Combined type weighing platform paving structure

A combined and weighing platform technology, applied in the field of sensors, can solve the problem of not being able to measure the braking force and gravity of motor vehicles at the same time, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

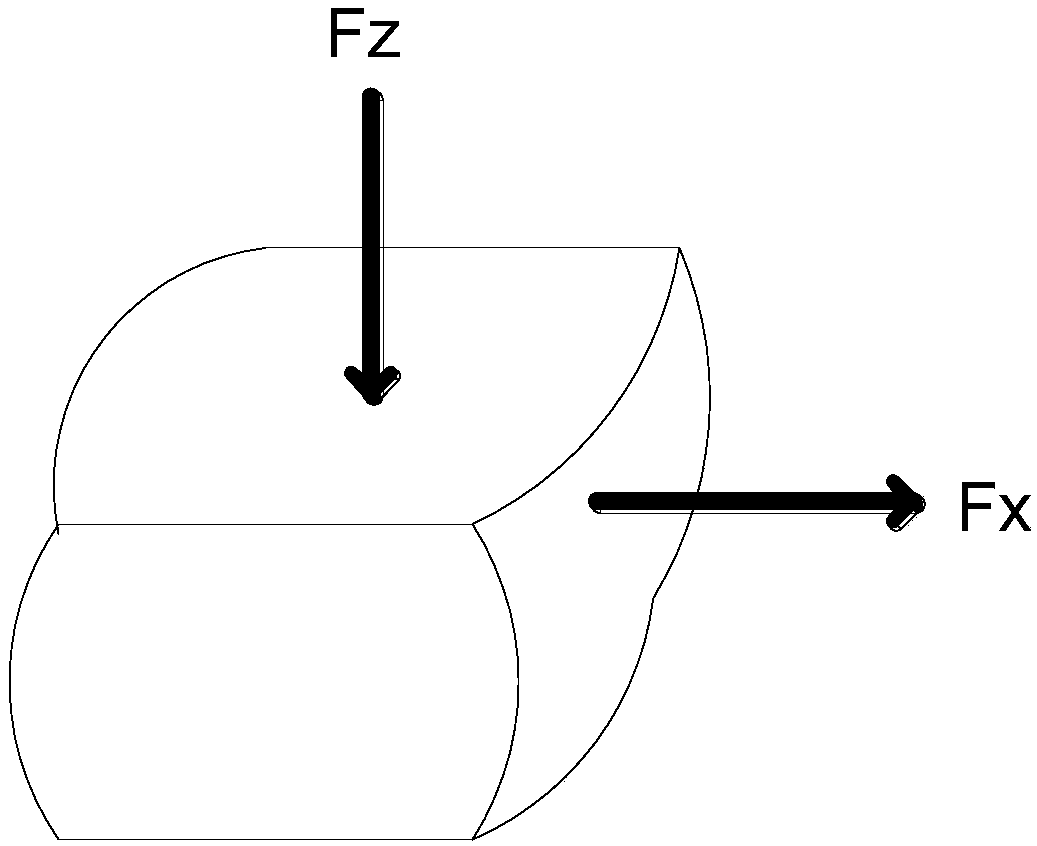

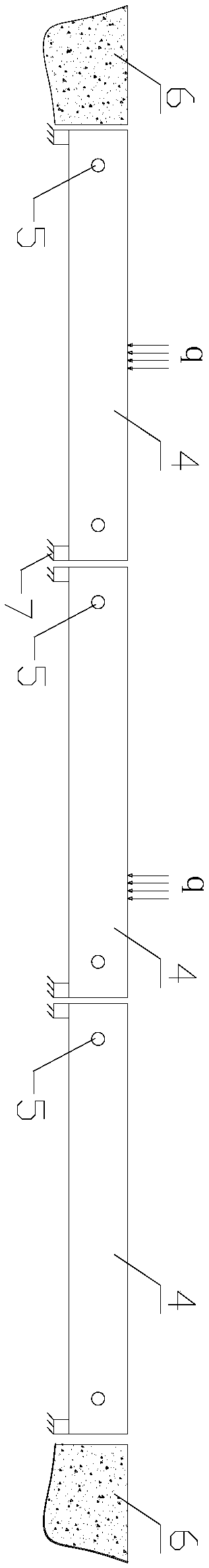

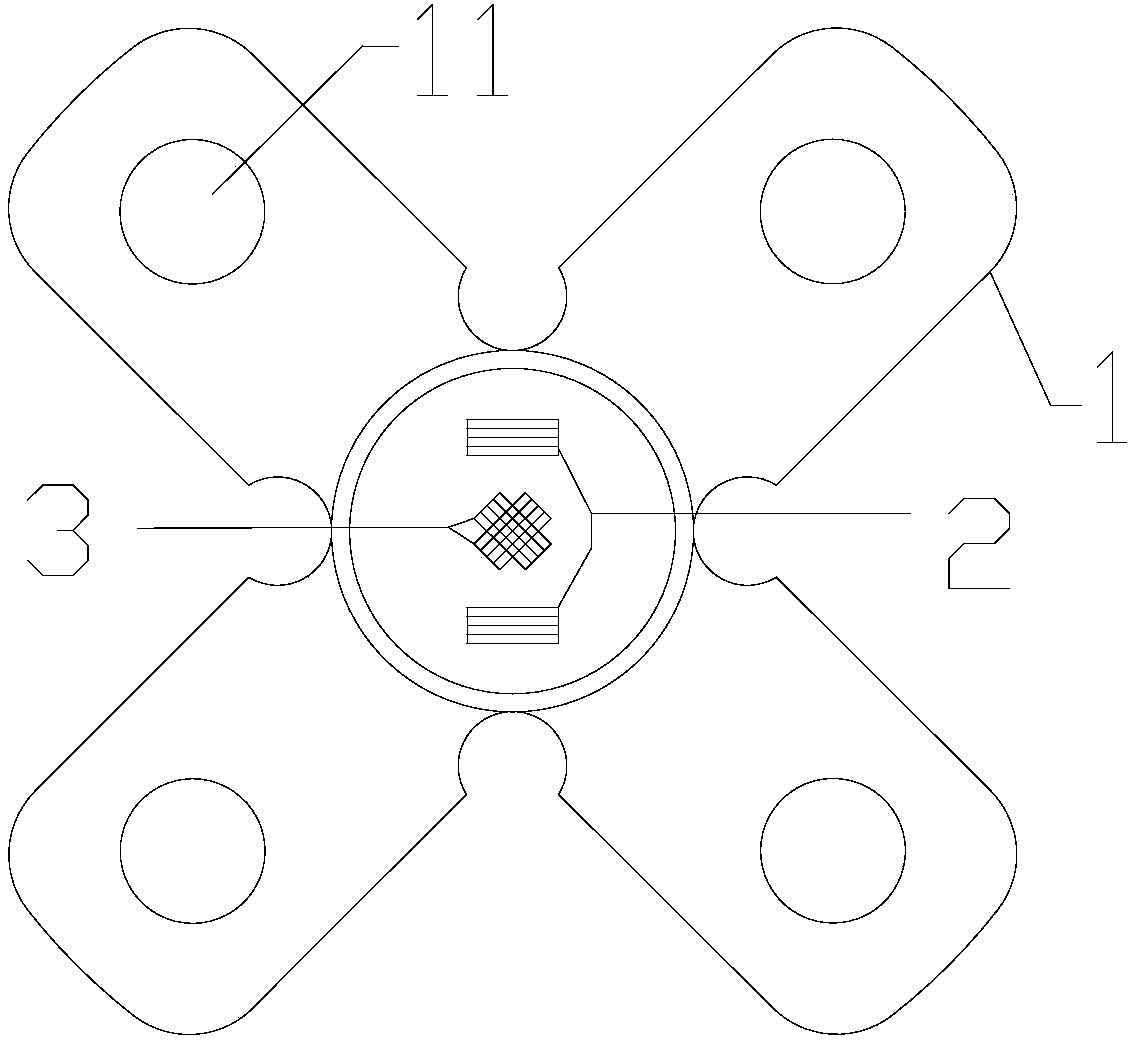

[0031] This implementation provides a combined weighing platform pavement structure, such as figure 2 As shown, it is mainly used to measure the load of the braking force on each axle group during the braking process of a multi-axle group motor vehicle. It includes: two sets of subgrades 6 arranged at both ends along the length direction of the weighing platform, and accommodating grooves are arranged between the two sets of subgrades 6; at least two stressed beams 4 arranged side by side along the length direction are arranged on the said platform Inside the accommodating groove, the stressed beam can be deformed under load; several sensors are installed on the side walls of each stressed beam 4, and when the stressed beam 4 is deformed, the The sensor deforms synchronously with the stressed beam 4, so that the sensor outputs a signal corresponding to the deformation of the stressed beam 4; the sensor includes: two stress-sensing teeth 1 connected vertically to each other, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com