A Carbide Reinforced Low Expansion Alloy

A low-expansion alloy and carbide technology, applied in the field of carbide-reinforced low-expansion materials, can solve the problems of low strength, high expansion coefficient, and poor alloy plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The alloy is prepared as follows:

[0030] a. Melting: use vacuum induction furnace to smelt alloy, vacuum degree ≤1×10 -1 Pa, during the smelting process, the burning loss of alloy elements should be strictly controlled, so that the composition of the alloy can be controlled within the design range. Among them, Fe and Ni are directly put into the crucible as a primary feed; V, Ti, Nb, C, Si, and Mn are put into the hopper of a vacuum induction furnace as a secondary feed. The vacuum chamber of the induction furnace casts molten steel into ingots;

[0031] b. Hot forging: After the steel ingot is peeled off, it is lower than 700°C and loaded into a furnace. The heating rate of the alloy ingot is controlled at 100-200°C per hour, and after a proper time of heat preservation at 1150±10°C, the billet is forged to the required specifications;

[0032] c. Heat treatment: hot forging alloy, after solution quenching at 1050±50°C, vacuum aging treatment at 500-600°C for 2-4 ...

Embodiment

[0034] The five-component alloys in Table 1 were smelted using the processing technology of vacuum induction melting→1100°C forging forming→1050°C×30min water quenching→560°C holding for 3h tempering treatment.

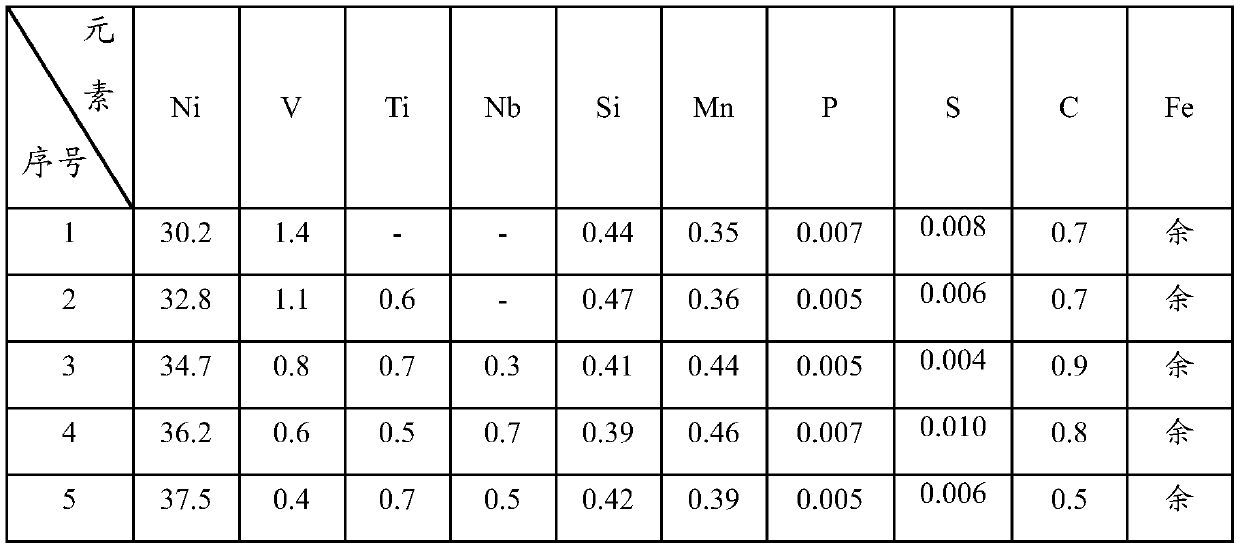

[0035] Chemical composition (mass percent %) of table 1 smelting alloy

[0036]

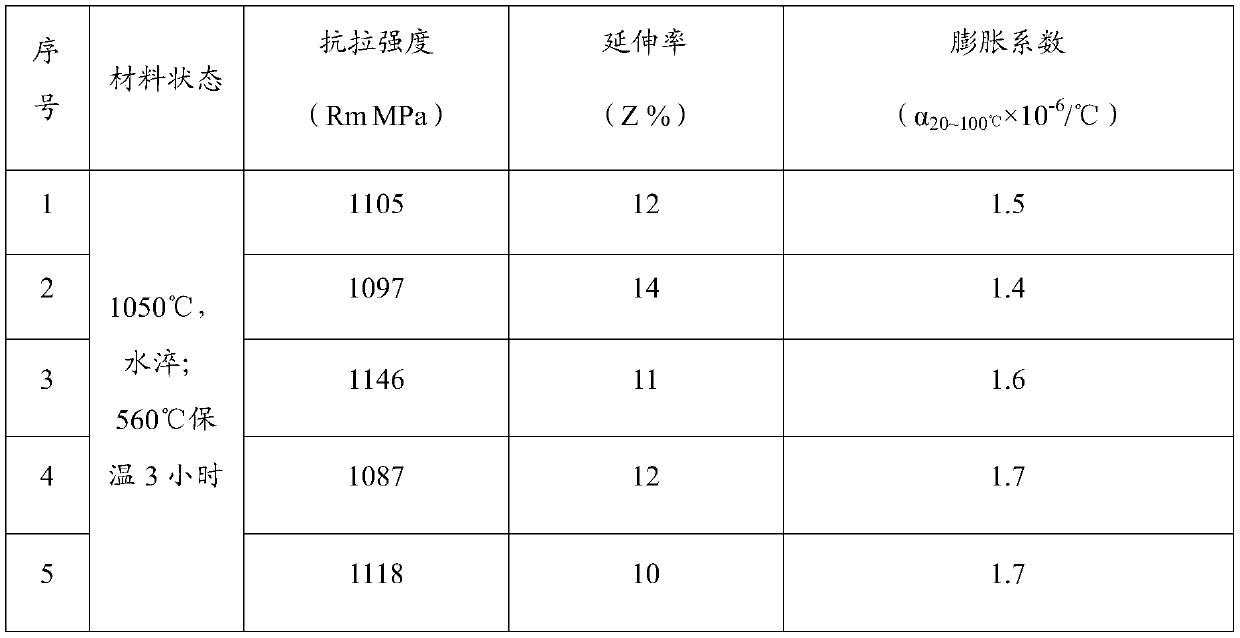

[0037] The physical and mechanical properties of the carbide-strengthened low-expansion alloy prepared by the above process are shown in Table 2.

[0038] The room temperature tensile strength Rm of the carbide-reinforced low-expansion alloy is greater than 1000MPa, the elongation at break Z is greater than 5%, and the expansion coefficient α 20~100℃ -6 / °C.

[0039] Table 2 Physical and mechanical properties of carbide-reinforced low-expansion alloys

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com