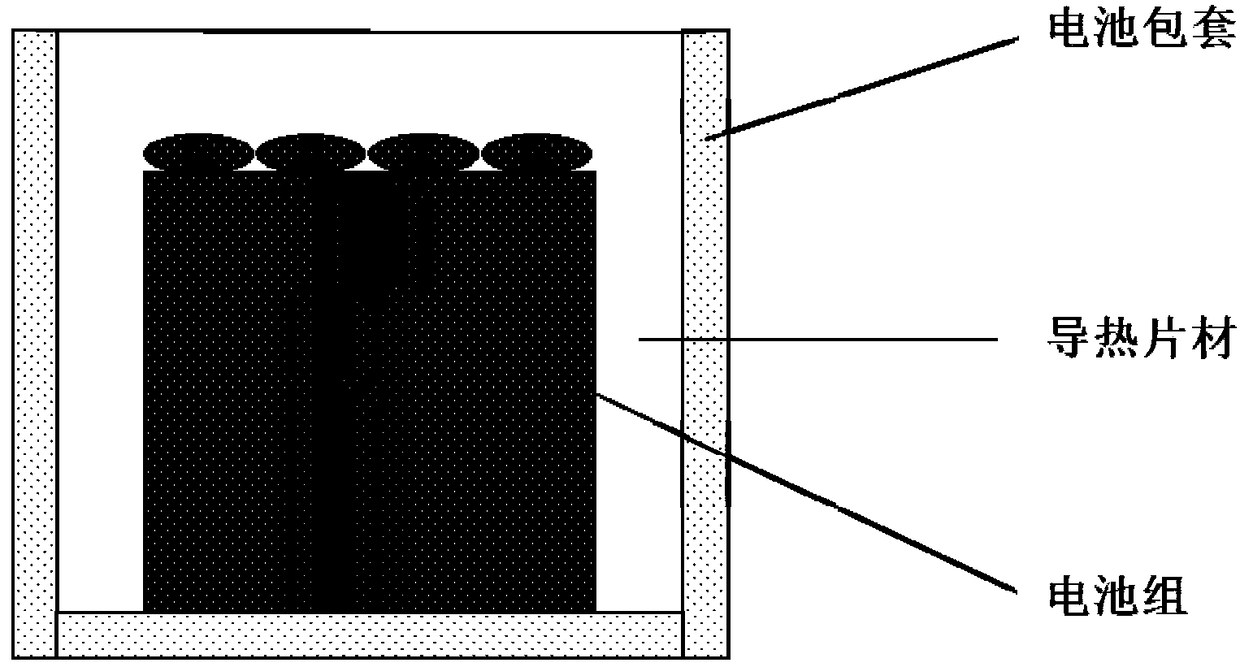

Lightweighting heat-conductive sheet material, and preparation method and applications thereof

A thermally conductive sheet and lightweight technology, which is applied to the lightweight thermally conductive sheet and its preparation and application fields, can solve the problems of fogging on the mirror surface of LEDs and automobile lampshades, failure of screen printing ink adhesion, failure of electrical connection points, etc. Oil phenomenon and fogging phenomenon, high thermal conductivity and mechanical properties, effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

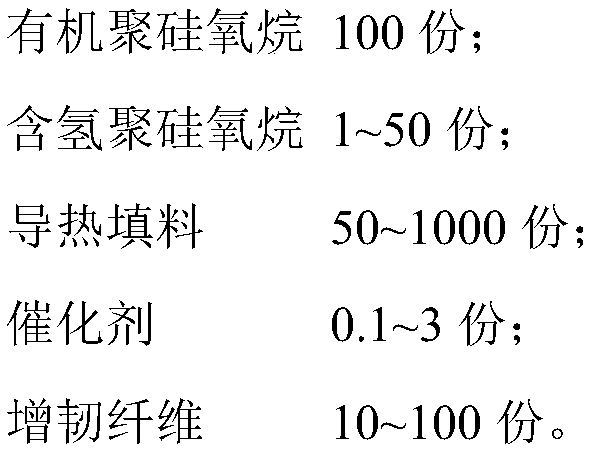

[0034] The preparation method of this lightweight heat-conducting sheet comprises the following steps:

[0035] 1) take raw material by weighing above-mentioned composition;

[0036] 2) Heat and knead organopolysiloxane, hydrogen-containing polysiloxane, thermally conductive filler and toughening fiber under vacuum, add catalyst after cooling, and continue vacuum mixing to obtain a semi-finished product;

[0037] 3) Press the semi-finished product into tablets, and then vulcanize and form it to obtain a lightweight heat-conducting sheet.

[0038] Preferably, in step 2) of the preparation method, the thermally conductive filler is dried before use; further, when the thermally conductive filler is a nano-filler, the surface is treated with a silane coupling agent after drying.

[0039] Preferably, in step 2) of the preparation method, the degree of vacuum is ≤0.01 MPa; the heating temperature is 40°C-180°C.

[0040] Preferably, in the step 2) of the preparation method, the mix...

Embodiment 1

[0049] The lightweight thermally conductive sheet of Example 1 consists of the following raw materials in parts by mass:

[0050]

[0051] The organopolysiloxane used is a vinyl-containing organopolysiloxane, which can be divinyl polydimethylsiloxane; the hydrogen-containing silicone oil is methyl hydrogen-containing silicone oil; the platinum catalyst is a platinum catalyst; the toughening The fibers are chopped glass fibers with a diameter of 9 μm to 13 μm and a length of less than 20 mm.

[0052] Before use, pretreat the nano-zinc oxide, dilute it with KH550 silane coupling agent according to 1:20 alcohol, spray it on the surface of nano-zinc oxide, and dry it in an oven at 80°C for 2 hours. Flake boron nitride and hollow glass microspheres were dried in an oven at 100°C for 2 hours.

[0053] Put organopolysiloxane, hydrogen-containing silicone oil, nano-zinc oxide, flake boron nitride, and hollow glass microspheres into a vacuum kneader, mix at 150°C for 1 hour, and ma...

Embodiment 2

[0056] The lightweight thermally conductive sheet of Example 2 consists of the following raw materials in parts by mass:

[0057]

[0058] The organopolysiloxane used is a vinyl-containing organopolysiloxane, which can be divinyl polydimethylsiloxane; the hydrogen-containing silicone oil is methyl hydrogen-containing silicone oil; the platinum catalyst is a platinum catalyst; the toughening The fibers are chopped carbon fibers with a diameter of 5 μm to 8 μm.

[0059] Before use, pretreat the nano aluminum hydroxide, dilute it with KH550 silane coupling agent according to 1:20 alcohol, spray it on the surface of nano zinc oxide, and dry it in an oven at 80°C for 2 hours. Graphite oxide and hollow glass microspheres were dried in an oven at 100°C for 2 hours.

[0060] Put organopolysiloxane, hydrogen-containing silicone oil, nano-zinc hydroxide, graphite oxide, and hollow glass microspheres into a vacuum kneader, mix at 160°C for 1 hour, and maintain a vacuum degree of ≤0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com