Vibrating wire sensor installation tool and vibrating wire sensor installation method

A vibrating wire sensor and installation tool technology, which is applied in the measurement, instrument, measuring device and other directions by measuring the frequency change force of the stressed vibration element, can solve the problems of limited accuracy, time-consuming and labor-consuming, time-consuming, etc. Achieve the effect of improving adjustment speed and accuracy, saving time and reducing operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

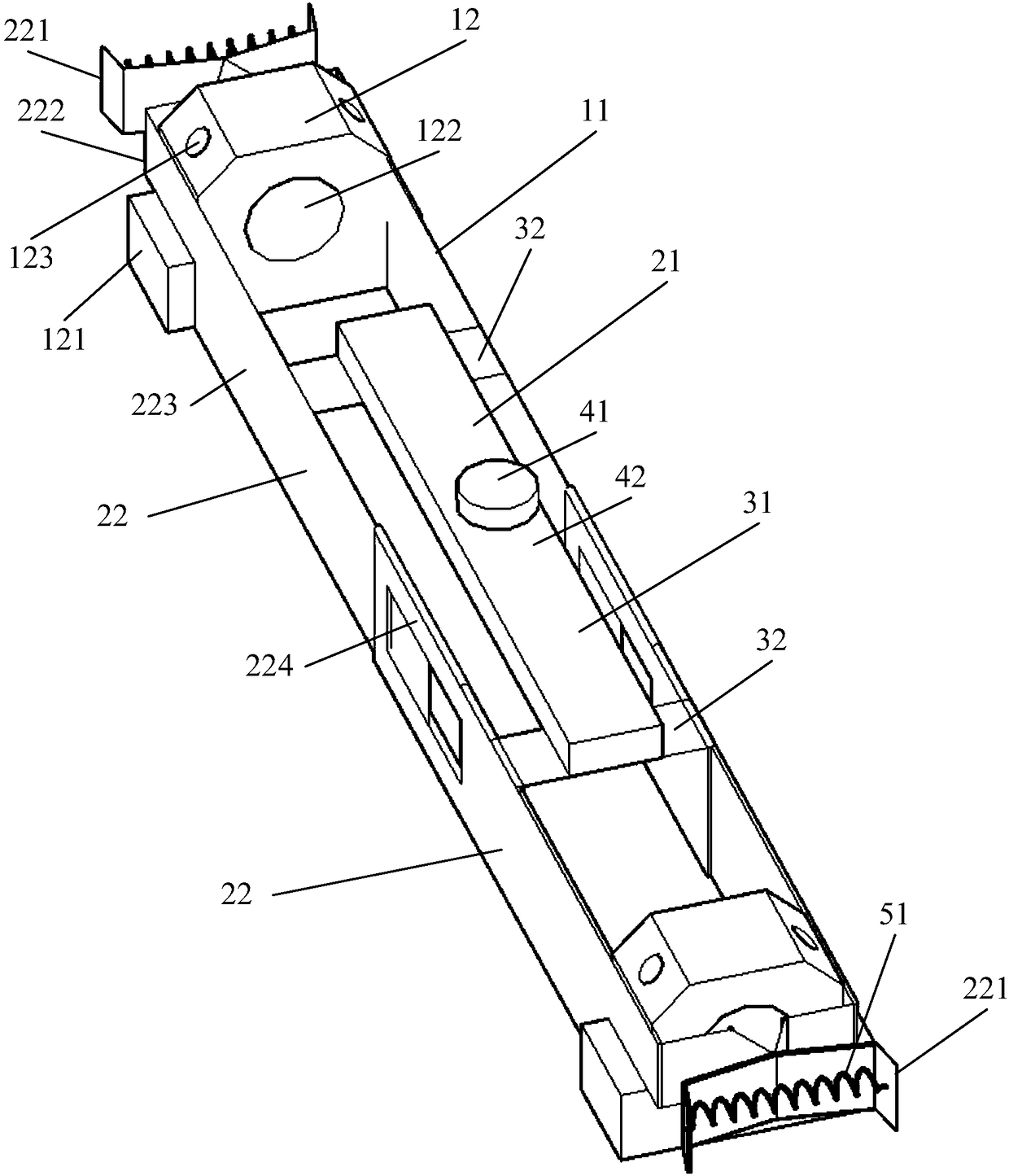

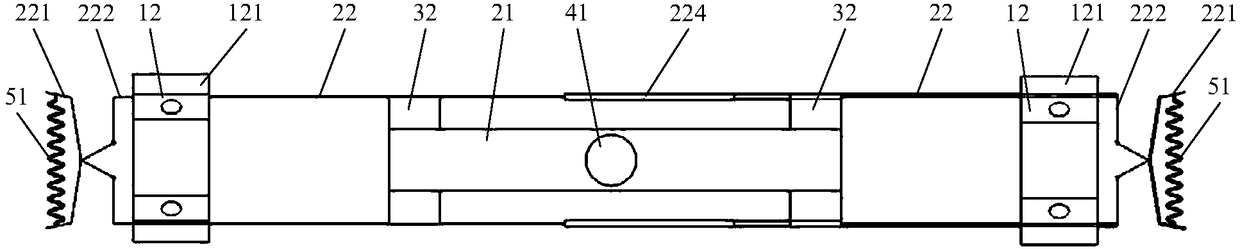

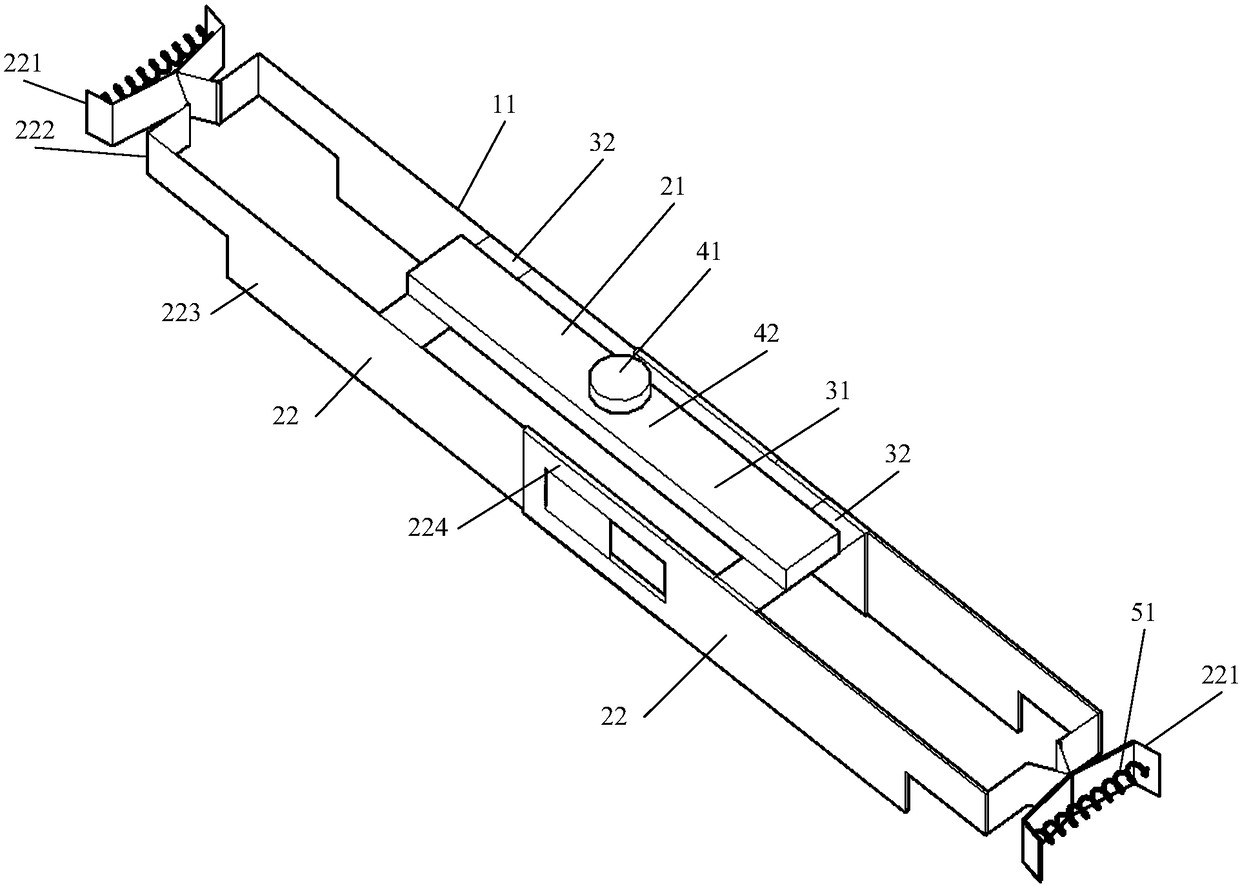

[0054] figure 1 It is a three-dimensional schematic diagram of the installation tool of the vibrating wire sensor in the embodiment of the present invention, figure 2 It is a top view of the installation tool of the vibrating wire sensor in the embodiment of the present invention, image 3 It is a three-dimensional schematic diagram of the installation tool of the vibrating wire sensor after removing the spacer in the embodiment of the present invention, Figure 4 It is a three-dimensional schematic diagram of an installation tool equipped with a vibrating wire sensor in an embodiment of the present invention, Figure 5 It is a schematic diagram of the installation of the vibrating wire sensor and the pad in the embodiment of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap