Pre-forming mold for polygonal multi-layer fabric composite material pipe

A multi-layer fabric and composite material technology, which is applied to home appliances, tubular objects, and other home appliances, can solve the problems of low transverse strength, poor lap joints, and increased thickness of products, and achieve stable product quality, good lap joints, Guaranteed the effect of lateral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

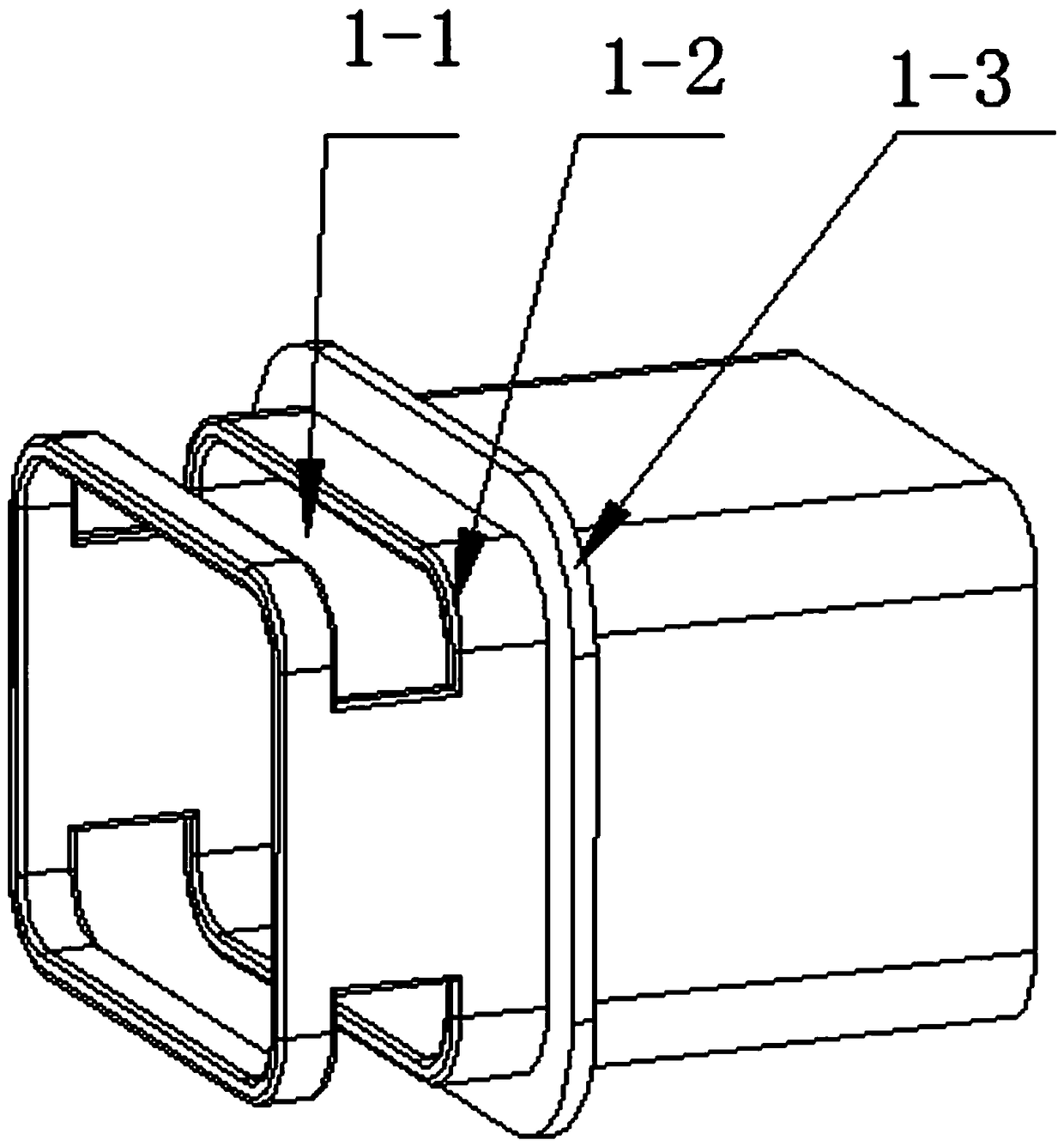

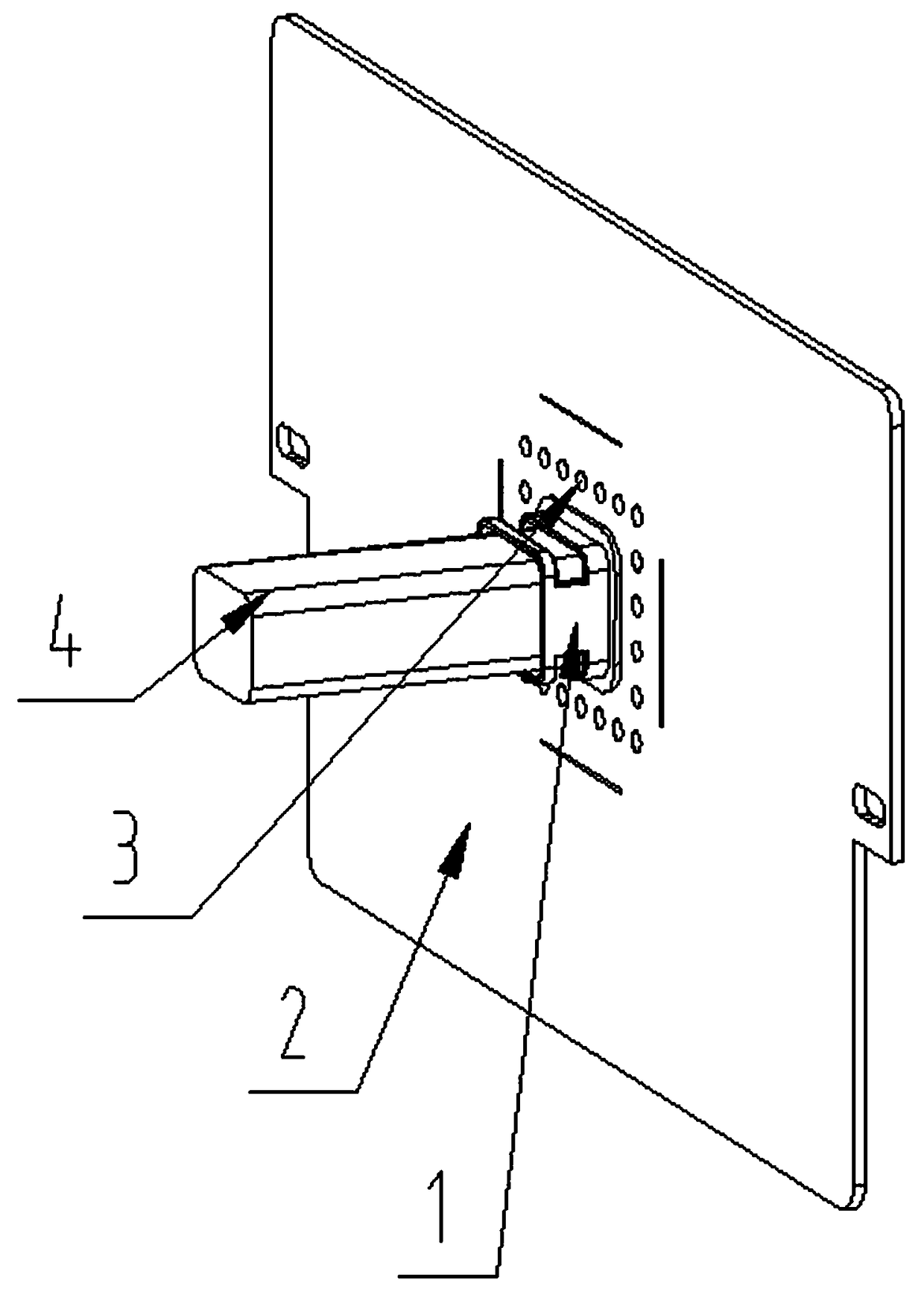

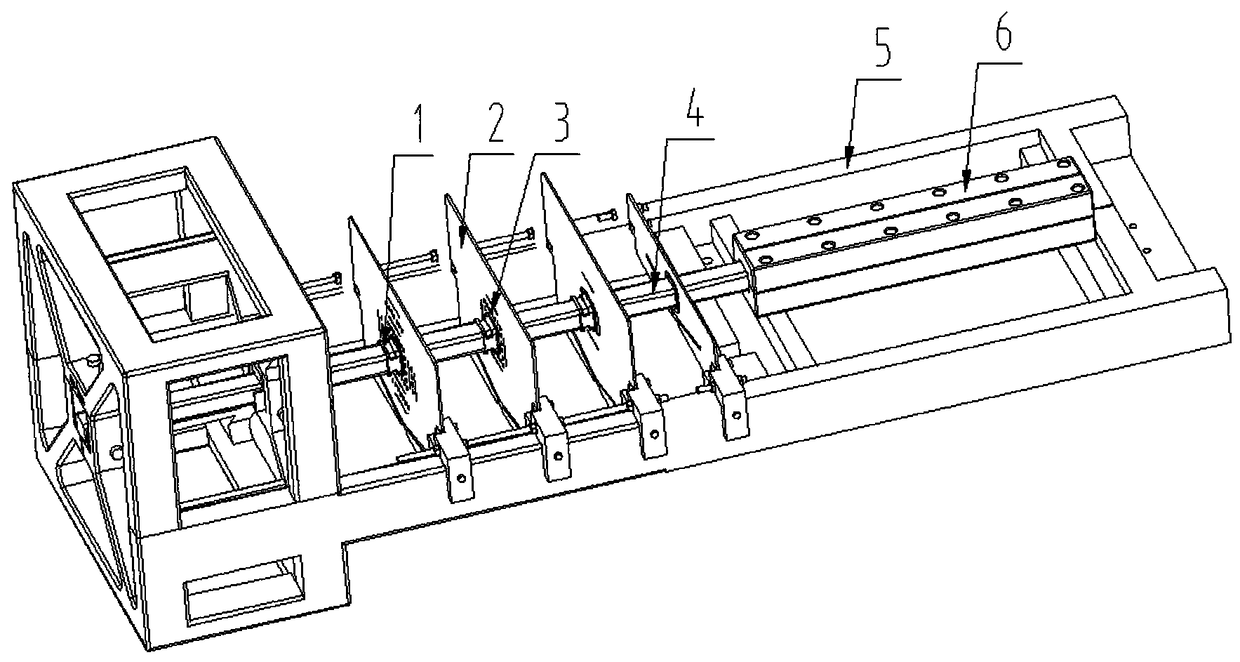

[0017] Such as Figure 1-4 As shown, the present invention is a polygonal multi-layer fabric composite material pipe preforming mold, and square holes 1-1 are processed at intervals on the preforming mold 1, and the square holes 1-1 extend to the circular arc 1 on the adjacent surface At -2, the square holes on the preforming mold should be processed at intervals, that is, the adjacent surfaces do not process square holes, and the interval surfaces process square holes; figure 1 As shown, a square hole 1-1 is processed on the upper and lower sides of the preforming mold 1 and extends to the circular arcs 1-2 on both sides, and the square holes are not processed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com