Cooling water channel structure suitable for Pin-Fin power semiconductor module

A power semiconductor, pin-fin technology, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of poor cooling effect, unbalanced heat dissipation, adverse overall life of power semiconductor modules, etc. Overall life, effect of optimized runner design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

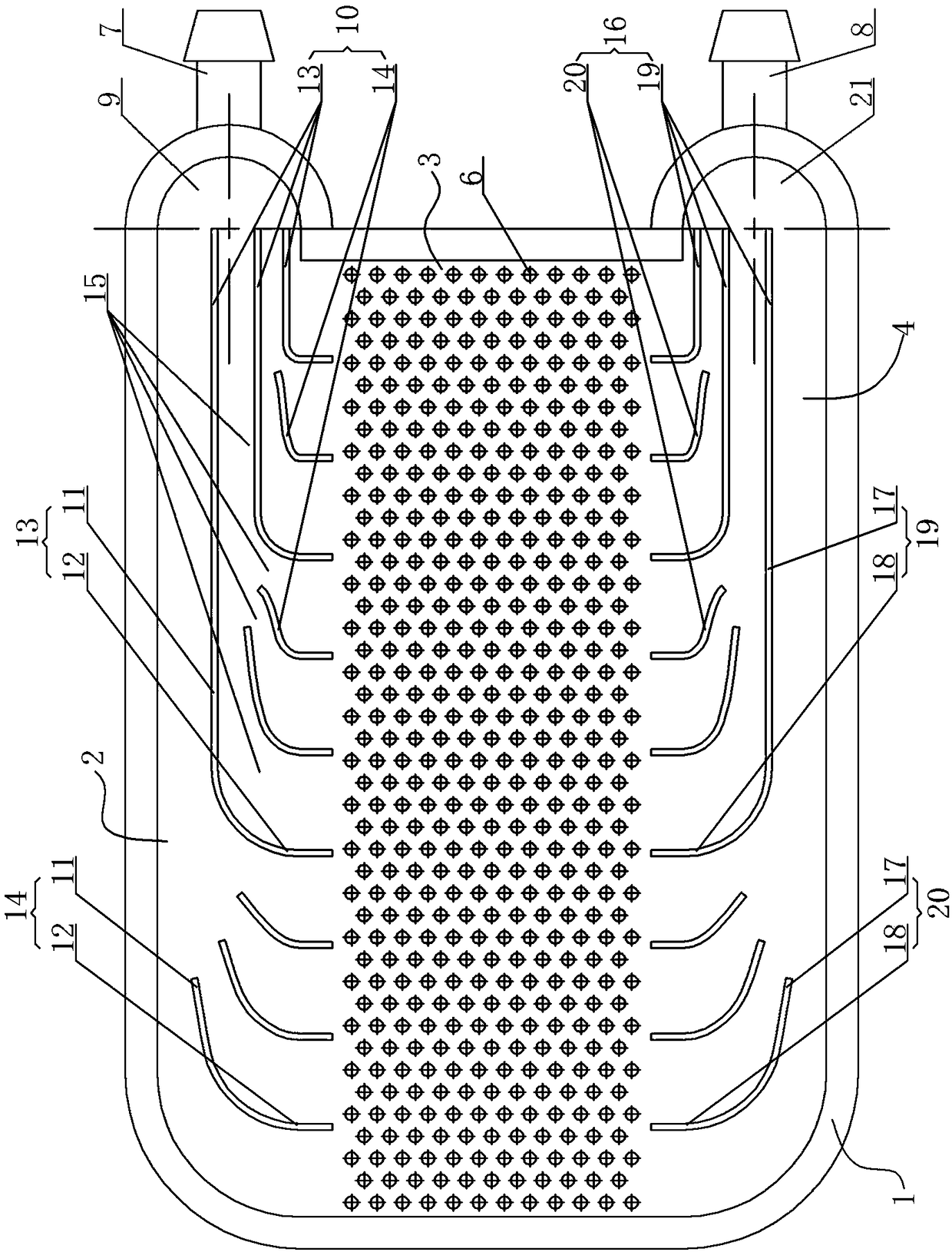

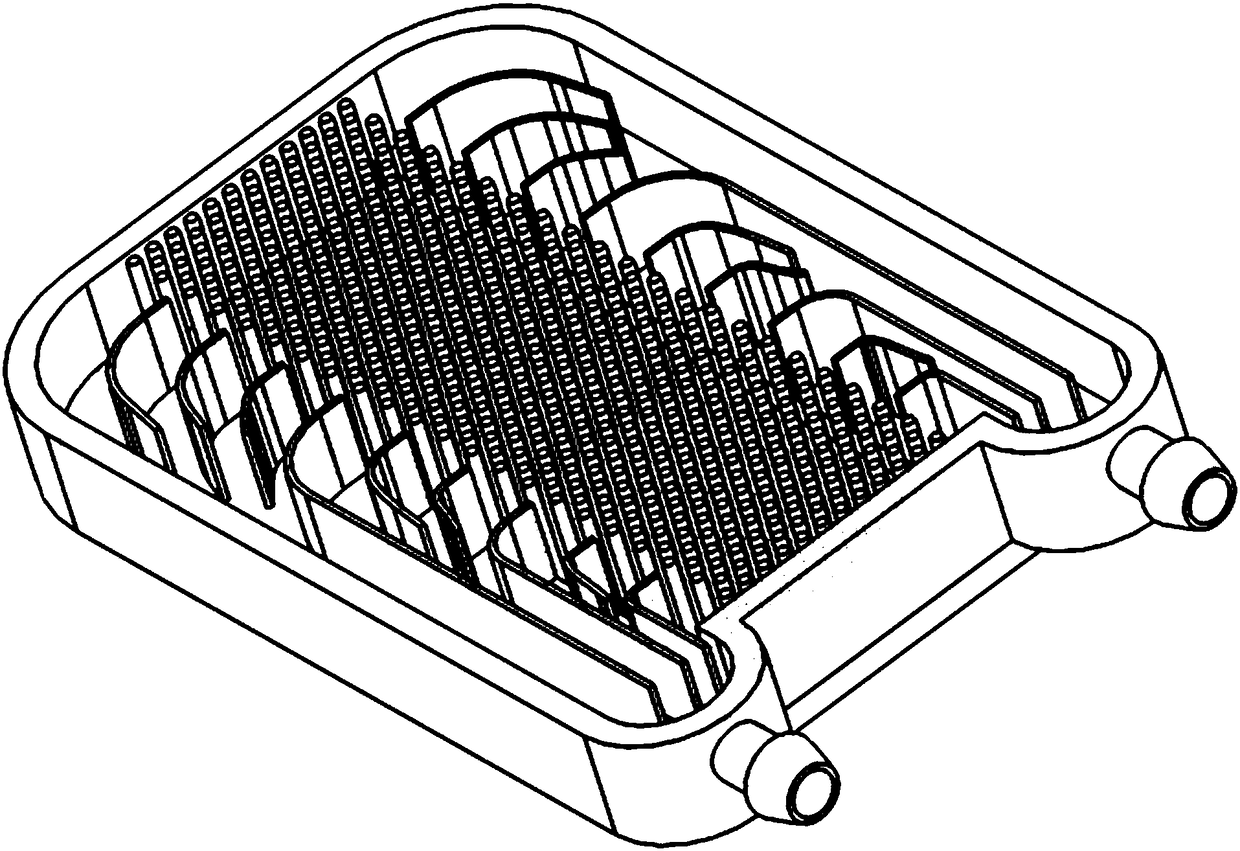

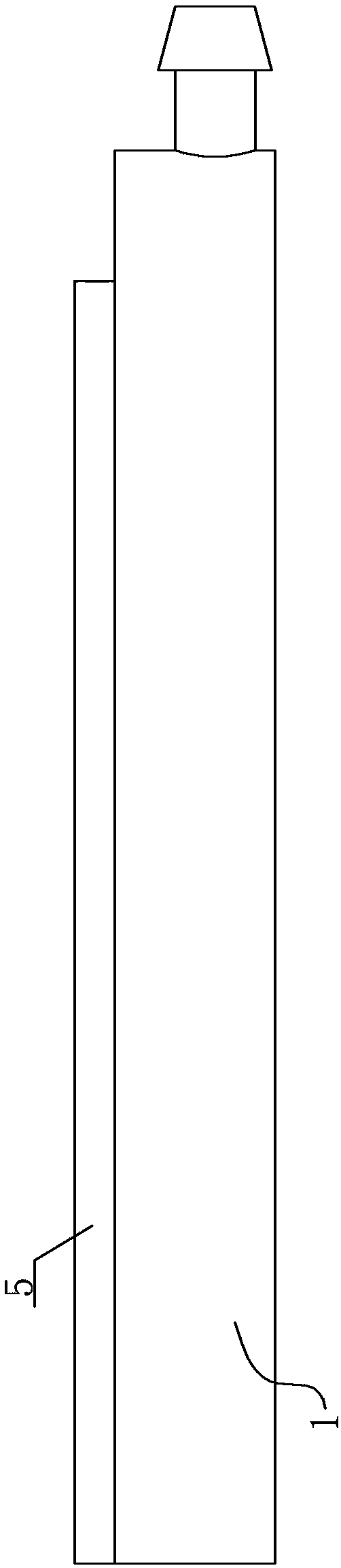

[0023] A cooling channel structure suitable for Pin-Fin power semiconductor modules, see Figure 1-Figure 3 : It includes a waterway housing 1, a liquid inlet chamber 2, a cooling chamber 3, and a liquid outlet chamber 4 are arranged in parallel in the inner cavity formed by the waterway housing 1, and liquid inlet chambers are respectively arranged on both sides of the long side of the cooling chamber 3 2. The liquid outlet chamber 4, the lower part of the Pin-Fin pin 6 at the bottom of the power semiconductor module 5 is placed in the cooling chamber 3 and evenly arranged, one end of the liquid inlet chamber 3 is provided with a liquid inlet interface 7, and the outer wall of the liquid outlet chamber 4 A liquid outlet interface 8 is provided, and a first guide area 9 is provided at the connection area between the liquid inlet interface 7 and the liquid inlet chamber 2, and N pieces of liquid inlet guide plates are arranged at the rear of the first guide area 9 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com