Spline claw and chaining claw diversion assembly inside valve body

A flower claw and valve body technology, applied in the direction of fluid flow, valve energy absorption device, valve details, etc., can solve the problems that the water flow cannot be separated and the diversion effect is not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

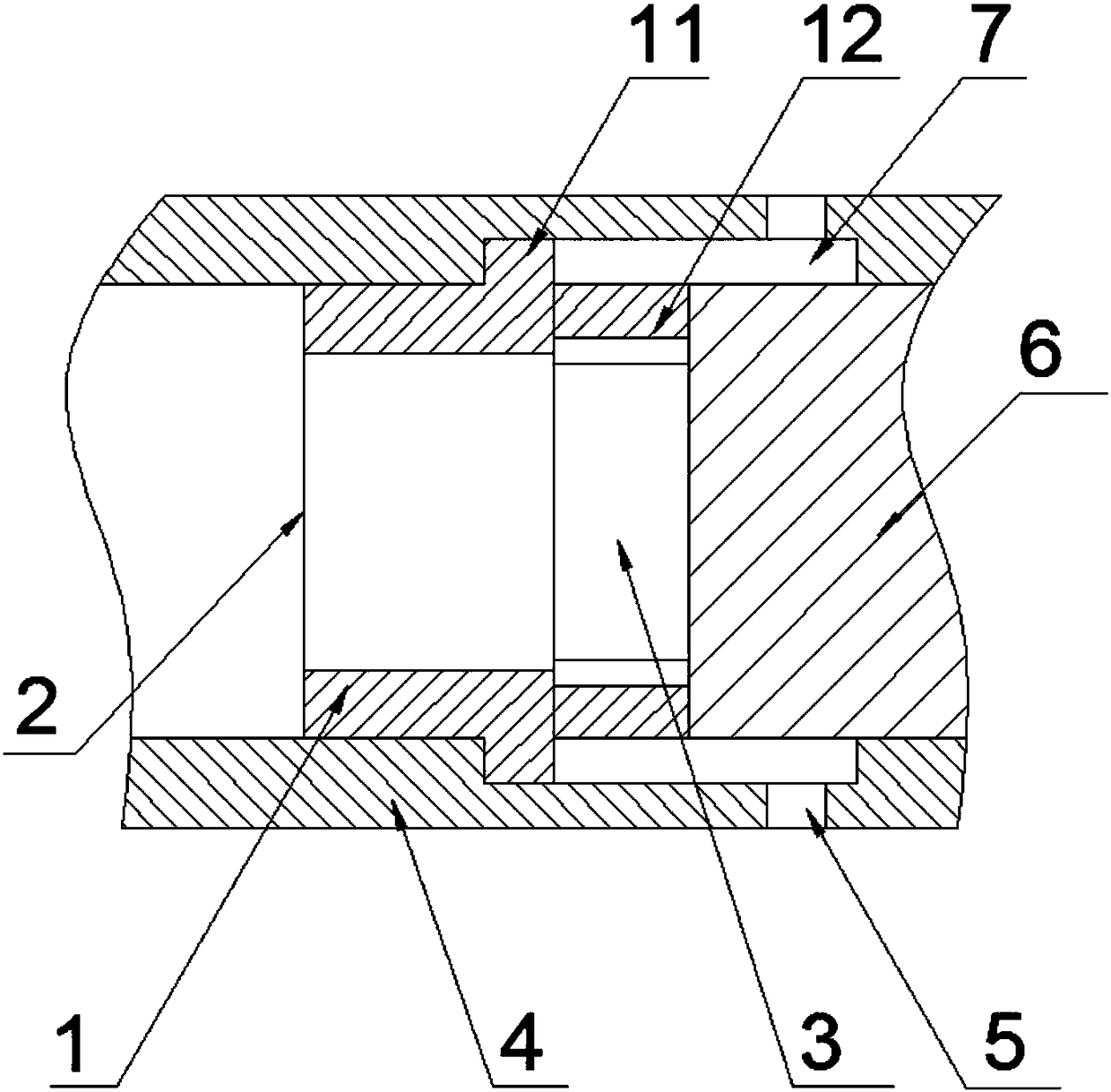

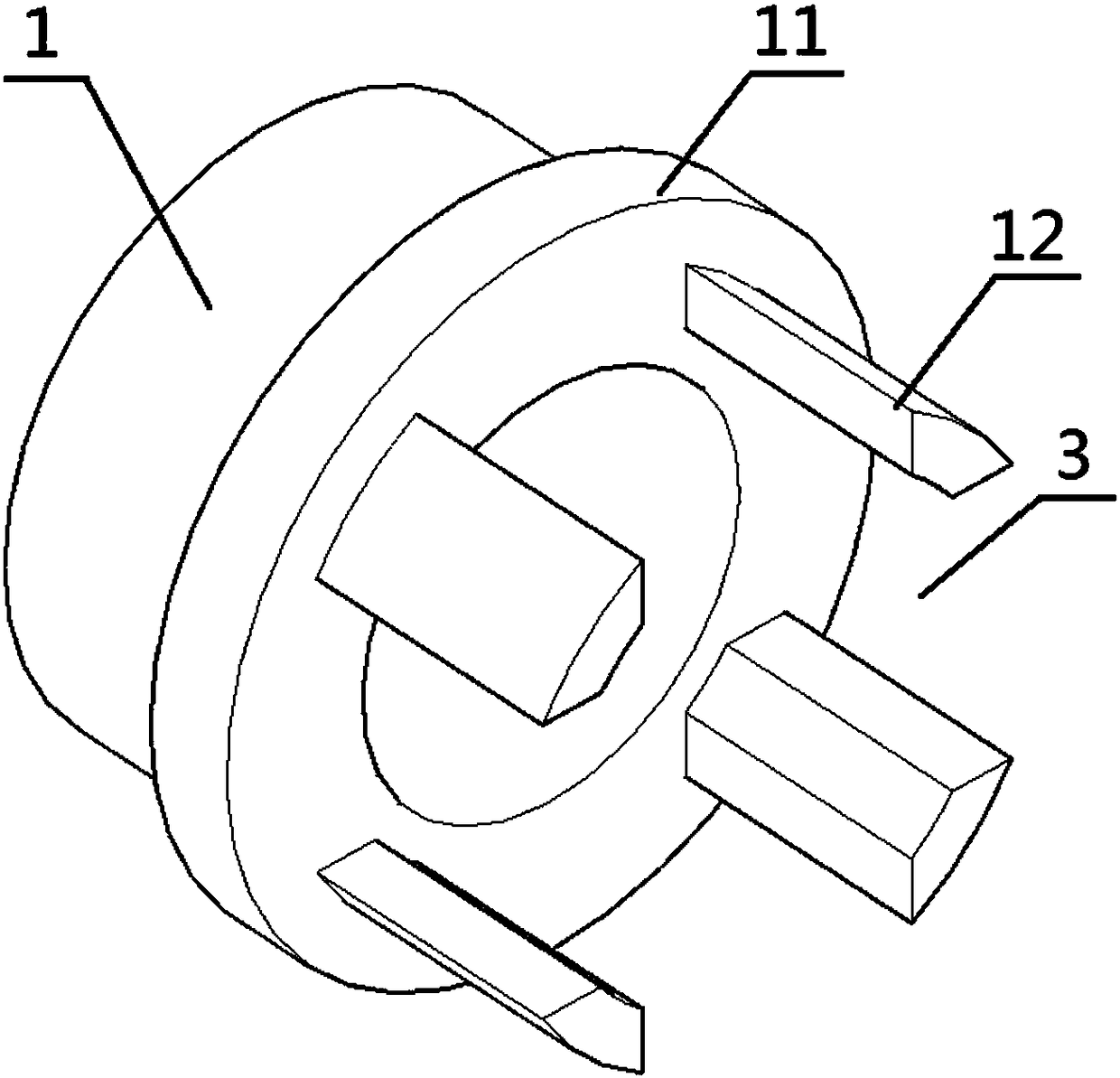

[0012] Such as Figure 1-2 as shown, figure 1 It is a schematic diagram of the overall connection of the flower claw inside the valve body and the link claw shunt assembly proposed by the present invention, figure 2 It is a schematic diagram of the structure of the connecting claw in the spline claw and the connecting claw inside the valve body proposed by the present invention.

[0013] refer to Figure 1-2 , a shunt assembly between the flower claw and the link claw inside the valve body proposed by the present invention, including the link claw 1, the flower claw 4 and the connecting part 6; , the bump 11 and the flower claw 4 are fixed at the limit; the center of the link claw 1 is provided with a through hole in the axial direction, one end of the link claw 1 is the water inlet 2, and the other end of the link claw 1 is symmetrically provided with four shunt claws 12, between the shunt claws 12 A water outlet 3 is formed, and a connecting part 6 is arranged close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com