Turnover trolley

A technology for flipping tables and carts, which is applied to trolleys, motor vehicles, multi-axis carts, etc. It can solve the problems of consuming physical strength of the staff, affecting the service life of the device, and poor cushioning effect of the cart, so as to achieve simple and fast flipping and reduce physical strength Consumption, convenient long-term use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

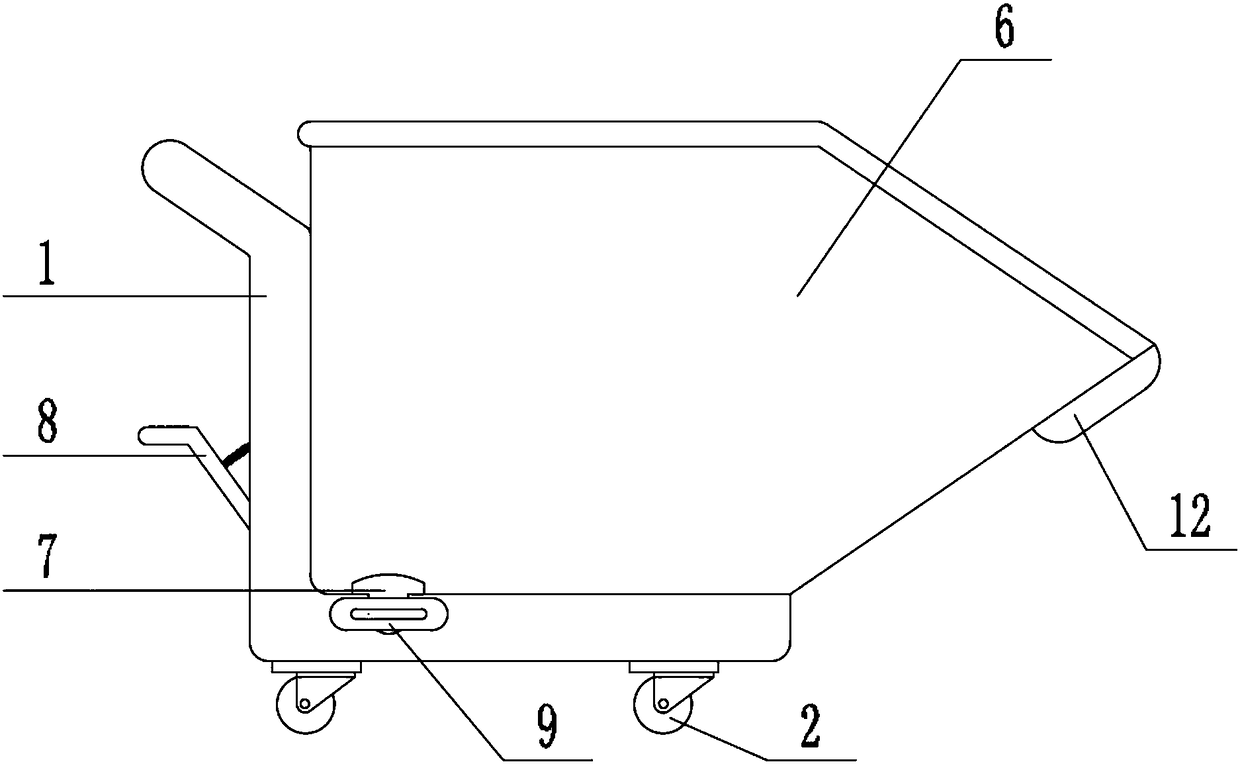

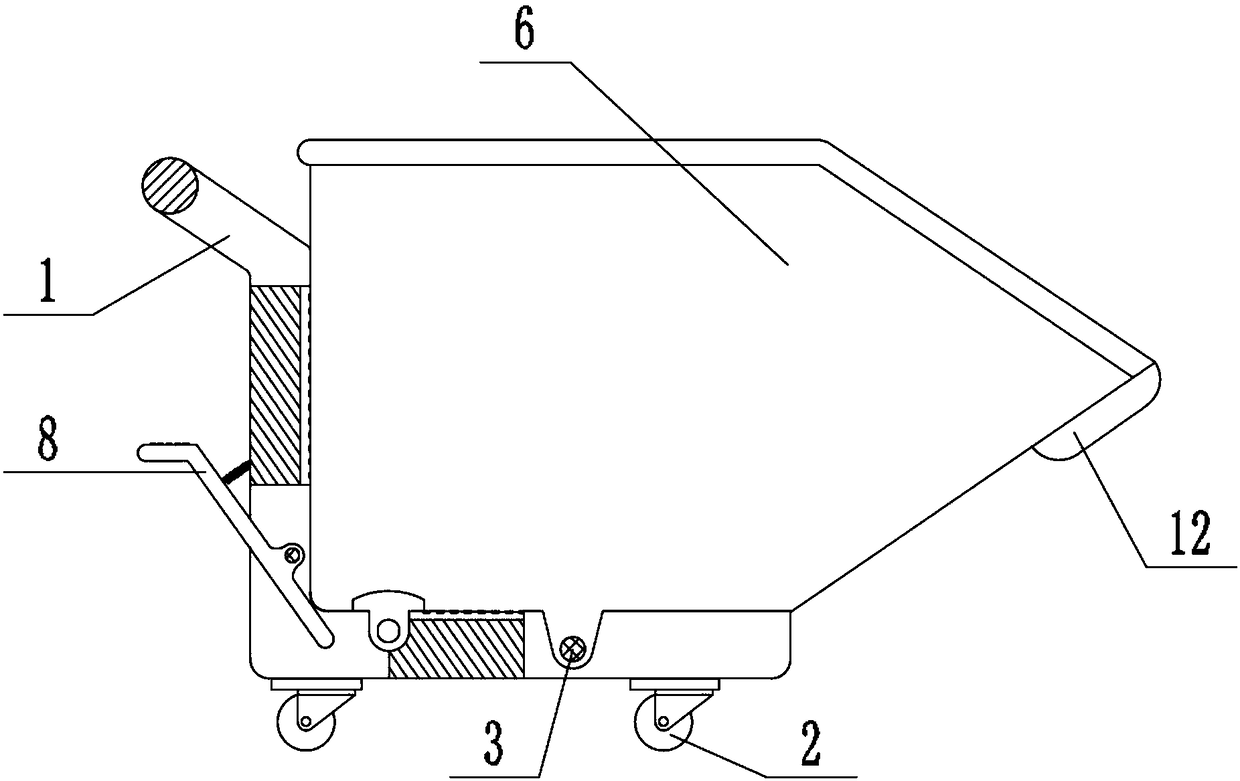

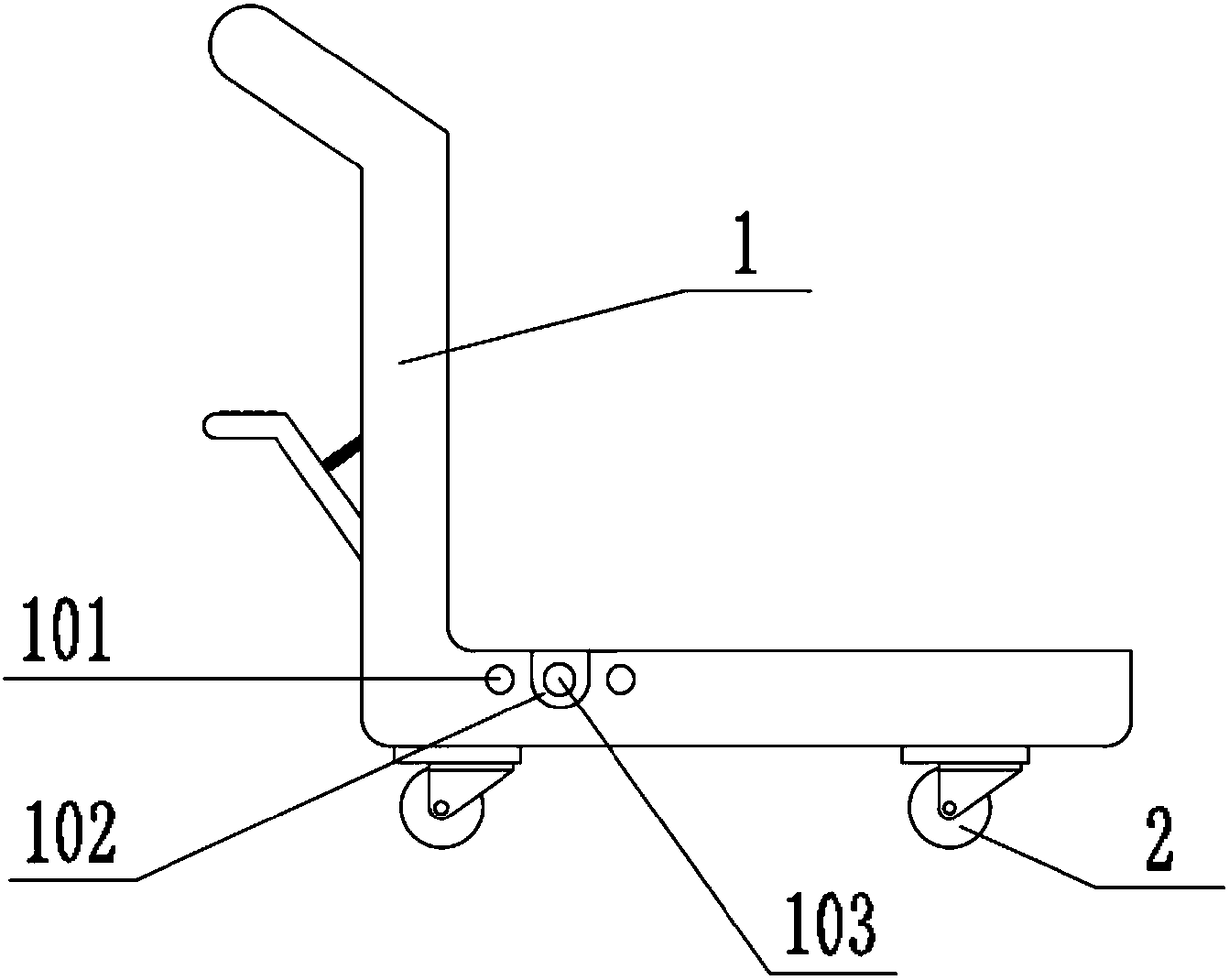

[0036] as attached figure 1 to attach Figure 9 Shown:

[0037] The present invention provides an overturning trolley, including a support frame 1, a magnet suction hole 101, a fixing hole insertion groove 102, a fixing hole 103, a universal wheel 2, a bottom rotating column 3, a left rotating column 4, a buffer pad 5, Car bucket 6, bottom rotating hole 601, fixed block 7, jack 701, seesaw 8, rotating hole 801, fixed block 9, magnet block 10, extension spring 11 and rubber buffer strip 12, described support frame 1 is L Shaped frame structure, and the front end of the support frame 1 is provided with two magnet attraction holes 101, the front end of the support frame 1 is provided with a fixed hole insertion groove 102, and a fixed hole is provided in the fixed hole insertion groove 102 103, and the fixing hole 103 communicates with the jack 701, the universal wheels 2 are four, and the four universal wheels 2 are installed on the bottom end surface of the support frame 1 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com