Anti-static spraying equipment

A spraying equipment and anti-static technology, which is applied in the field of anti-static spraying equipment, can solve problems affecting the operation of devices, damage to devices, and poor anti-static effect of circuit boards, so as to avoid affecting the normal operation of devices, improve the protection effect, and facilitate The effect of taking homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

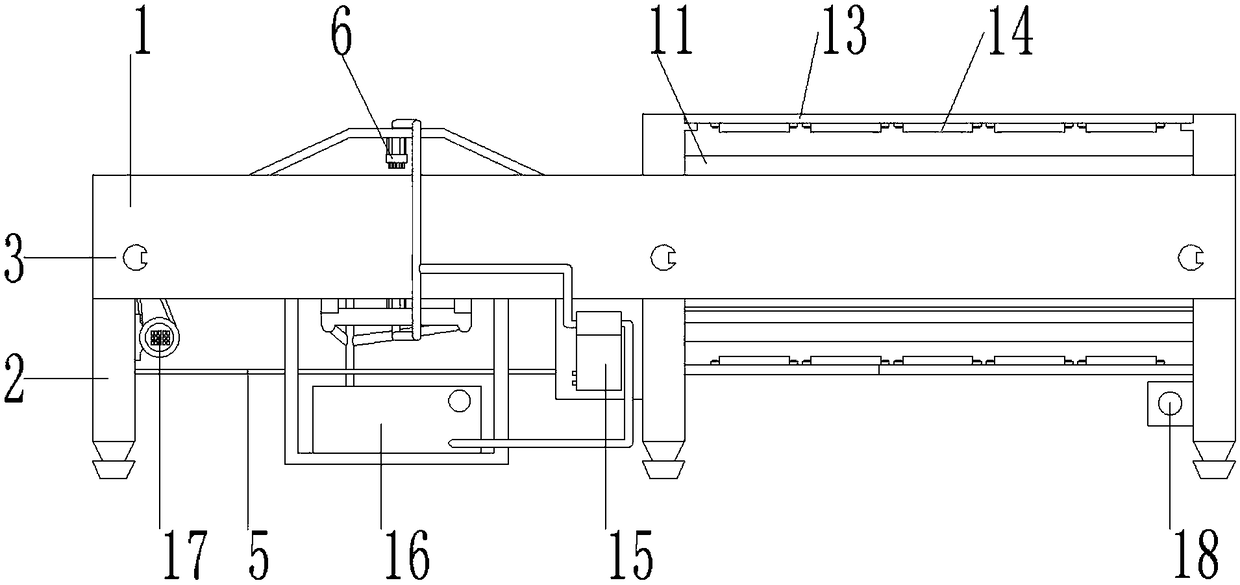

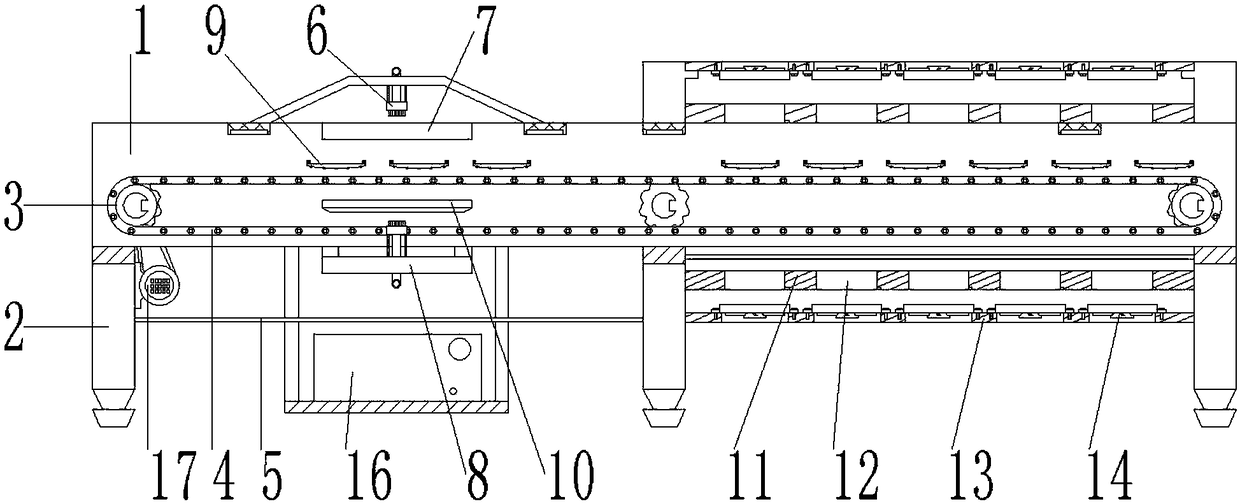

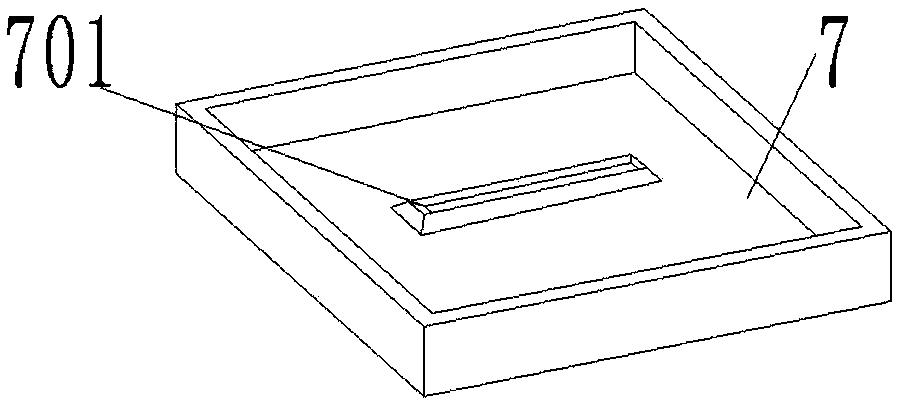

[0036] as attached figure 1 to attach Figure 11 Shown:

[0037]The invention provides circuit board anti-static spraying equipment, including a main body 1, a support column 2, a transmission wheel 3, a transmission chain 4, a nylon net 5, a fan-shaped nozzle 6, a top liquid collection tank 7, a top spray hole 701, and a bottom liquid collection tank 8 , fixed block 9, micro runner 901, liquid collecting plate 10, bottom spray hole 1001, heater attachment plate 11, heating device 12, fan attachment plate 13, exhaust fan 14, sprayer pump 15, storage box 16, motor 17, total Control switch 18, shielding plate 19, magnet 20 and liquid film 21, six support columns 2 are installed at the bottom of the main body 1, and the inside of the main body 1 is a hollow structure, and three transmission wheels 3 are transmission connected to the inner walls on both sides of the main body 1 Above, there are two transmission chains 4, and the transmission chains 4 are installed on the three t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com