Rail resonant grounding device

A resonant grounding and steel rail technology, which is applied in the direction of track installation, transportation and packaging, and power oscillators, etc., can solve the problems of heavy switching workload, error-prone, high traffic density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

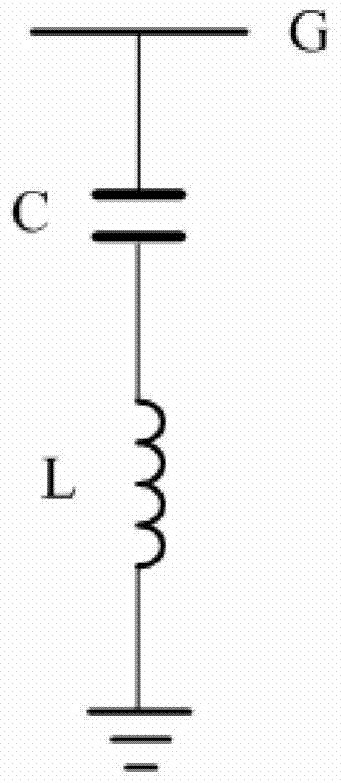

[0010] The invention is a rail resonant grounding device, which is used in the occasion of shared rails of AC and DC electrified railways. working frequency. How it works see figure 1 For specific instructions. exist figure 1 Among them, G is the rail, capacitor C and inductor L form a series resonant branch, and the resonant frequency is the operating frequency of the AC electrified railway, generally 50Hz or 60Hz. The traction current of the series resonant branch to the AC train is equivalent to a short circuit, which is automatically realized The grounding of the rail, the traction current of the DC train, due to the direct blocking effect of the capacitor, the DC traction current cannot pass through the branch to the ground, so that no stray current will be generated.

[0011] The present invention will be further described below in combination with specific embodiments.

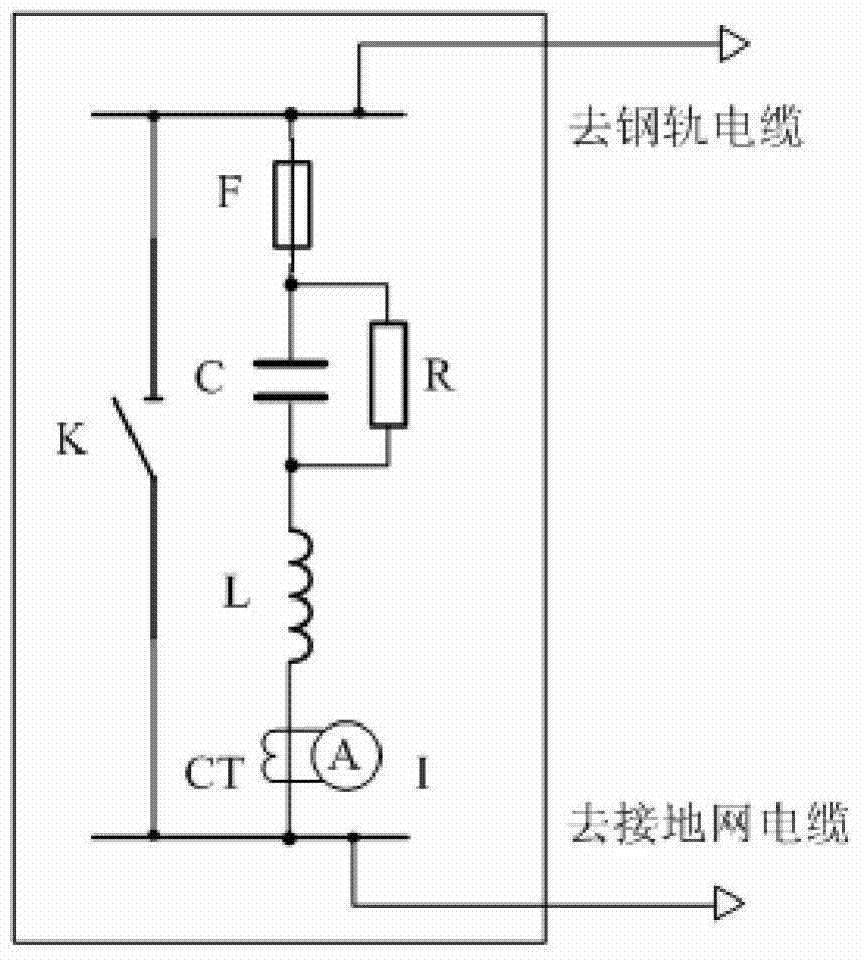

[0012] figure 2 , the capacitor C and the inductor L form an LC series resonance branch with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com