A shape memory epoxy foam

A technology of epoxy foam and memory, applied in the field of functional polymer materials, to achieve the effect of improving heat resistance, good pore structure, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

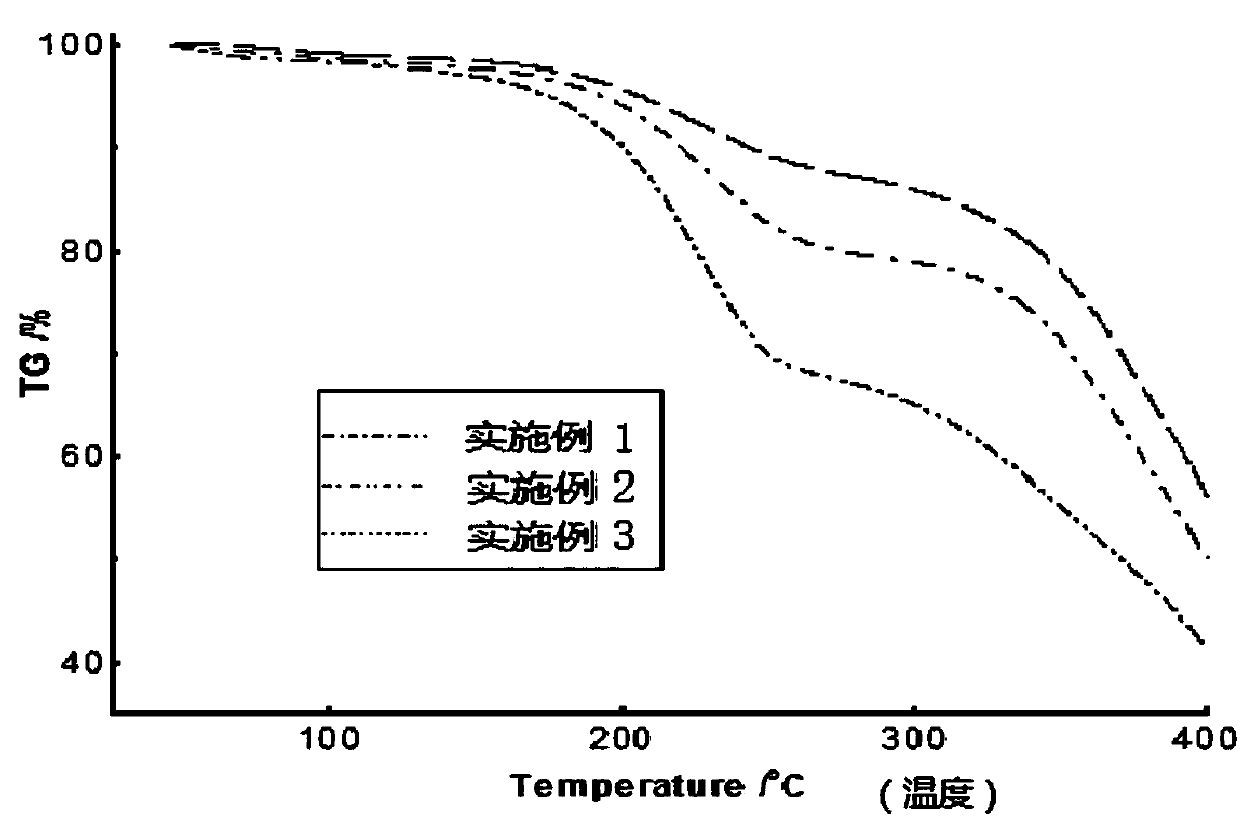

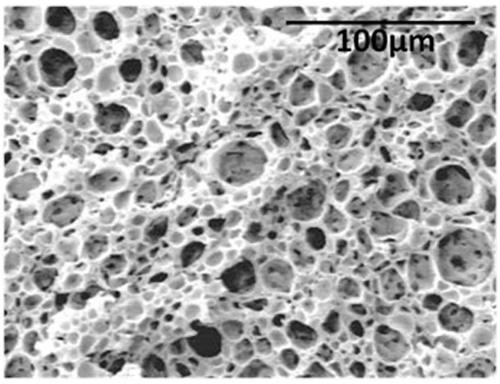

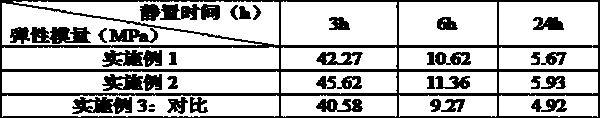

Embodiment 1

[0021] (1) Weigh 5.0g E44 type bisphenol A epoxy resin and 2.5g methyl isobutyl ketone in a round bottom flask at room temperature, heat and stir until completely dissolved. Then weigh 4.0g oligomer polyamide 650 and 2.5g methyl isobutyl ketone in a beaker, heat and stir until they are completely dissolved, pour them into a round bottom flask, mix the two and stir evenly, then add 0.75g styrene , 0.15g methyl methacrylate, 0.6g divinylbenzene, 0.01g azobisisobutyronitrile, 1.0g Span 80 and 1.0g hexadecanol were stirred until homogeneous, and placed in a 55°C water bath for pre-curing for 30min for later use.

[0022] (2) Add 0.17g of calcium chloride to 25ml of deionized water, mix well and set aside.

[0023] (3) Add step (2) dropwise to step (1) under mechanical stirring, and control the dropping time for about 8-10 minutes to obtain a milky white emulsion stable system, which is moved to a reaction kettle and placed in a 50 Continue to react in a water bath at ~60°C for 8...

Embodiment 2

[0025] (1) Weigh 5.0g E51 type bisphenol A epoxy resin and 2.8g methyl isobutyl ketone in a round bottom flask at room temperature, heat and stir until completely dissolved. Then weigh 4.5g oligomer polyamide 650 and 3.0g methyl isobutyl ketone in a beaker, heat and stir until they are completely dissolved, pour them into a round bottom flask, mix the two and stir evenly, then add 0.8g styrene , 0.2g methyl methacrylate, 0.5g divinylbenzene, 0.01g azobisisobutyronitrile, 1.5g Span 80 and 2.0g hexadecanol were stirred until homogeneous, and placed in a 55°C water bath for 30min pre-curing for later use.

[0026] (2) Add 0.07g of calcium chloride to 10ml of deionized water, mix well and set aside.

[0027] (3) Under mechanical stirring, use a dropper to add step (2) to step (1), and control the dropping time for about 8-10 minutes to obtain a milky white emulsion stable system, which is moved to the reaction kettle and placed in Continue to react in a water bath at 50-60°C for...

Embodiment 3

[0028] Embodiment 3: comparative example

[0029] (1) Weigh 5.0g E44 type bisphenol A epoxy resin and 2.5g methyl isobutyl ketone in a round bottom flask at room temperature, heat and stir until completely dissolved. Then weigh 4.0g oligomer polyamide 650 and 2.5g methyl isobutyl ketone in a beaker, heat and stir until they are completely dissolved, pour them into a round bottom flask, mix the two and stir evenly, then add 1.0g Span 80. Stir 1.0 g of cetyl alcohol until uniform, place in a water bath at 55°C for 30 minutes for pre-curing and set aside.

[0030] (2) Add 0.17g of calcium chloride to 25ml of deionized water, mix well and set aside.

[0031] (3) Add step (2) dropwise to step (1) under mechanical stirring, and control the dropping time for about 8-10 minutes to obtain a milky white emulsion stable system, which is moved to a reaction kettle and placed in a 50 Continue to react in a water bath at ~60°C for 8~10 hours until the curing reaction is complete, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com