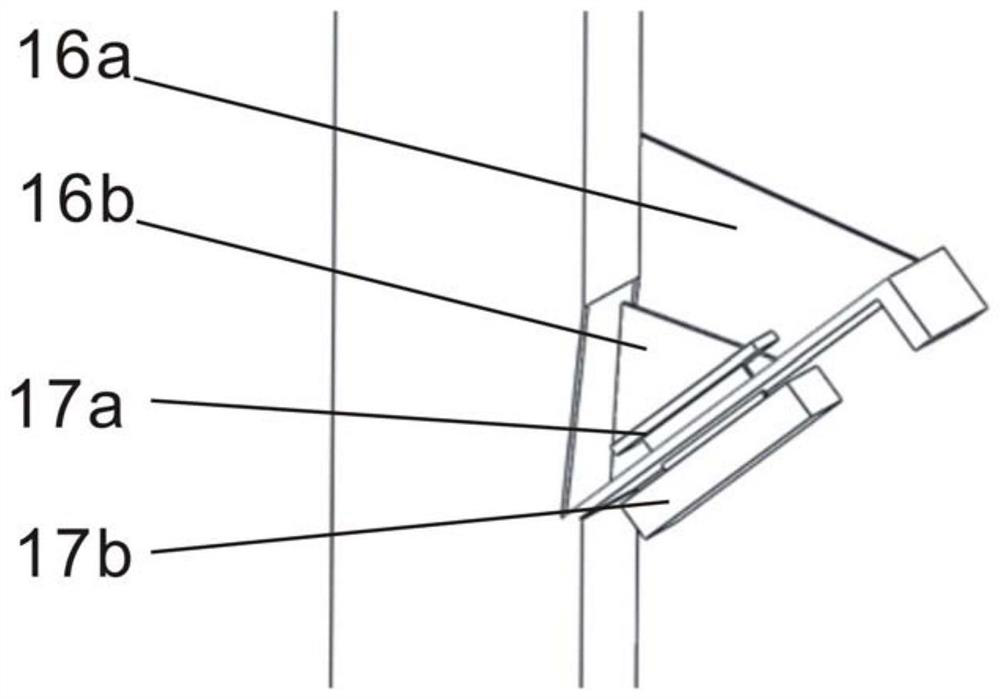

[0031]The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0032]In view of the shortcomings of the cooling water tank in the prior art, the inventors deepen the research and improvement of prior art, thereby causing the cooling system to return to the hot water of the large water pool to avoid being blended directly with the main water body, maximizing the overall water temperature rise. High, especially the maximum level of maintenance of the low water temperature of the inlet of the circulating cooling system, and the maximum level is maintained at a higher level, so that the safety shell temperature and pressure are faster to a more secure state and have been maintained.

[0033]The cooling tank design of the non-energy safety shell cooling system provided by the present invention applies thermal management idea, and manages the recovered high temperature coolant partition, which maximizes the low temperature coolant for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com