Safe and convenient biochemical experiment device

An experimental device and biochemical technology, applied in the direction of laboratory appliances, chemical instruments and methods, supporting appliances, etc., can solve problems such as insufficient safety, inconvenient storage of chemical agents, inconvenient carrying of biochemical experimental devices, etc., to achieve Easy to fix, easy to adjust, good fixed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

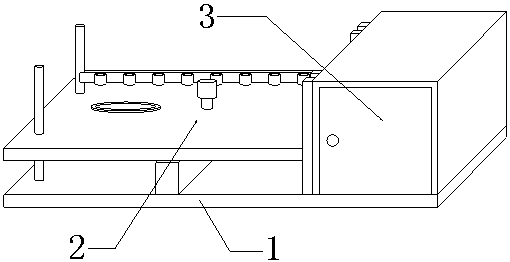

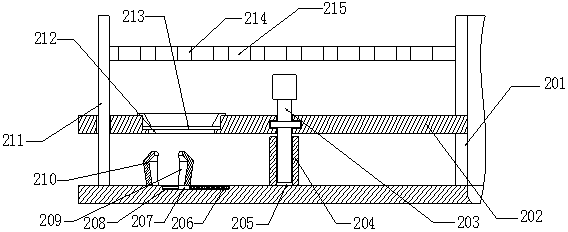

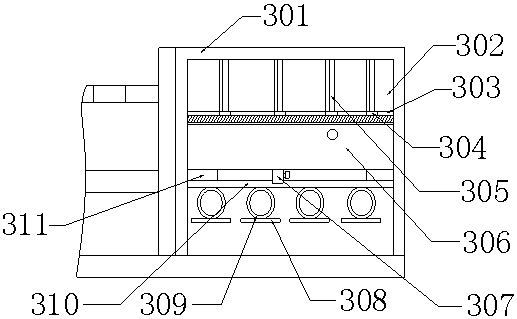

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: a safe and convenient biochemical experiment device, including a bottom plate 1, a fixing component 2 and a storage component 3, the fixing component 2 is installed on the upper end surface of the bottom plate 1, and the storage component 3 is arranged on the right side of the fixing component 2 The upper end surface of the bottom plate 1 on the side, the fixed assembly 2 includes a limit bar 201, a carrier plate 202, a screw rod 203, a fixed table 204, a threaded hole 205, a spring 206, a slider 207, a chute 208, a movable splint 209, a fixed splint 210, Guide rod 211, countersunk hole 212, asbestos net 213, carrying rod 214 and circular ring 215, storage assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com