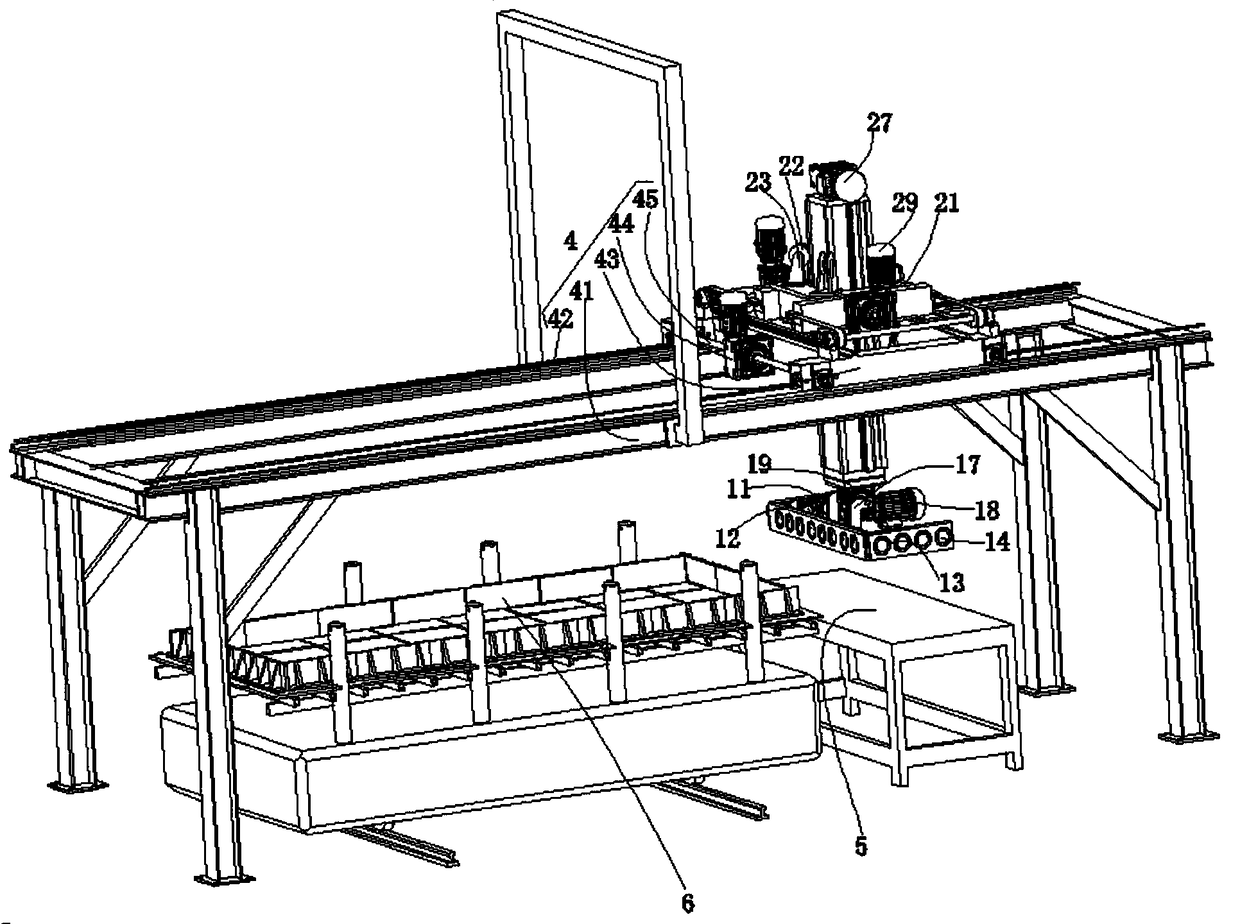

Surrounding edge paper paving machine

A technology of laying paper and surrounding edges, applied in ceramic forming machines, auxiliary forming equipment, manufacturing tools, etc., can solve the problems of high labor cost, high labor intensity, low efficiency, etc., and achieve stable and automated paper laying quality. The effect of high degree and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

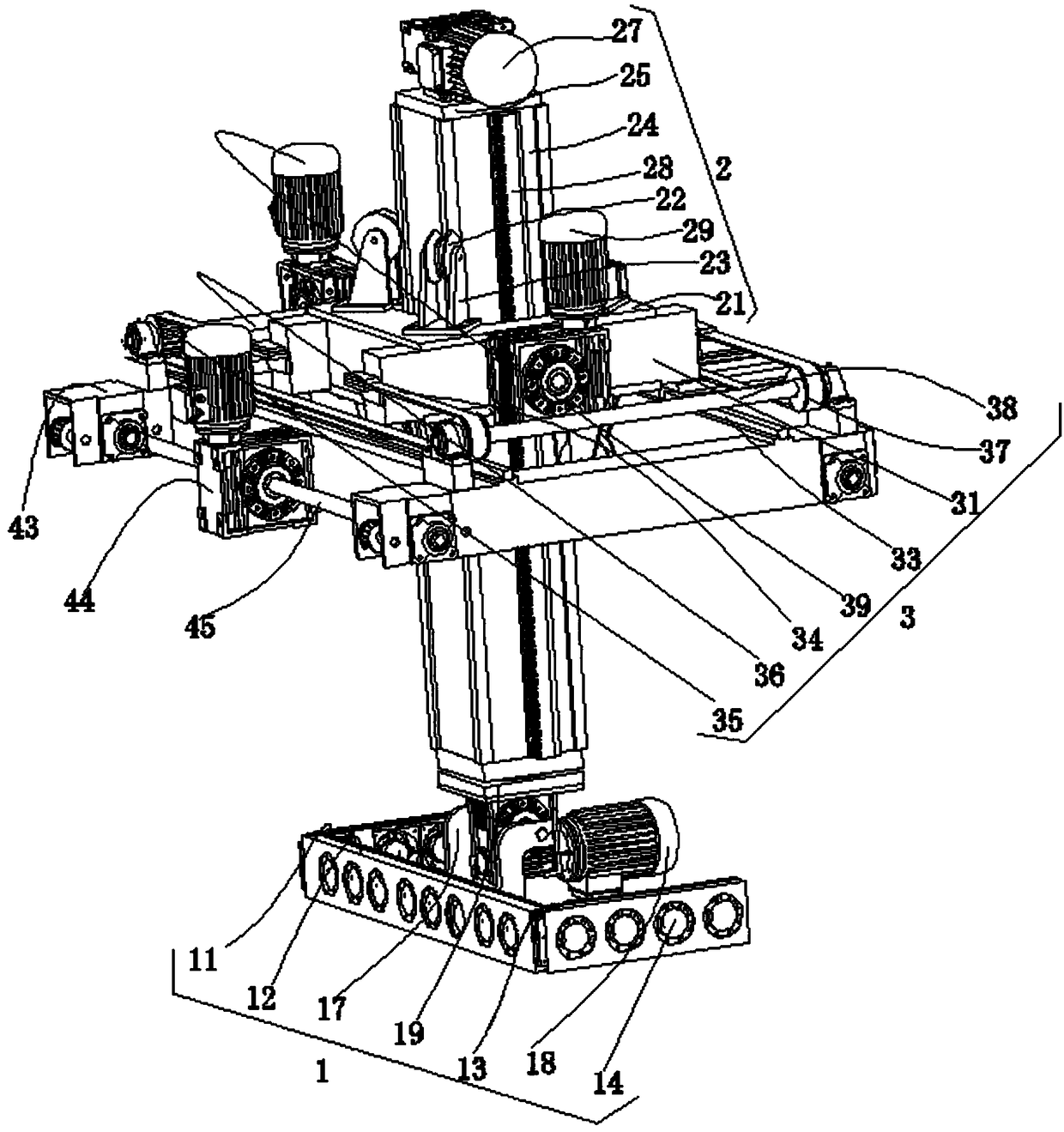

[0014] Please refer to the accompanying drawings, the present invention provides a technical solution: a wrapping paper machine, including a moving device and a paper taking mechanism 1, the moving mechanism 1 includes a left and right movement mechanism 4, a front and rear movement mechanism 3, and an up and down movement mechanism 2, front and rear The moving mechanism 3 is located above the left and right moving mechanism 4, the up and down moving mechanism 2 is movably sleeved on the front and rear moving mechanism 3, and the bottom of the up and down moving mechanism 2 is fixedly connected with the paper fetching mechanism 1; the paper fetching mechanism 1 includes the first One cardboard 11, the second cardboard 12, the third cardboard 13, fan 14, the first cylinder 15, the second cylinder 16, the swing rod 17, the first motor 18, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com