Infrared spinning yarn breakage detecting device

A wire breakage detection and infrared technology, applied in the direction of optical device exploration, etc., can solve the problems of lack of wire breakage detection and monitoring devices, increase the labor intensity of spinning workers, affect yarn quality, etc., and achieve low power consumption, simple structure, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

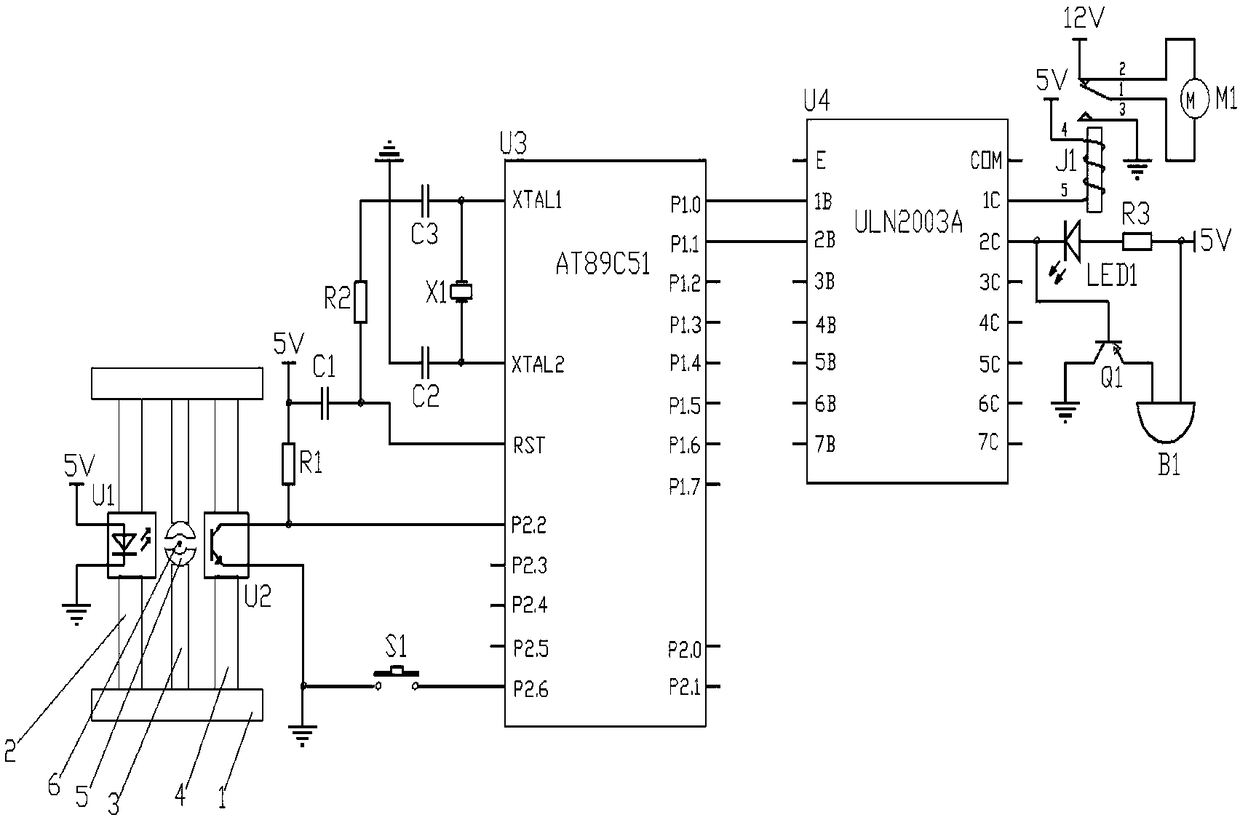

[0014] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, an infrared spinning thread break detection device includes a detection bracket 1 fixedly installed on the yarn machine, one end of the detection bracket 1 is provided with a first mount 2, and an infrared light emitter is installed on the first mount 2 U1, the other end of the detection bracket 1 is provided with a second mounting base 4, an infrared light receiver U2 is installed on the second mounting base 4, a third mounting base 3 is provided in the middle of the detection bracket 1, and a third mounting base 3 is provided on the third mounting base 3 There is a thread passing groove 5, and two gaps are arranged on the thread passing groove 5, one of which is close to the emission hole of the infrared light transmitter U1, and the other gap is close to the receiving hole of the infrared light ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap