Cooling structure for water-cooled engine

A water-cooled engine and structure technology, which is applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems of unable to cool the exhaust side, unable to eliminate the retention of cooling water in the water jacket on the side of the cylinder block, etc., to improve the cooling effect , to prevent the effect of stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

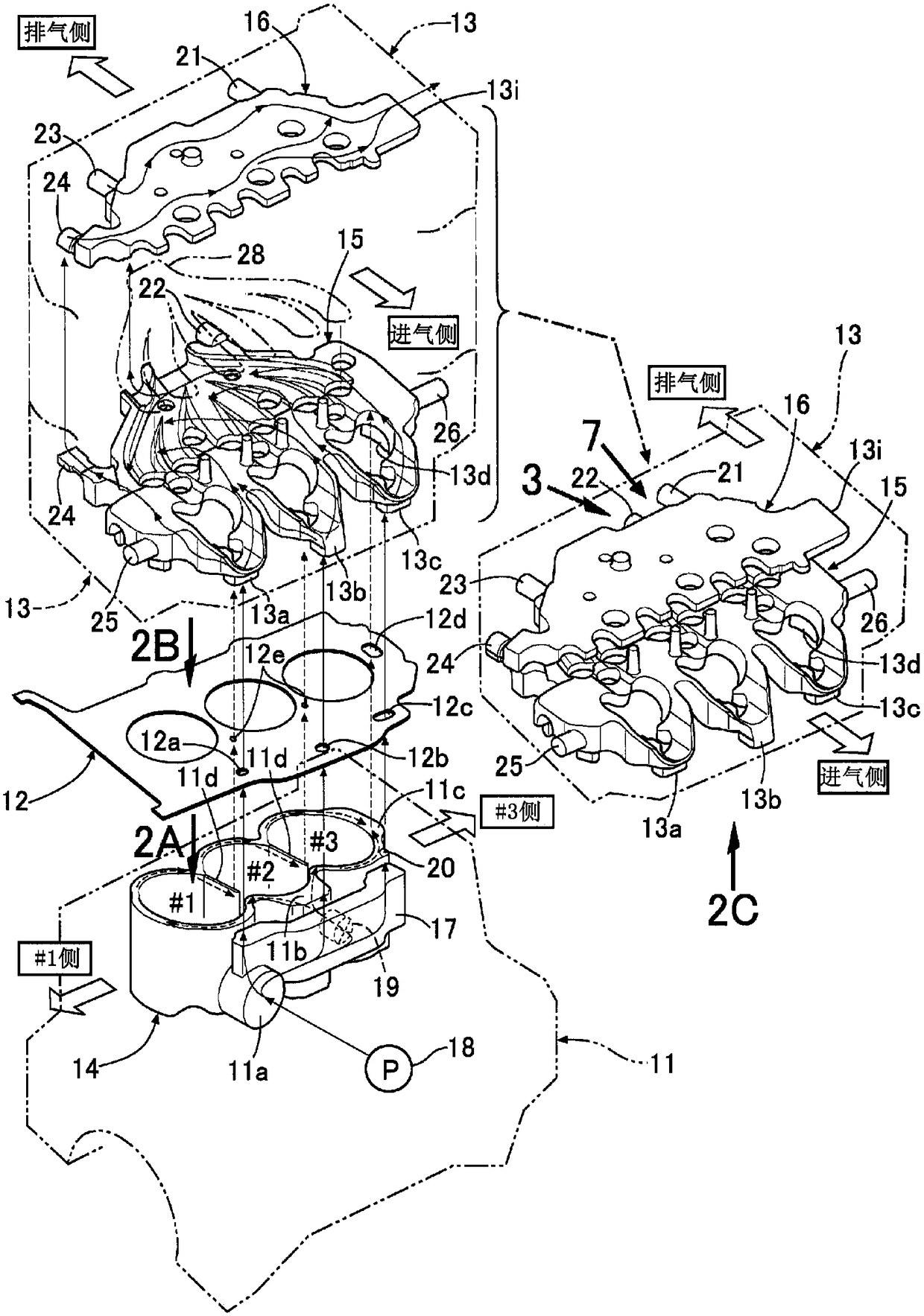

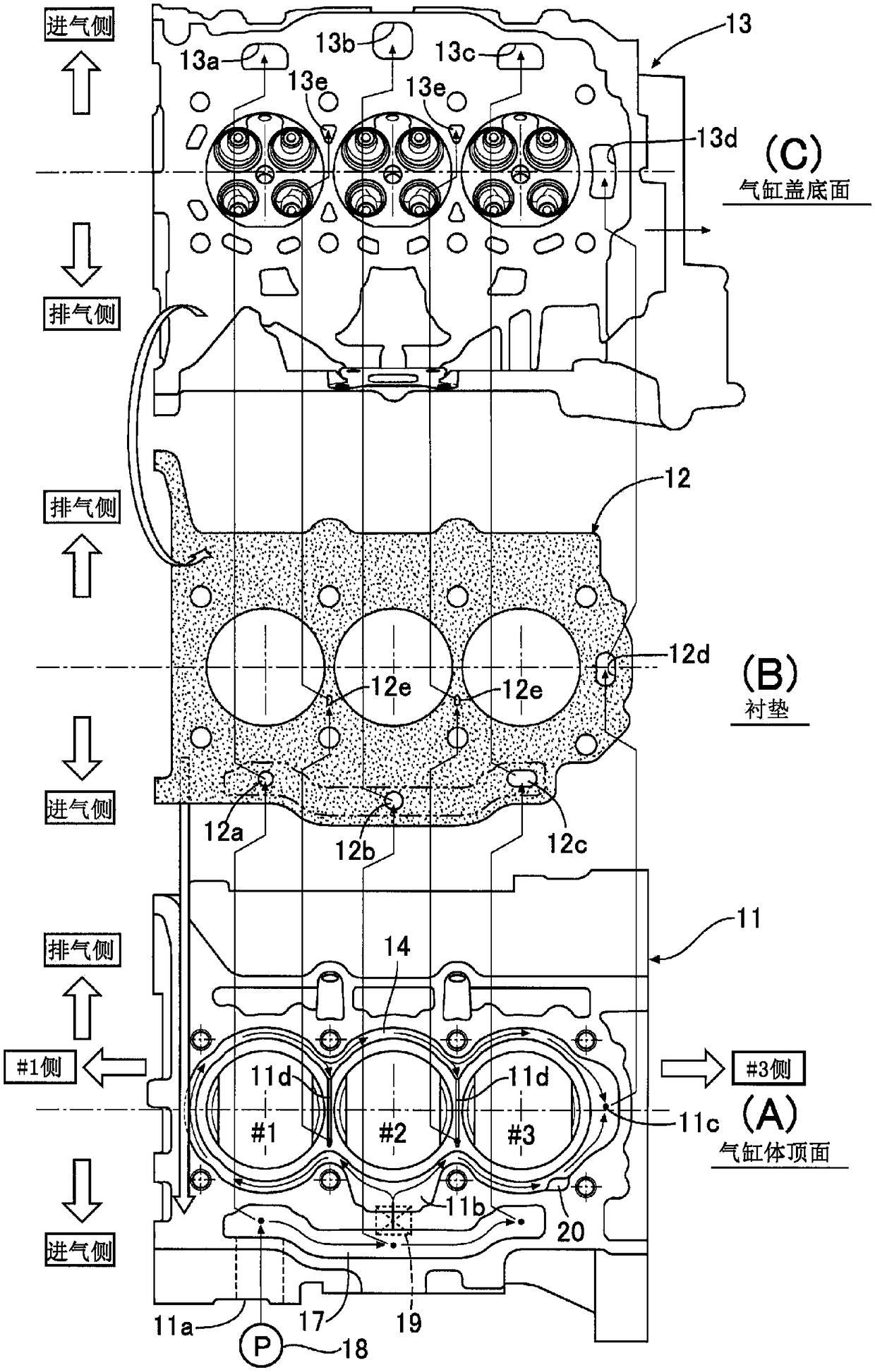

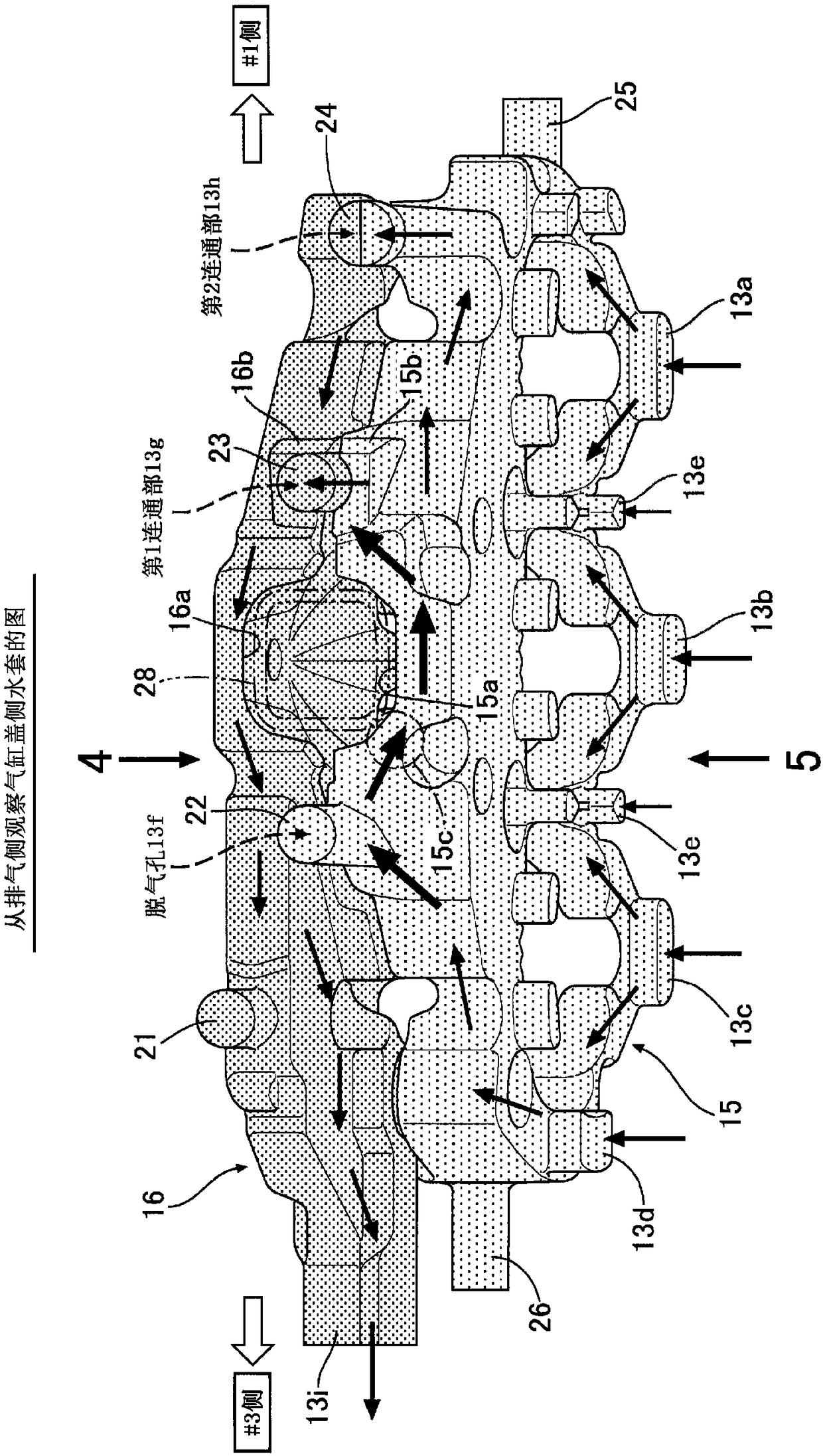

[0064] Such as figure 1 with figure 2 As shown, a water-cooled inline 3-cylinder engine has a cylinder block 11 and a cylinder head 13 whose bottom surface is coupled to the top surface of the cylinder block 11 via a gasket 12. The cylinder block 11 has a cylinder block side water jacket 14 that surrounds the three cylinder bores arranged in line along the cylinder arrangement line. In addition, the cylinder head 13 has a cylinder head that overlaps the exhaust manifold (not shown). Side lower water jacket 15 and cylinder head side upper water jacket 16. in figure 1 The upper left part of the cylinder head 13 shows only the cylinder head side lower water jacket 15 and the cylinder head 13 only shows the cylinder head side upper water jacket 16 respectively. In addition, the shape of the water jacket in each drawing is also the shape of the core of the water jacket formed by casting.

[0065] On the intake side of the cylinder block 11, an auxiliary water jacket 17 extending in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com