Loop forming method and device

A loop forming device and loop forming technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problems of needle wear, needle bending, failure to teach the knitting device, etc., and achieve the effect of easy and cost-effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

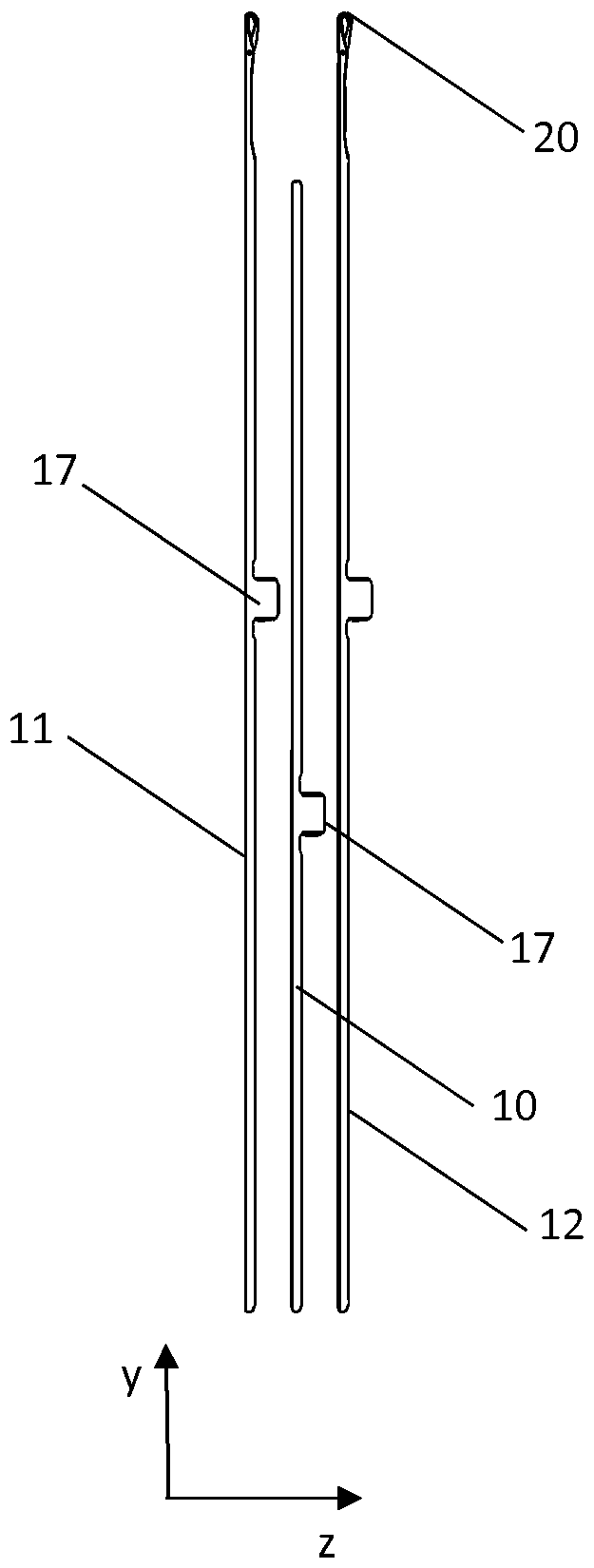

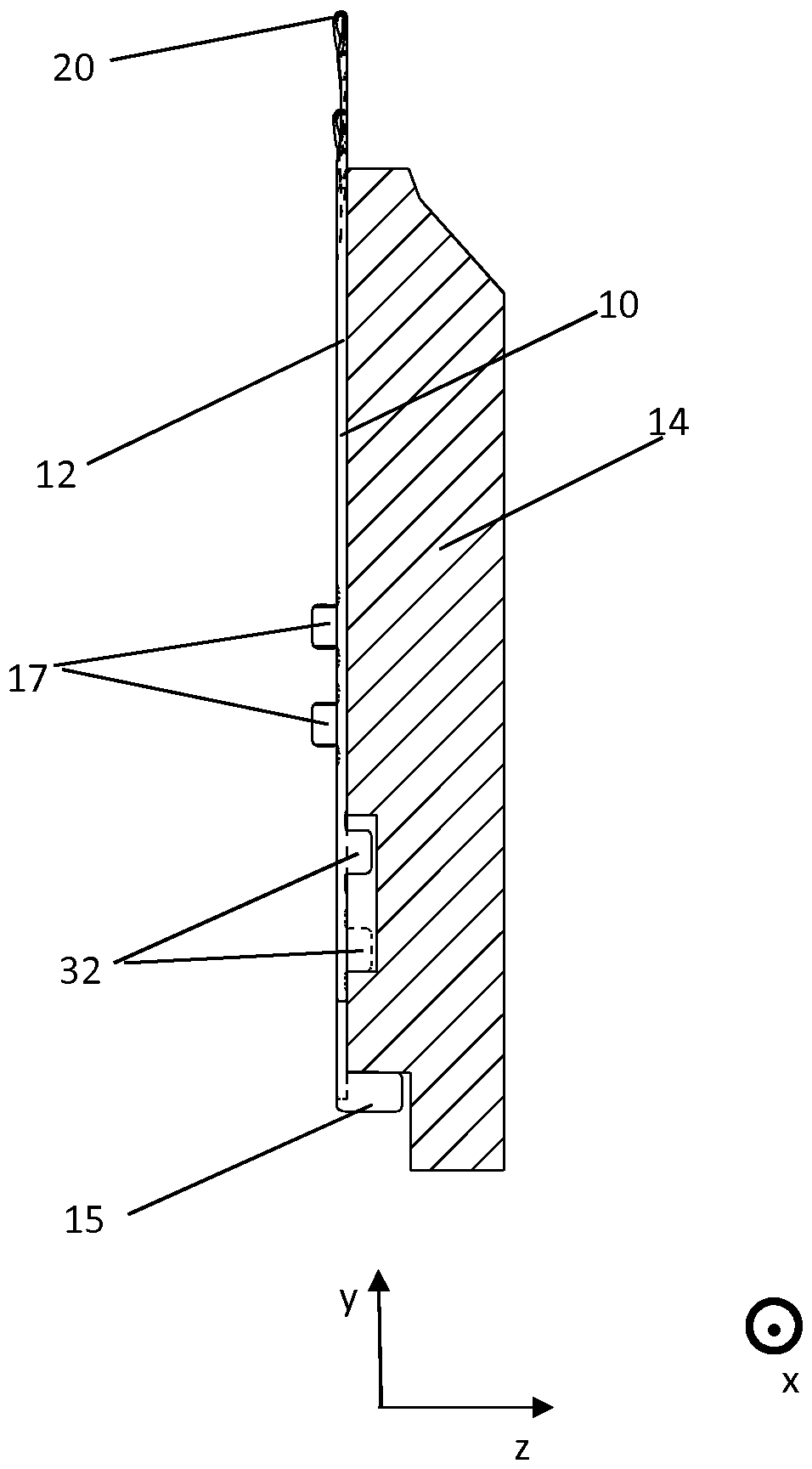

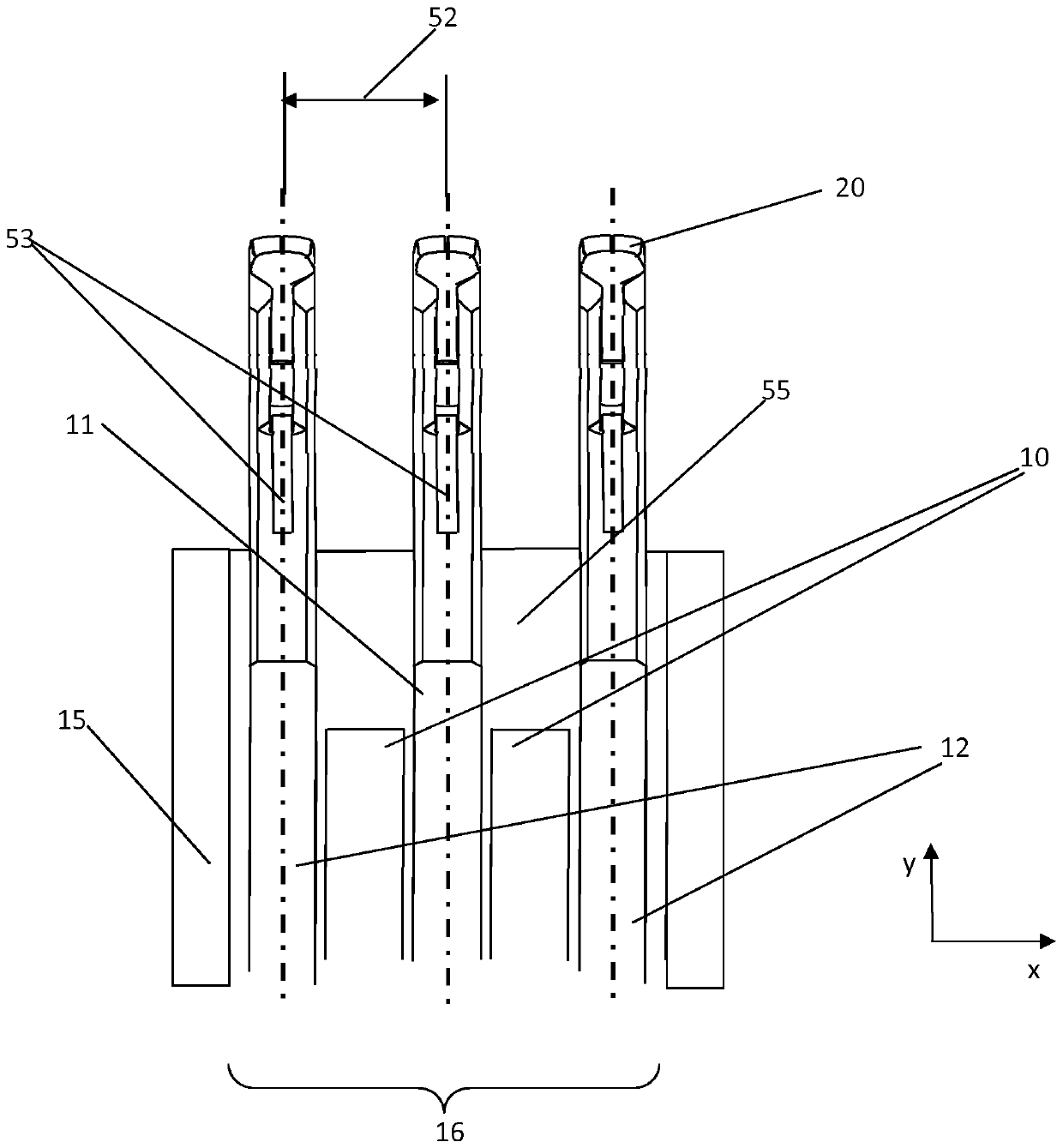

[0058] figure 1 A plan view of the first groove 16 of the needle bed 14 equipped with the system components 11, 12 is provided. Each of the system components 11 , 12 is provided with a hook 20 and a latch 24 . The hooks and latches are also collectively indicated as loop forming mechanisms 20 , 24 . A spacer 10 is present between two adjacent system components 11 , 12 . The spacer 10 has no mechanically stable connection to either of the two system components 11 , 12 .

[0059] The line 53 is a line of symmetry oriented in the longitudinal direction y parallel to the side surfaces of the handle 39 of the needle or system component 11 , 12 and passing through the center of the hook 20 of the needle. figure 1 The distance between the two lines of symmetry 53 shown in is called the pitch 52 . Since this distance representation can be made by needle bed 14 (this needle bed 14 comprises similar figure 1 This distance is well known to those skilled in the art because of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com