Backlight module and display device

A backlight module, backlight display technology, applied in the direction of light guide, optics, optical components, etc., to achieve the effect of improving the light mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

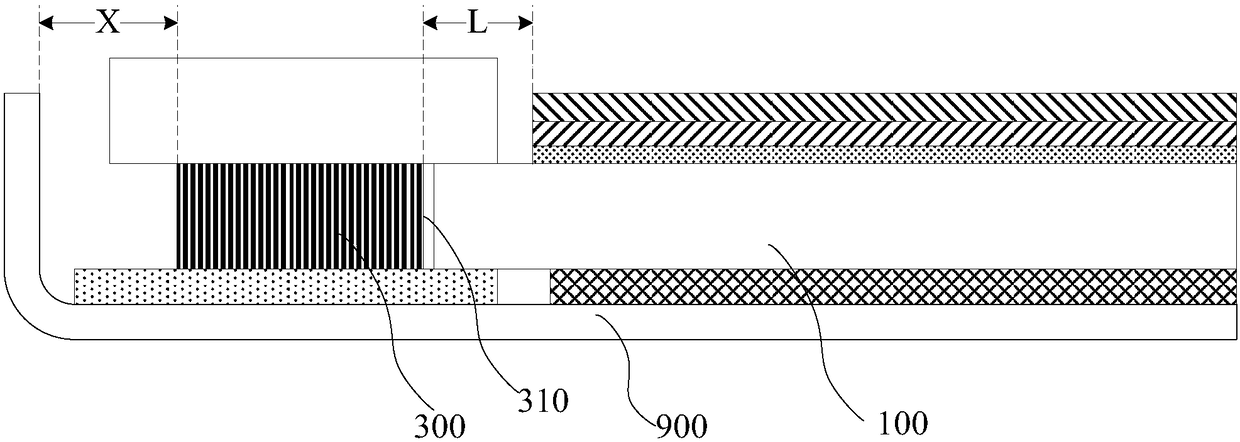

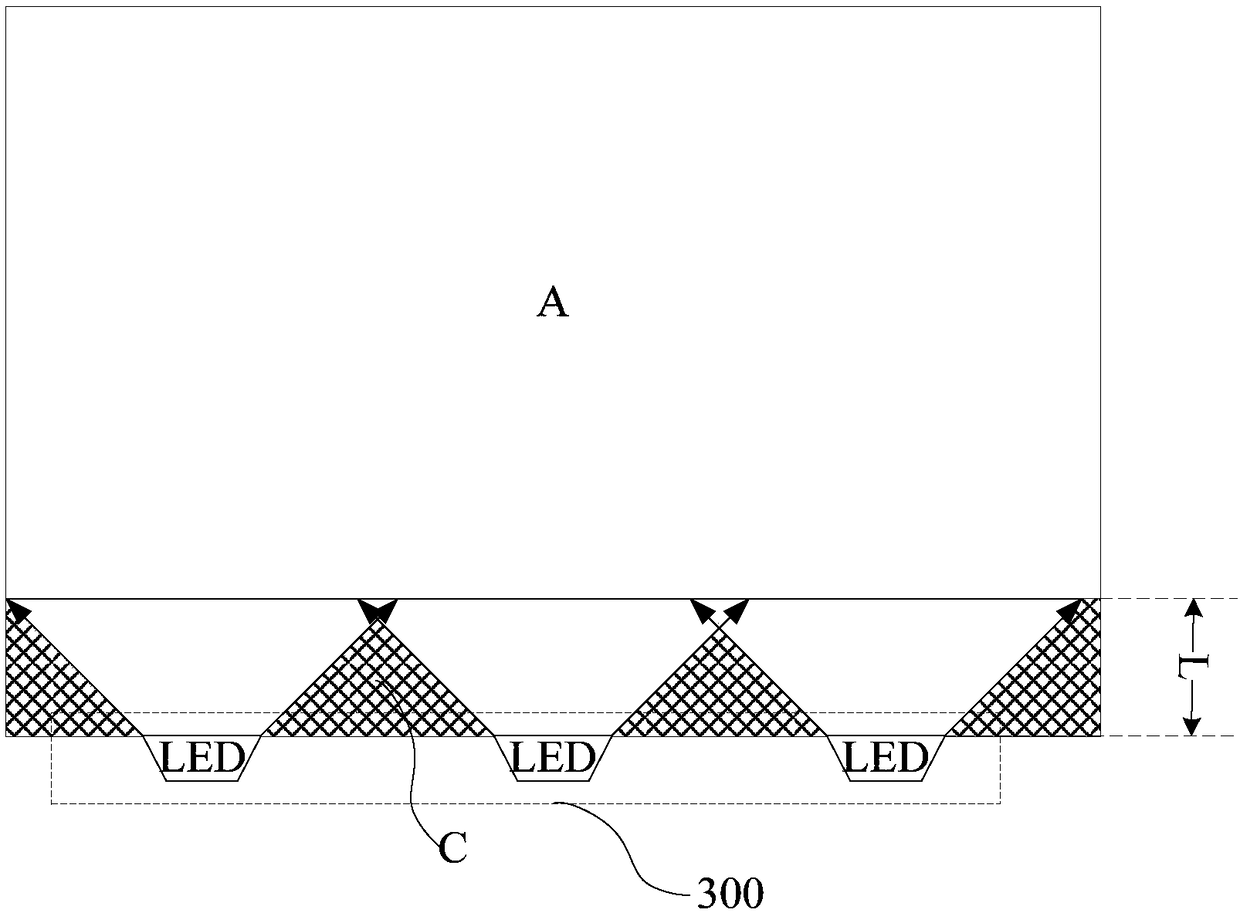

[0041] At present, in the backlight module, such as figure 1 As shown, the side-type backlight 300 is incident on the side of the light guide plate 100 , and its light emitting surface 310 faces the light guide plate 100 . Since the dimension X between the side-type backlight 300 and the outermost side of the backplane 900 involves the requirements of the FPC trace width and the reliability adhesive area, the dimension X of this part has a limit requirement and cannot be compressed. When the frame needs to be narrowed, the light mixing distance L will be compressed, that is, the distance from the light emitting surface 310 of the side-type backlight 300 to the backlight display area A of the light guide plate 100 . Such as figure 2 As shown, when the light mixing distance is small, the dark area C between the LED lights in the side-lit backlight 300 will stand out, forming a firefly effect.

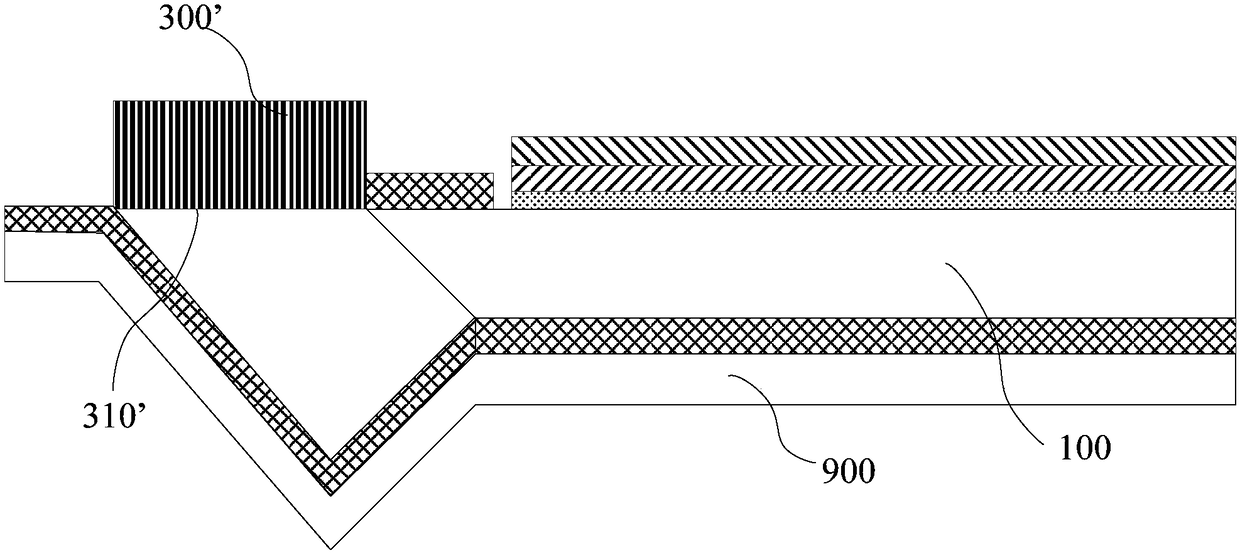

[0042] Similarly, if image 3 As shown, in the backlight module, the direct-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com