Sensor

A sensor and strain gauge technology, applied in the sensor field, can solve the problem that the sensor cannot measure the braking force and gravity of the motor vehicle at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

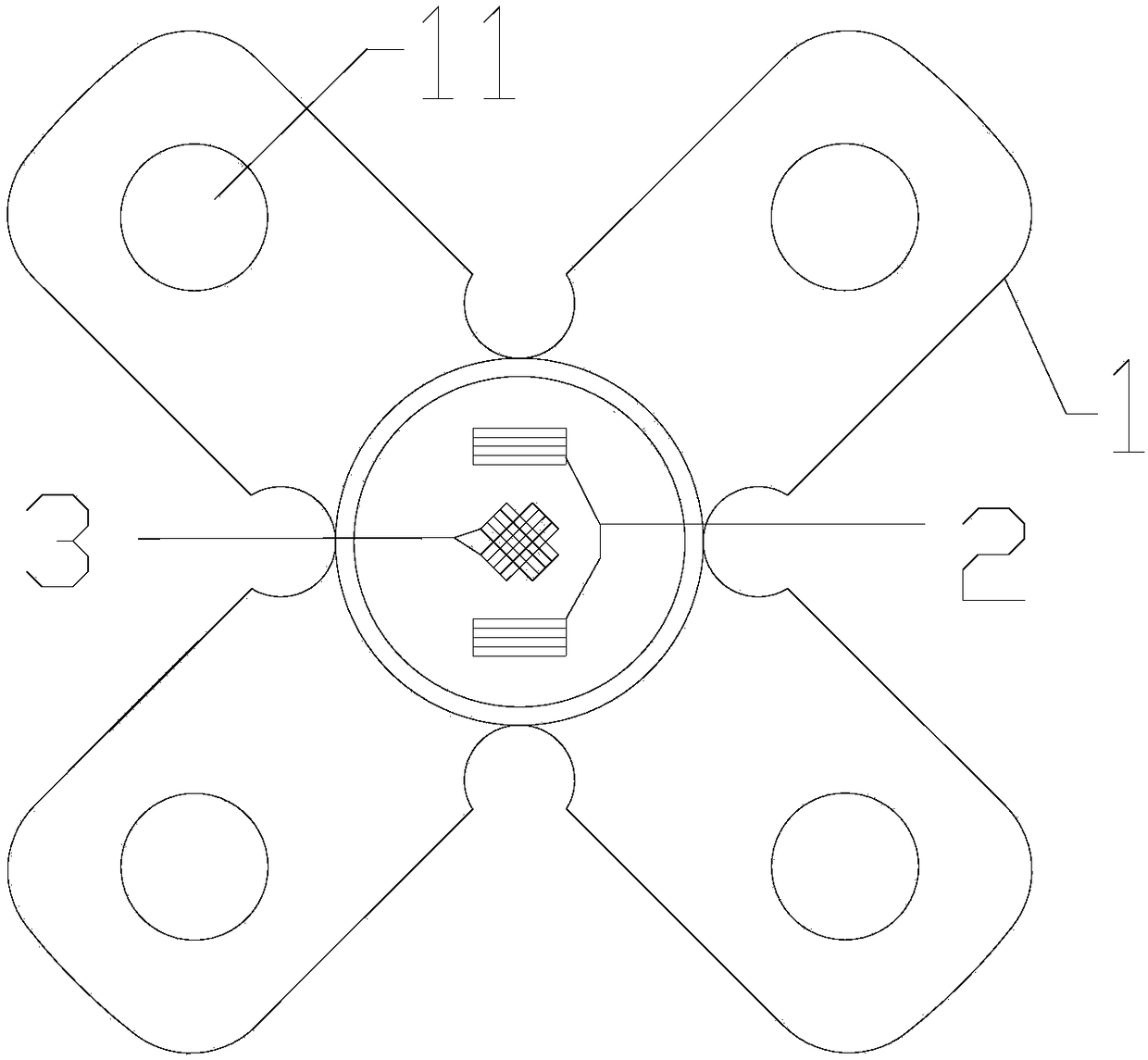

[0029] This embodiment provides a sensor, such as figure 2 As shown, it includes: two stress-sensing teeth 1 vertically connected to each other, and the overlapping parts of the two stress-sensing teeth are provided with strain gauges that elongate or contract synchronously with the stress-sensing teeth, and the strain gauges include: There are two horizontal force strain gauges 2 extending along the horizontal direction; two vertical force strain gauges 3 perpendicular to each other are arranged between the two horizontal force strain gauges.

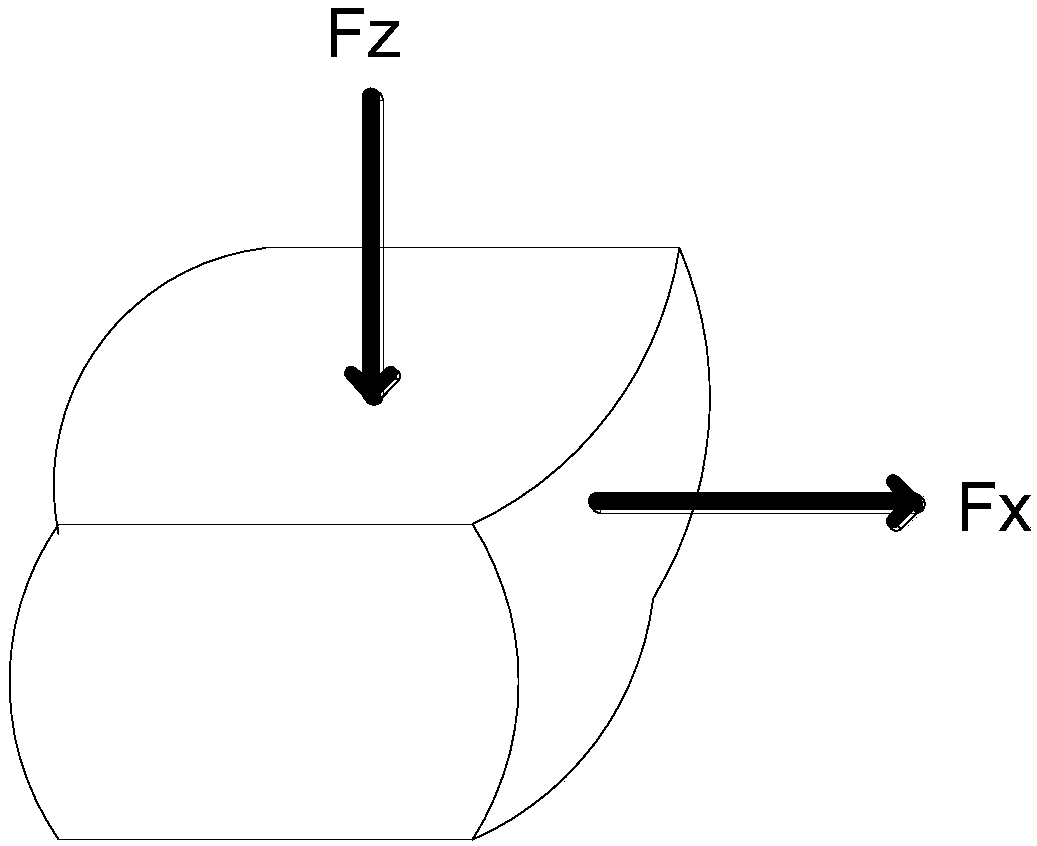

[0030] The sensor provided in this embodiment is mainly used on the horizontal force beam. The horizontal force beam is set on the ground. The vehicle's own load.

[0031] In this embodiment, the side of the stress-sensing tooth away from the strain gauge is provided with a stress-sensing slot.

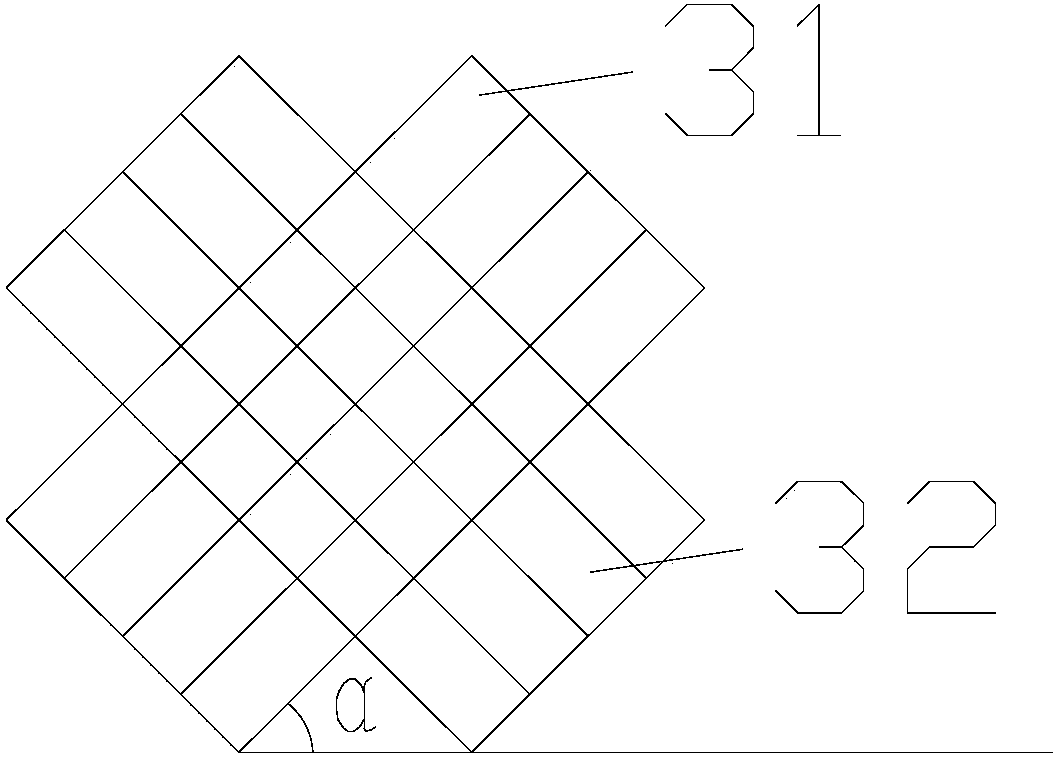

[0032] In this embodiment, the angle between any one of the two vertical force strain gauges and the horizontal line is 45° or 135°. From...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com