Coil winding and assembling integrated machine

An integrated machine and coil technology, applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of excessive labor, inconvenience and disadvantage in the production and assembly of vibration motor coils, and achieve the effect of reducing labor costs and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

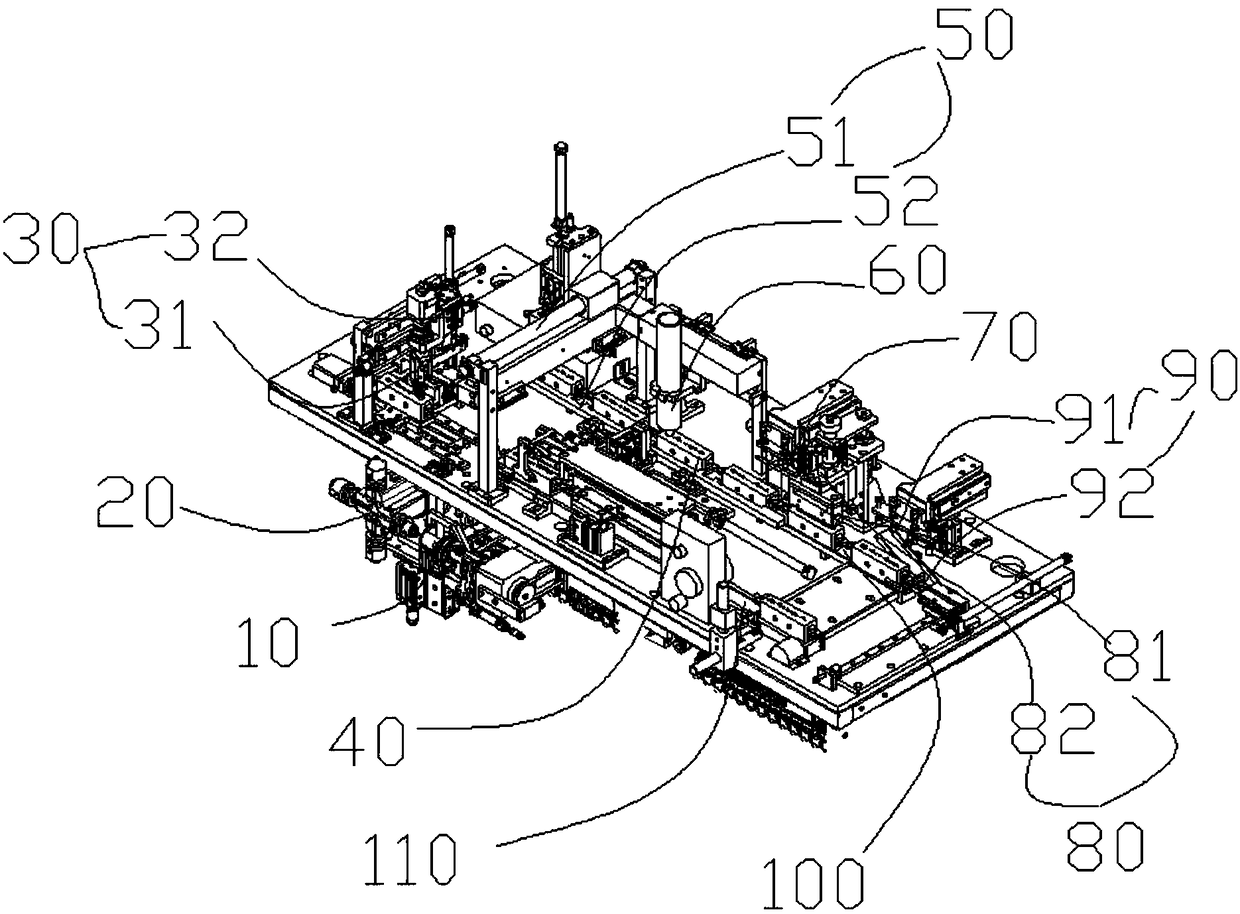

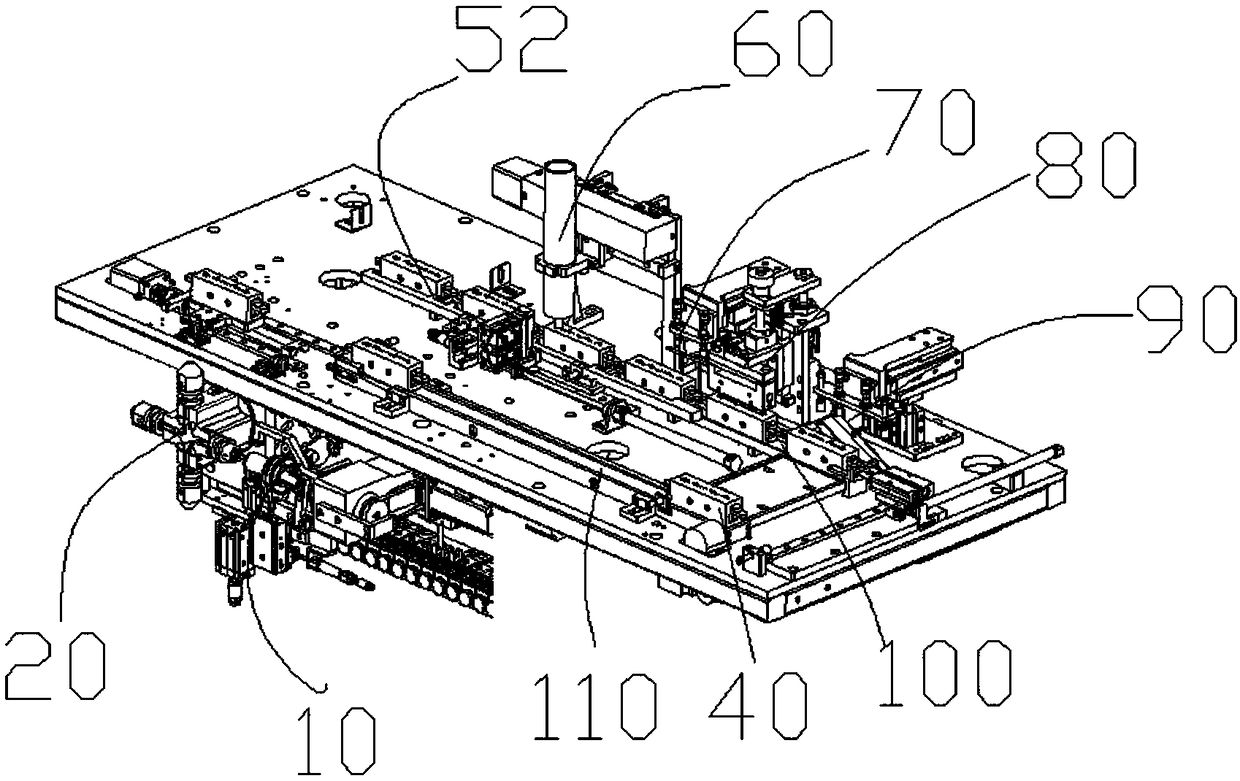

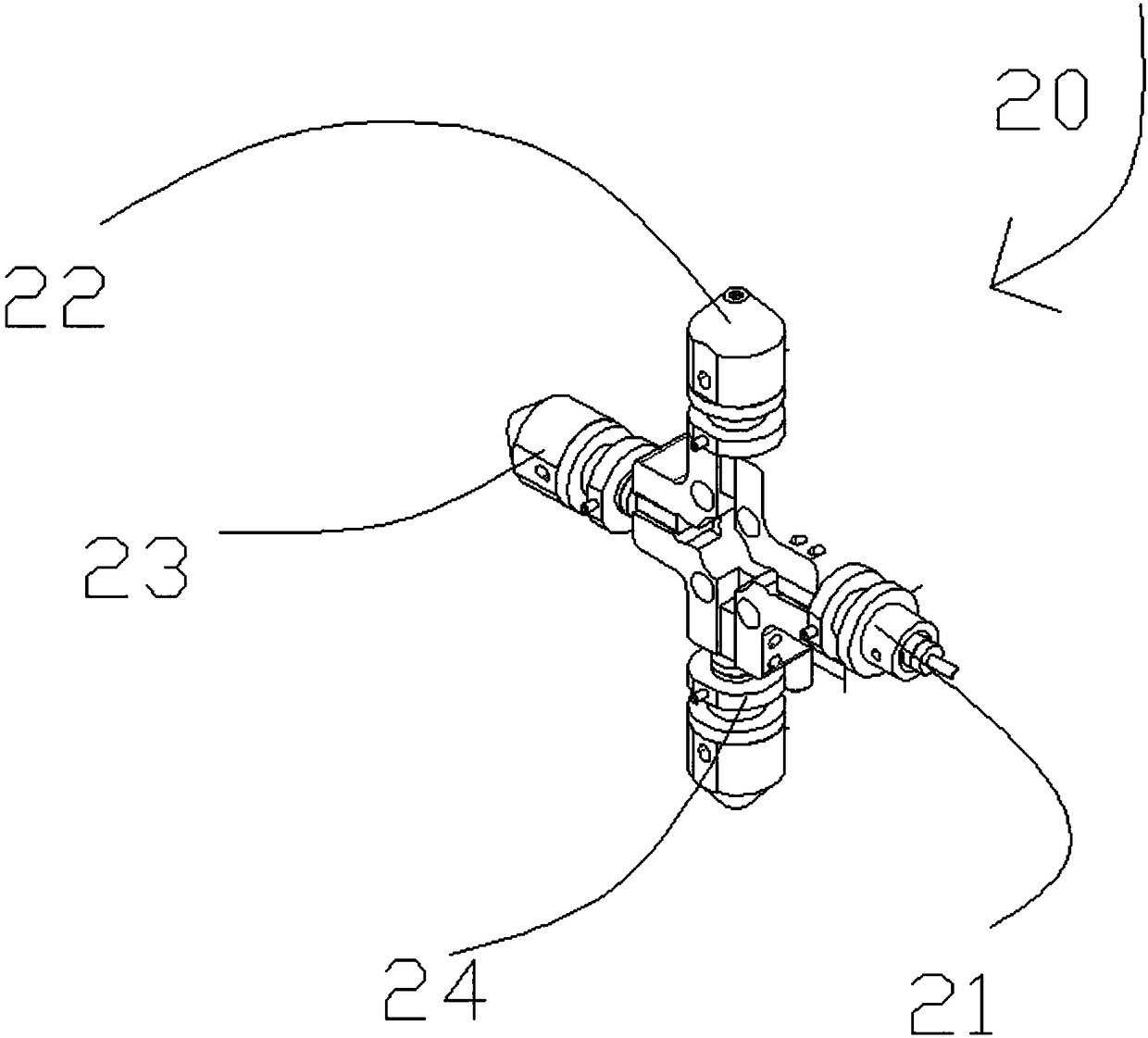

[0026] Please refer to Figure 1-Figure 3 , the coil winding and assembling machine includes a winding device 10, a wire storage device 20, a wire clamping device 30, a jig plate 40, a feeding device 50, a dispensing device 60, a PCB assembly device 70, and a hot-press drying device 80 , the blanking device 90, the first rail 100 and the second rail 110, the wire storage device 20 includes a first wire storage part 21, a second wire storage part 22, a third wire storage part 23, and a fourth wire storage part 24 , the clamping device 30 includes a telescopic device 31 and a steering head 32, the feeding device includes a first pushing device 51 and a second pushing device 52, and the PCB assembly device 70 includes a hanging column 72 and a first suction part 71, The hot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com