Aluminum alloy foil

A technology of aluminum alloy foil and aluminum alloy, applied in the field of aluminum alloy foil, can solve the problems of high cost, unreusable containers, and containers that can only be discarded, etc., and achieves the effects of sufficient deformation, prevention of container deflection, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

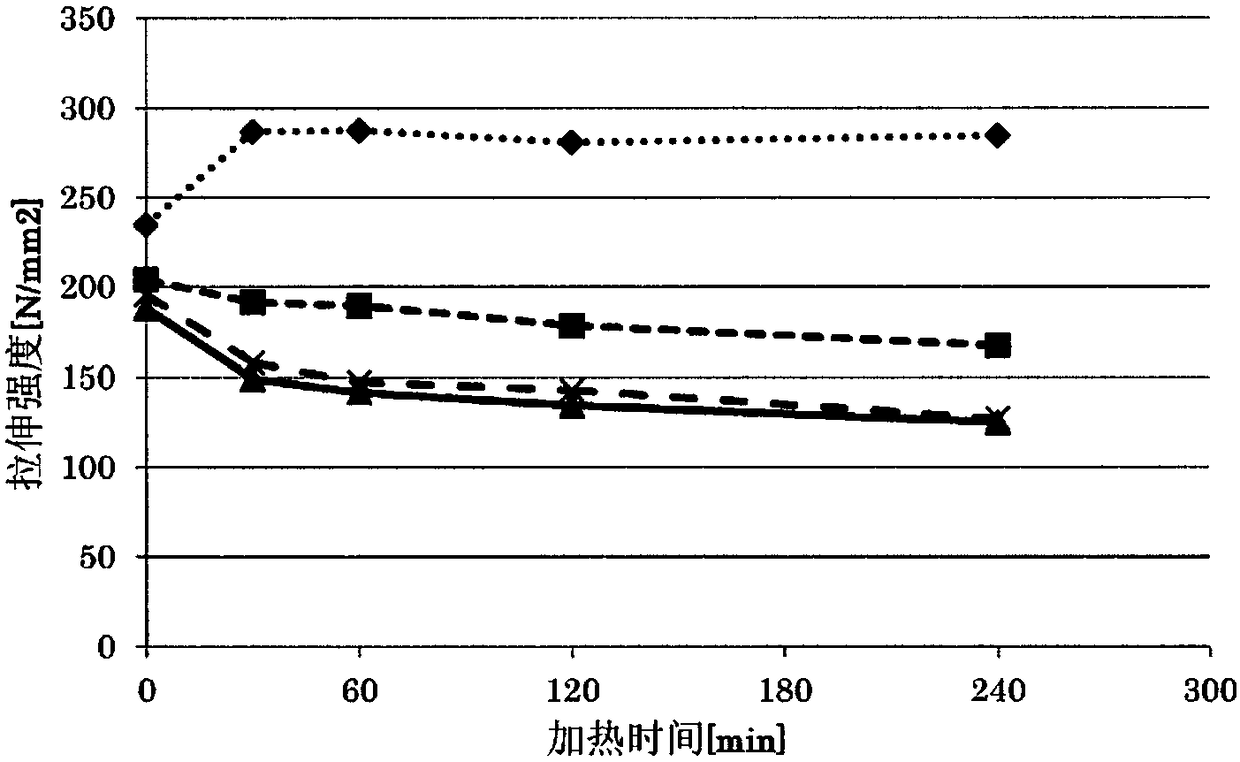

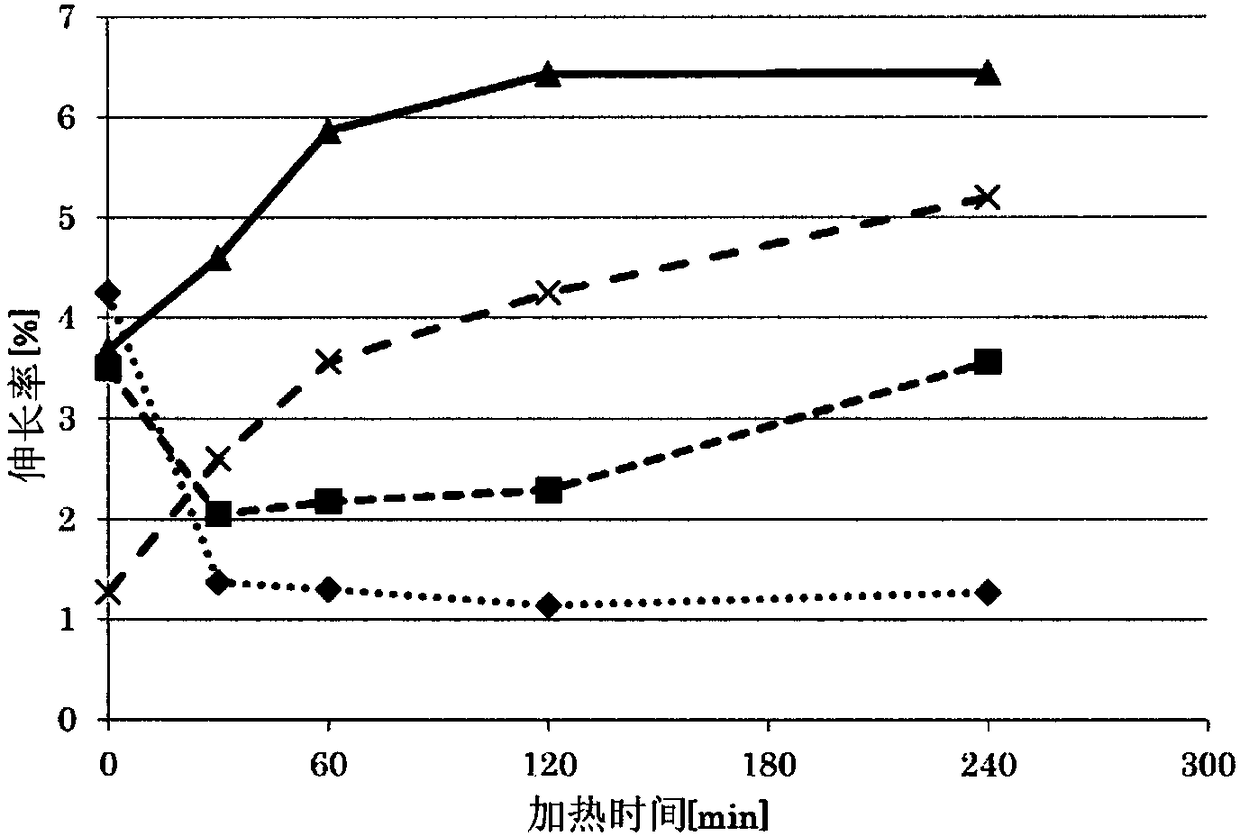

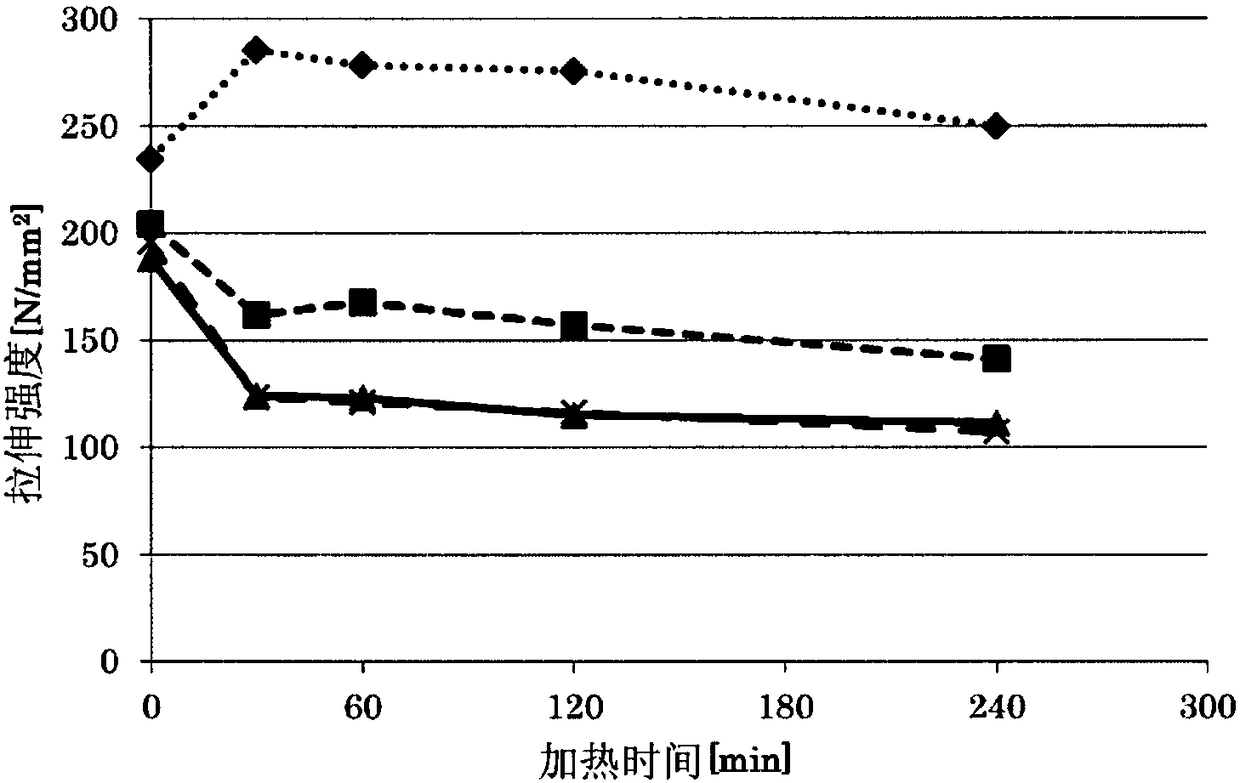

[0082] Hereinafter, examples and comparative examples are given to further clarify the present invention.

[0083] As Examples 1 to 3, the aluminum alloy sheets obtained by continuous casting according to the alloy composition in Table 1 below were subjected to intermediate annealing at a temperature of 300° C. for 5 hours at a thickness of 0.5 mm after plate rolling to obtain Aluminum alloy foil with a thickness of 75 μm.

[0084] In addition, as Examples 4 to 6, the aluminum alloy sheets obtained by continuous casting according to the alloy composition in Table 1 below were subjected to intermediate annealing at a temperature of 400° C. for 5 hours at a thickness of 1.2 mm after plate rolling. , and an aluminum alloy foil with a thickness of 75 μm was obtained.

[0085] It should be noted that, regarding the range of each element in the following Table 1, the range of the chemical composition in consideration of the process capability when the alloy is produced in a large m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com