A pressure bearing detection device

A detection device and pressure bearing technology, applied in the direction of mechanical depth measurement, etc., can solve the problem that bearing detection cannot be carried out continuously, and achieve the effect of saving detection process, high degree of automation, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

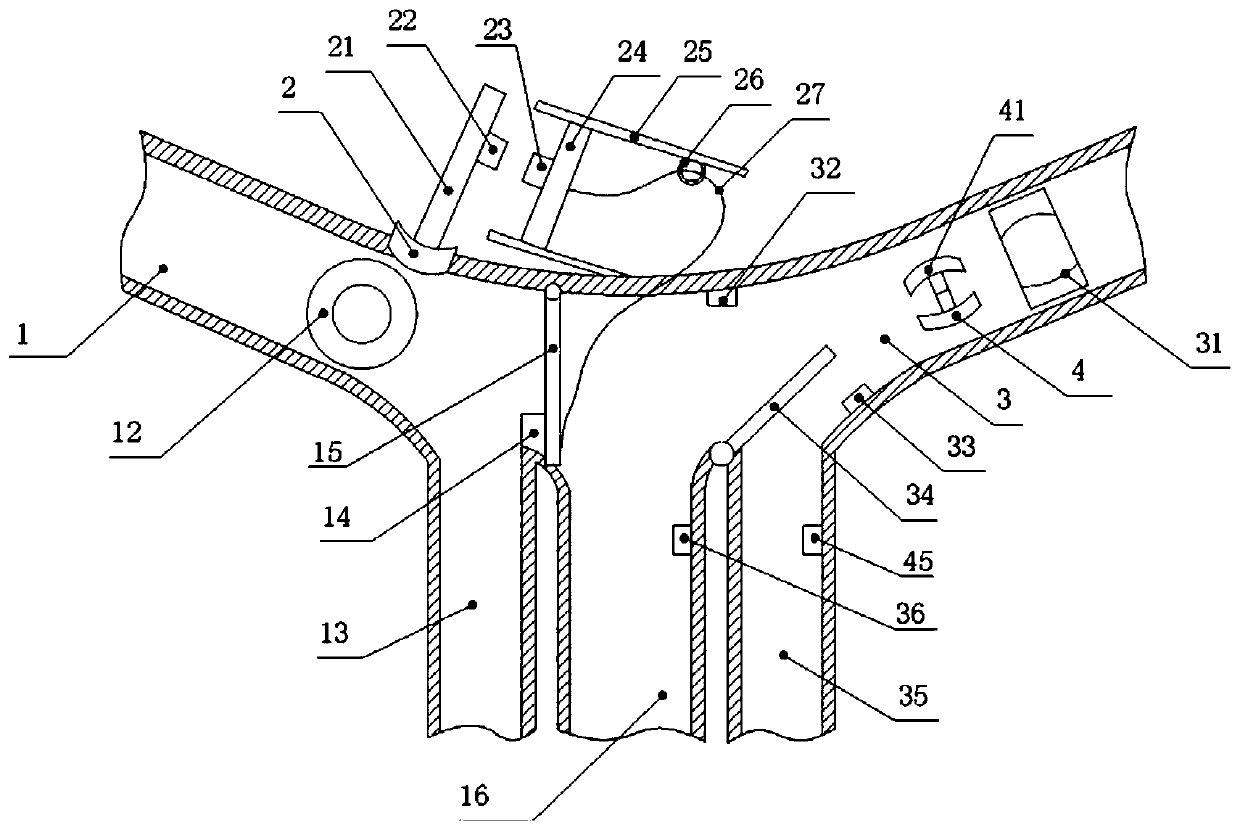

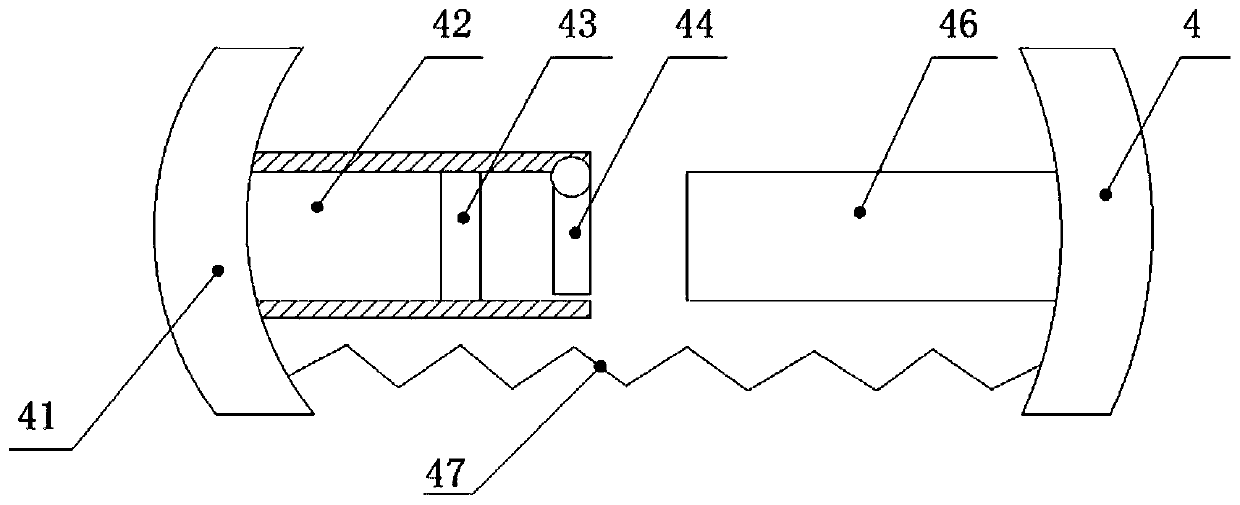

[0025] The reference signs in the drawings of the specification include: inner ring detection channel 1, guide shaft 11, inner ring 12, first recovery channel 13, stopper 14, first valve plate 15, discharge channel 16, detection block 2, second A rod 21, a first magnet 22, a second magnet 23, a second pole 24, a slide rail 25, a collar 26, a rope 27, an outer ring detection channel 3, an outer ring 31, a first electromagnet 32, a second Electromagnet 33, second valve plate 34, second recovery channel 35, third switch 36, first slider 4, second slider 41, sleeve 42, second switch 43, first switch 44, fourth switch 45, push rod 46, spring 47.

[0026] Such as figure 1 As shown, a pressure bearing detection device of the present invention includes a first recovery channel 13, an inner ring detection channel 1 is communicated with the upper left side of the first recovery channel 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com