Welding device for large weak-rigidity thin-wall component of nuclear reactor coolant pump

A coolant pump and thin-walled component technology, which is applied to the field of large-scale weak-stiffness thin-walled component welding devices for nuclear reactor coolant pumps, can solve problems such as aggravating the welding difficulties of thin-walled components, and achieves avoiding quality problems in assembly and welding. Guaranteed effect of manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

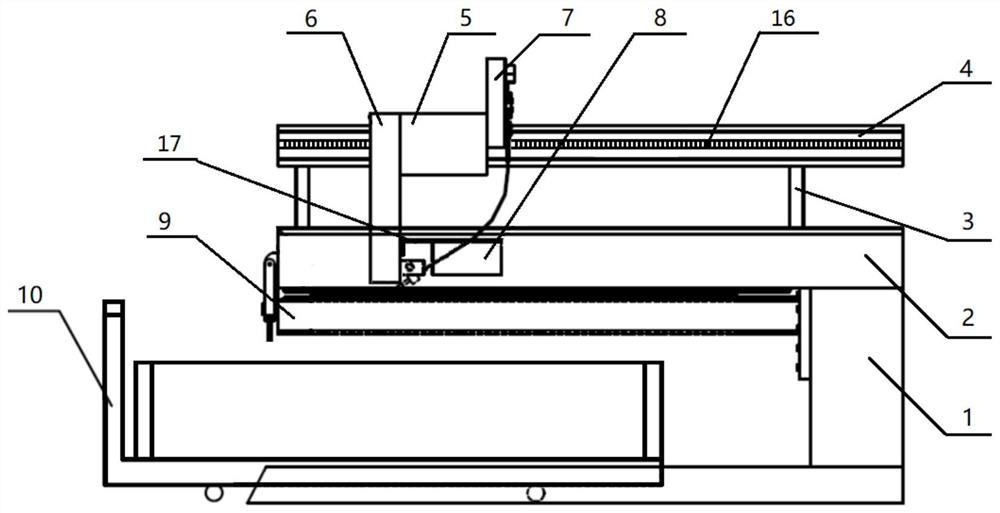

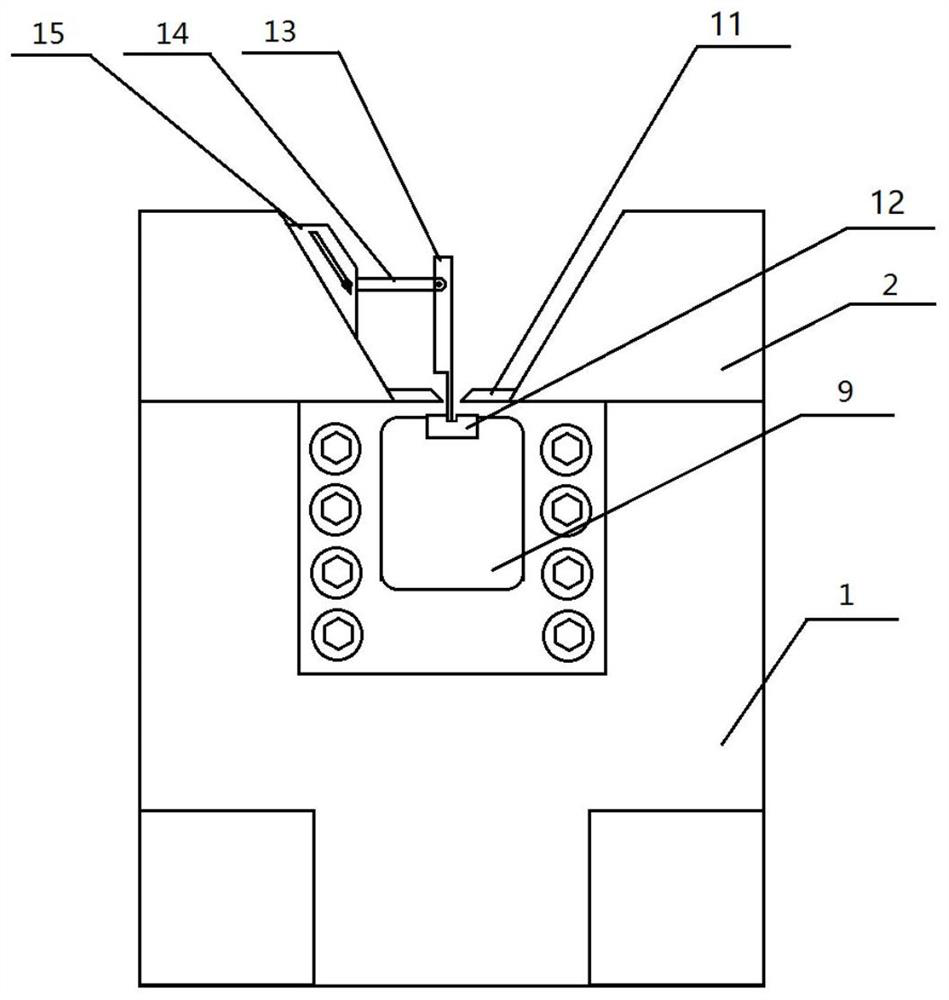

[0019] Such as figure 1 Shown is a schematic diagram of a laser welding device for a large weakly rigid thin-walled component of a nuclear reactor coolant pump. The upper part of the rigid bed 1 is the bed workbench 2. The beam 4 is fixed on the bed workbench through the column 3, and the rail is installed on the beam 4. 16. The track 16 is a rack structure, and the gear of the traveling trolley 5 meshes with the rack to realize walking on the beam 4 . The laser head 6 and the wire feeding assembly 7 are assembled on the traveling trolley 5 through bolts. The seam tracker 8 is assembled on the laser head 6 through the L-shaped bracket 17, and the seam tracker 8 is located on the front side of the laser head 6 in the welding direction, so as to realize the real-time positioning function during the welding process.

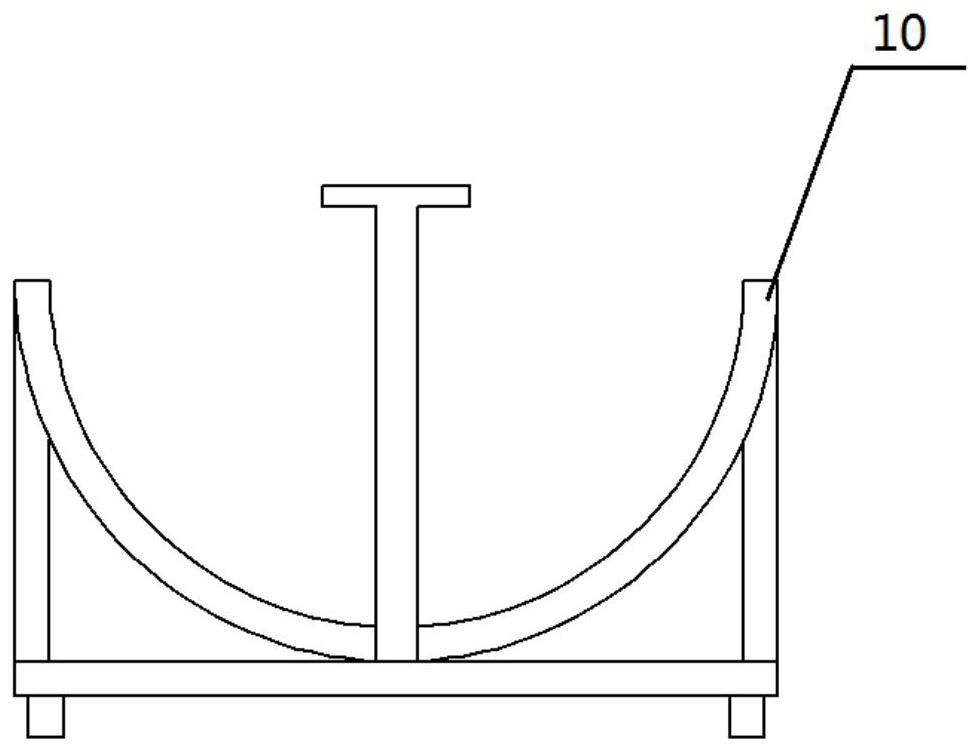

[0020] Such as image 3 As shown, the mobile trolley 10 is located below the mandrel 9, and the working surface of the mobile trolley 10 is in a semi-arc shape, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com