Bottom irradiating type high temperature and high pressure photochemical reaction kettle

A photochemical reaction, high temperature and high pressure technology, applied in the direction of pressure vessels used in chemical processes, chemical/physical/physicochemical processes that apply energy, etc., can solve the problem of not setting a light source, not giving an implementation method, and frequently switching on and off the protective box problems such as doors, to enhance the photocatalytic effect, reduce outward scattering, and avoid light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

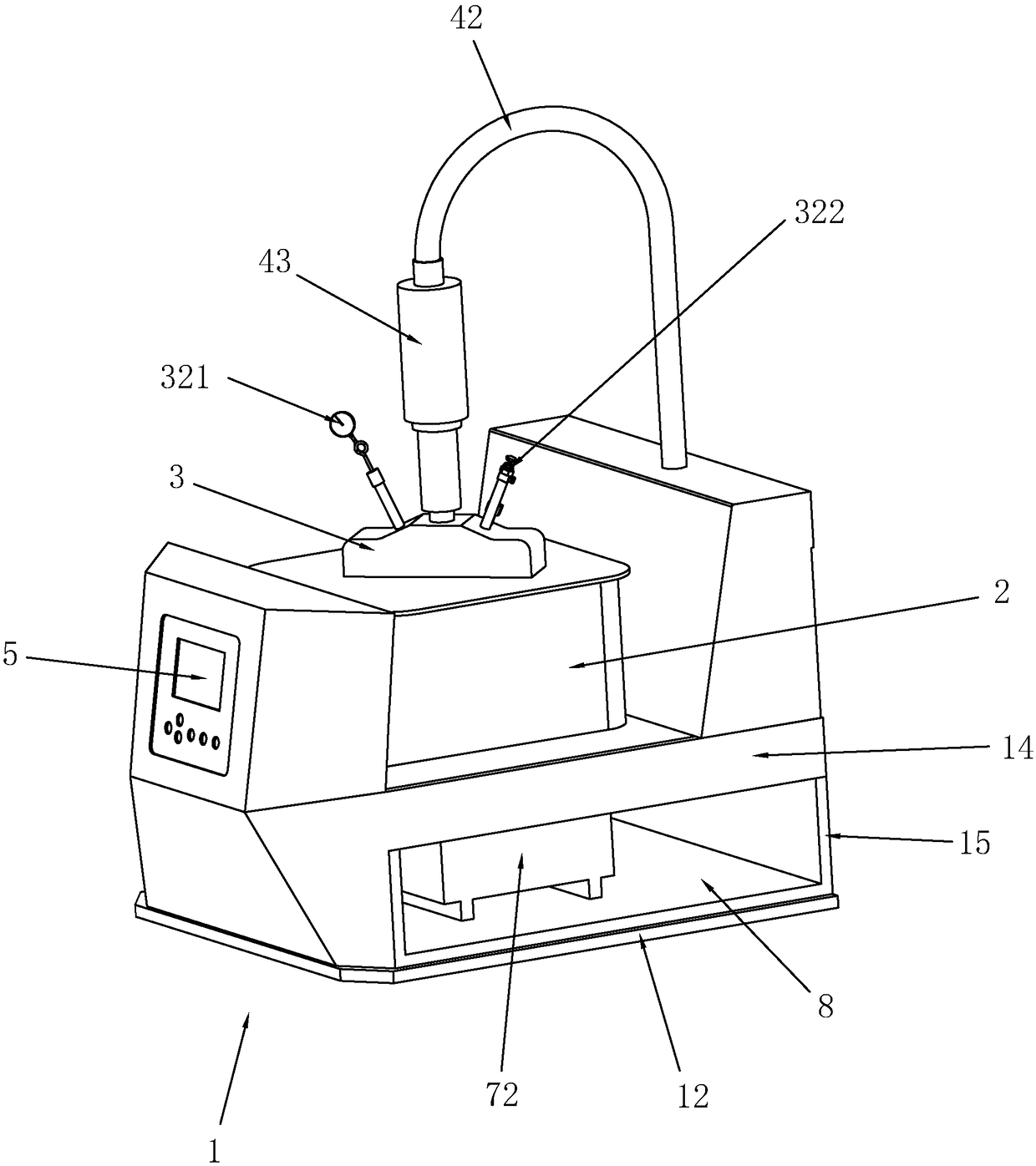

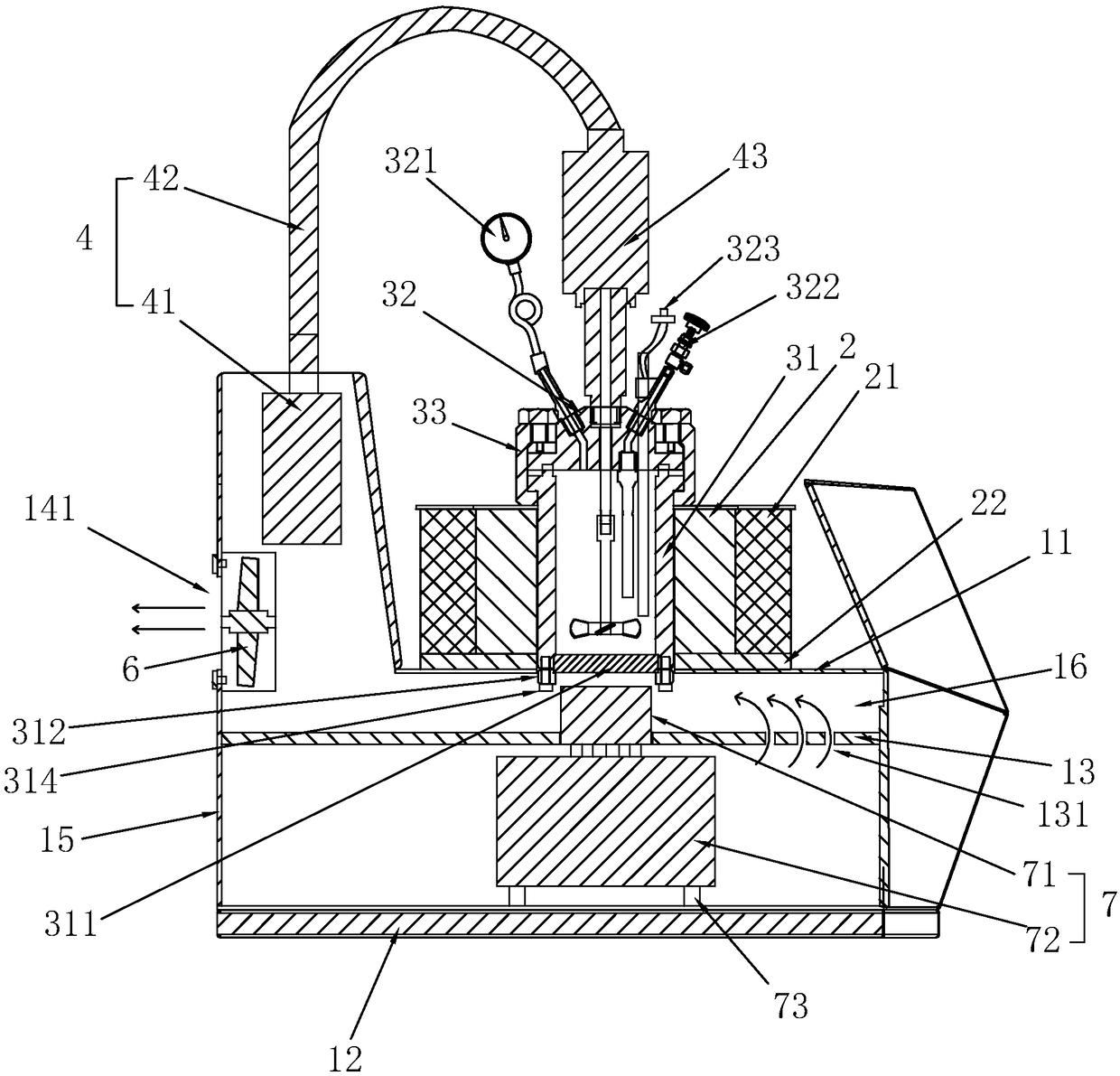

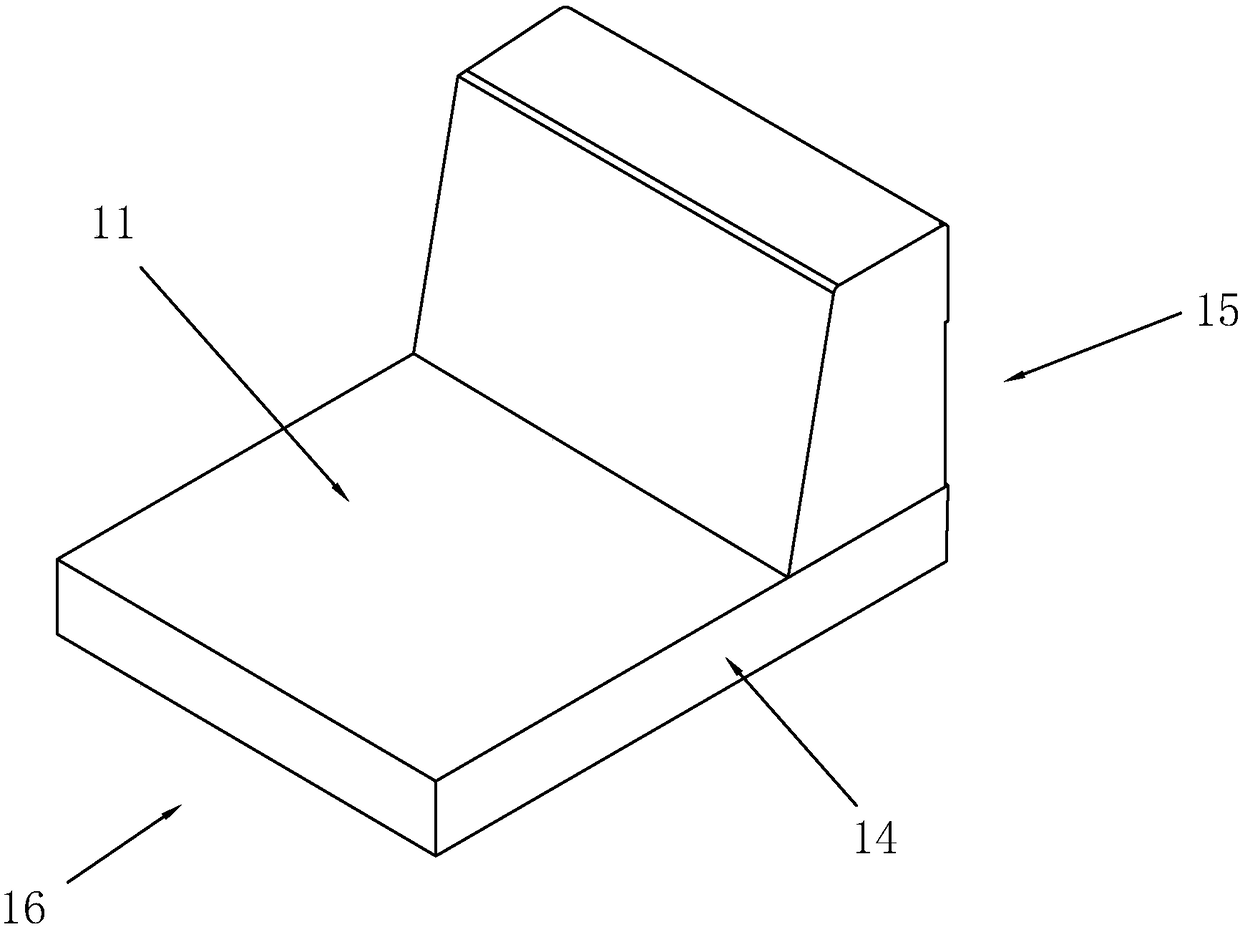

[0047] Embodiment 1: A kind of bottom-illuminated high-temperature and high-pressure photochemical reactor, such as figure 1 and figure 2As shown, a cabinet 1 is included, a heating furnace 2 is arranged on the cabinet 1, and a reaction kettle 3 is placed in the middle of the heating furnace 2, and the internal reaction kettle 3 is heated by the heating furnace 2. The side wall of the heating furnace 2 is provided with a circle of insulation layer 21, which can play the effect of insulation. A stirring assembly 4 for stirring in the reaction kettle 3 is installed on the cabinet 1, including a driving motor 41 located in the cabinet 1 and a driving flexible shaft 42 connected to the driving motor 41, and one end of the driving flexible shaft 42 is connected with a magnetic coupling stirrer 43. The magnetically coupled stirrer 43 extends downward into the reactor 3 for stirring. The cabinet 1 is also provided with a controller 5 for program controlling the components of the r...

Embodiment 2

[0055] Embodiment 2: A bottom-illuminated high-temperature and high-pressure photochemical reactor, the difference from Embodiment 1 is that, as Figure 5 As shown, the inner wall of the sapphire flange 312 is pasted with a reflective lens 3121, and the lamp holder 72 (see figure 2 ) when the light emitted obliquely on the inner wall of the sapphire flange 312 can be reflected by the reflective lens 3121 to the sapphire sheet 311, so as to enter the kettle body 31 through the sapphire sheet 311, further enhancing the effect of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com