A method of calibrating heat flow meter method thermal conductivity meter based on guarded hot plate method

A technology of protective hot plate method and thermal conductivity meter, which is applied in the direction of material thermal development, etc., can solve the problems of inability to accurately calibrate the thermal conductivity meter of the heat flow meter method, and achieve the effect of avoiding inaccurate instrument measurement, avoiding repeated purchases, and achieving accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various embodiments in the present invention can be combined accordingly on the premise that there is no conflict with each other.

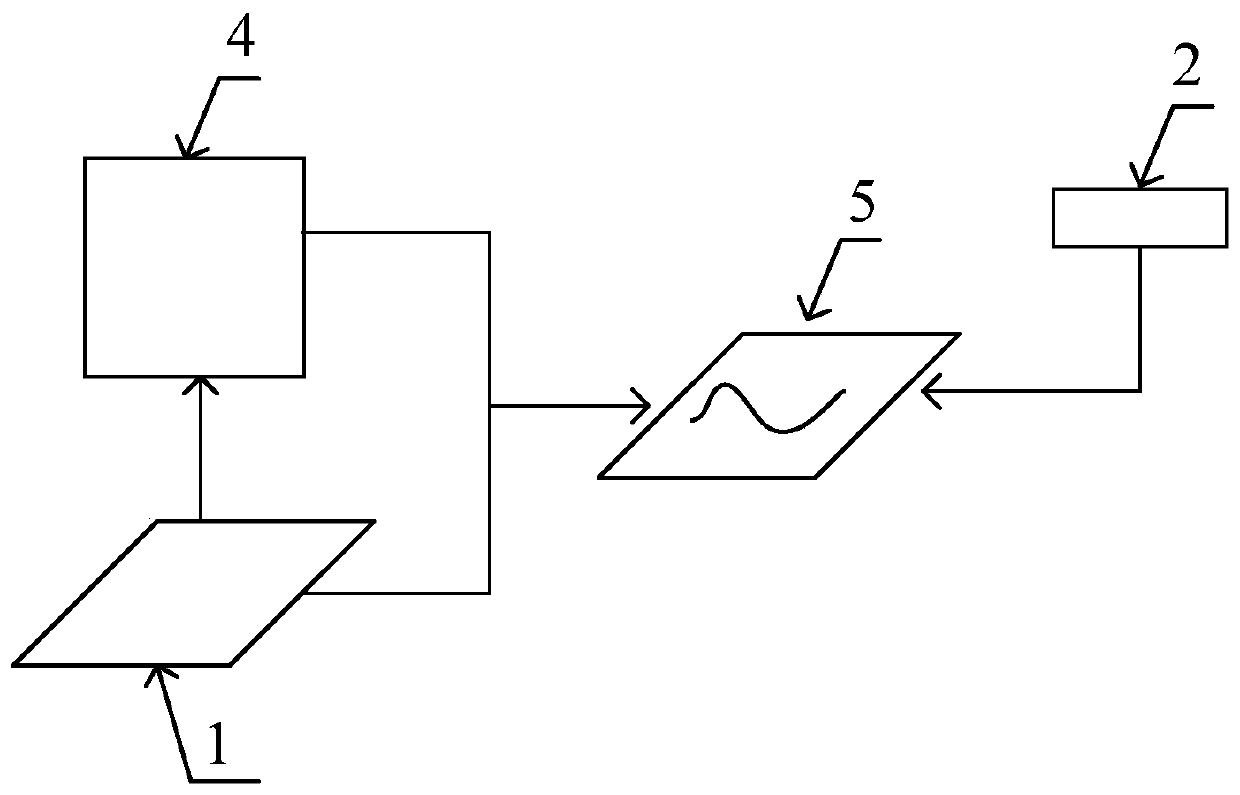

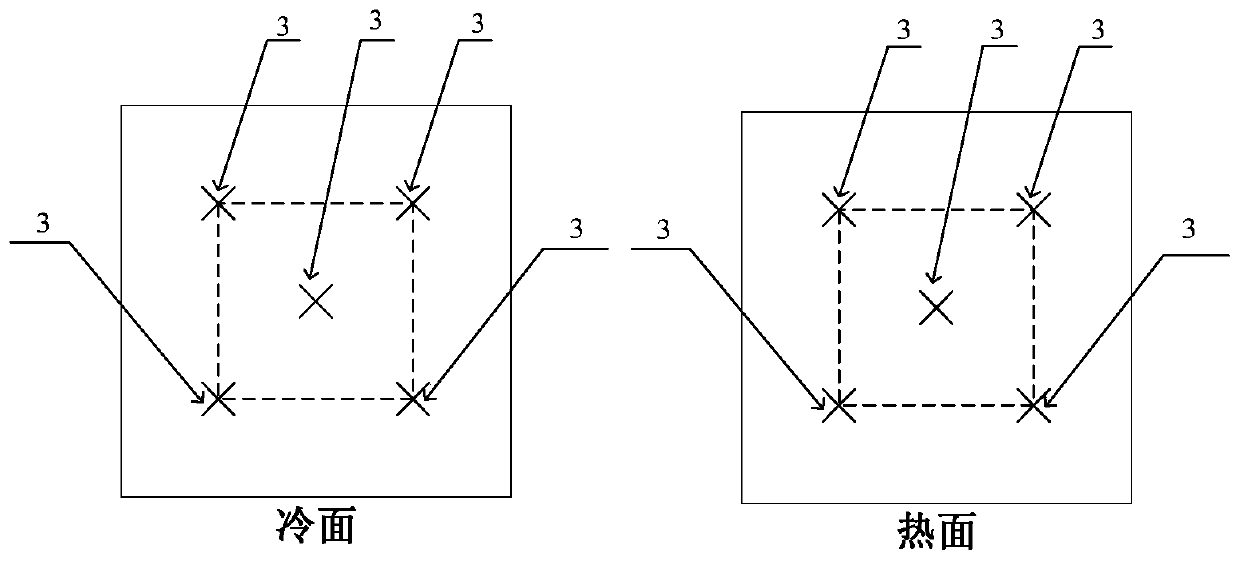

[0030] like figure 1 As shown, in this embodiment, the system for calibrating the thermal conductivity meter of the heat flow meter method based on the guarded hot plate method is realized, including the guarded hot plate method thermal conductivity meter 1, the gauge block 2, the precision thin film thermal resistance 3, the thermal conductivity standard plate 4 and the heat flow meter method Thermal conductivity meter 5.

[0031] The guarded hot plate method thermal conductivity meter includes the double specimen guarded hot plate method thermal conductivity meter or the single specimen guarded hot plate method thermal conductivity meter, all of which need to be trac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com