Device and method for preparing polyimide dielectric layer and electronic circuit on curved surface

A polyimide medium and electronic circuit technology, which is applied in the manufacturing of printed circuits, electrical components, printed circuits, etc., can solve the problems of complexity, product shape limitation, and cumbersome manufacturing process, so as to simplify the manufacturing process and facilitate the Validate the effect of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

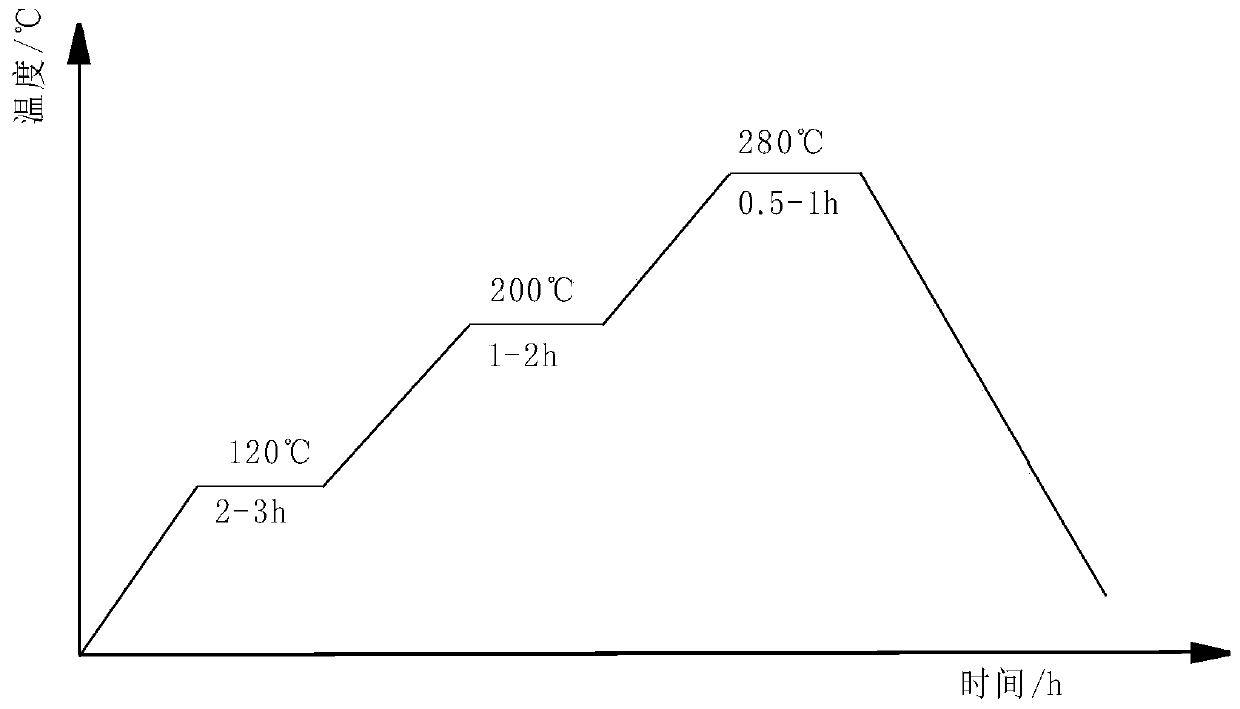

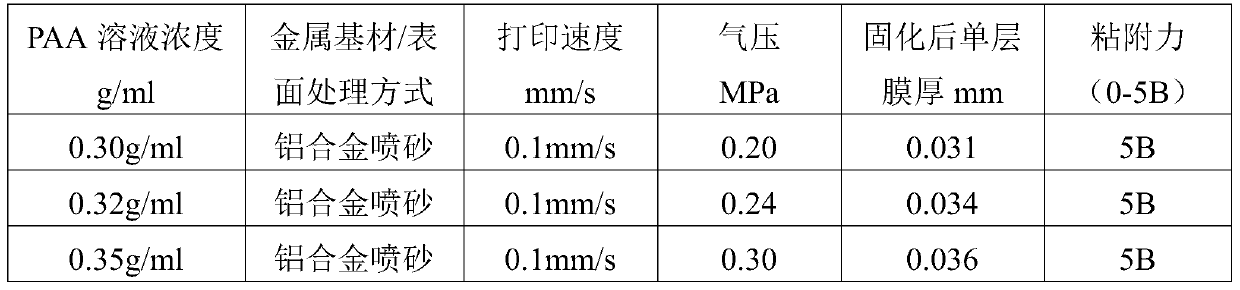

[0036] The basic principle of the present invention is to apply the printing method to coat the polyimide precursor solution PAA solution on the metal substrate, and form a PAA film, and then print the electronic circuit on the PAA film, or print the electronic circuit on the PAA film On the PI film generated by dehydration, the auxiliary heating device in the process can be formed at one time.

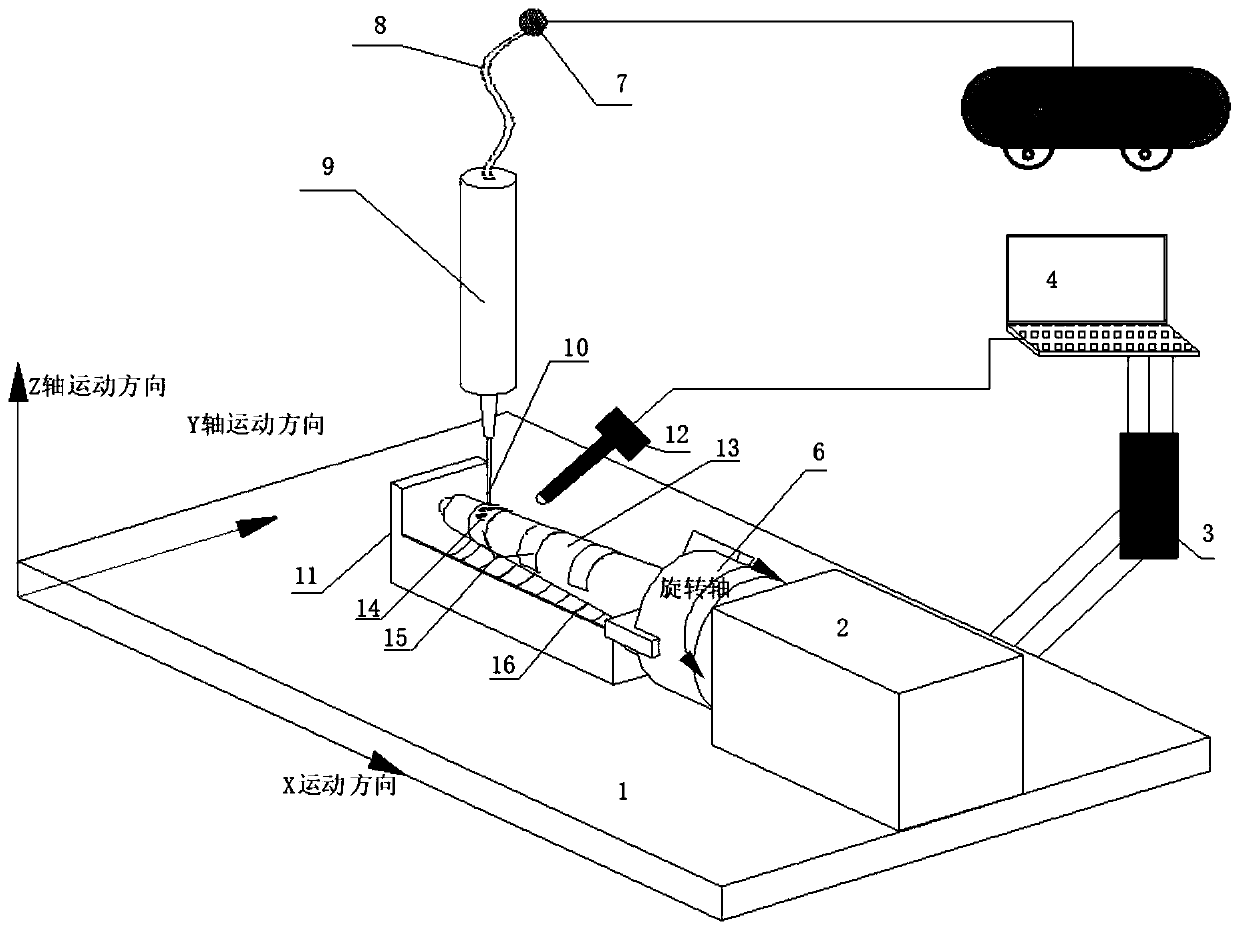

[0037] Such as figure 1 As shown, the device for preparing polyimide dielectric layer and electronic circuit on the curved surface in this embodiment includes a motion platform, a top seat, a heating device, a motor, a spray printing device, a temperature measuring device and a central controller.

[0038] The top base and the motor are installed on the motion platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com