Novel concave disk for agriculture

A technology of concave surface and disc, which is applied in the field of agricultural equipment, can solve the problems of discs such as large resistance to turning over soil, easy to break, and poor ability to break soil, and achieve the effect of reducing resistance to turning over soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

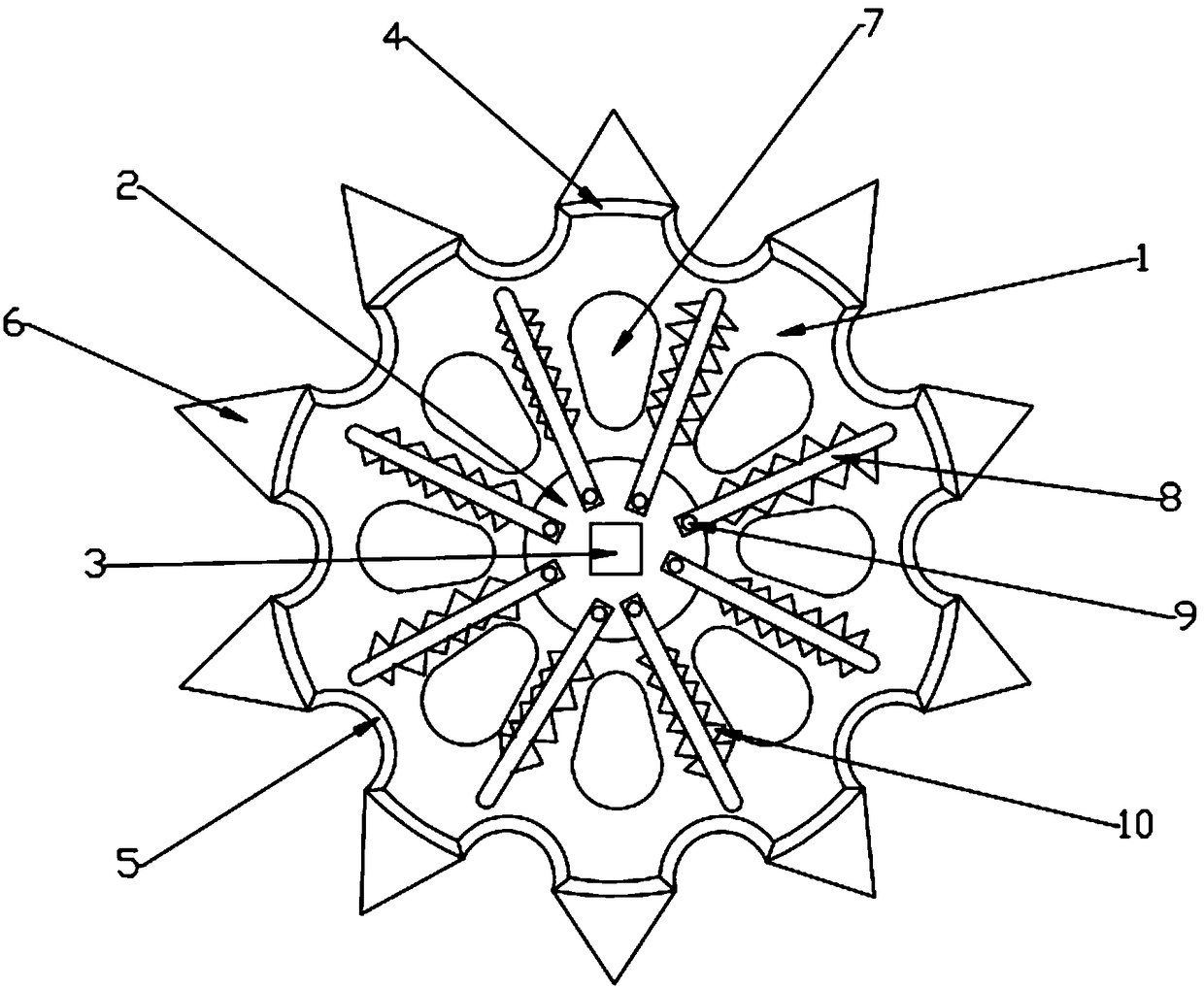

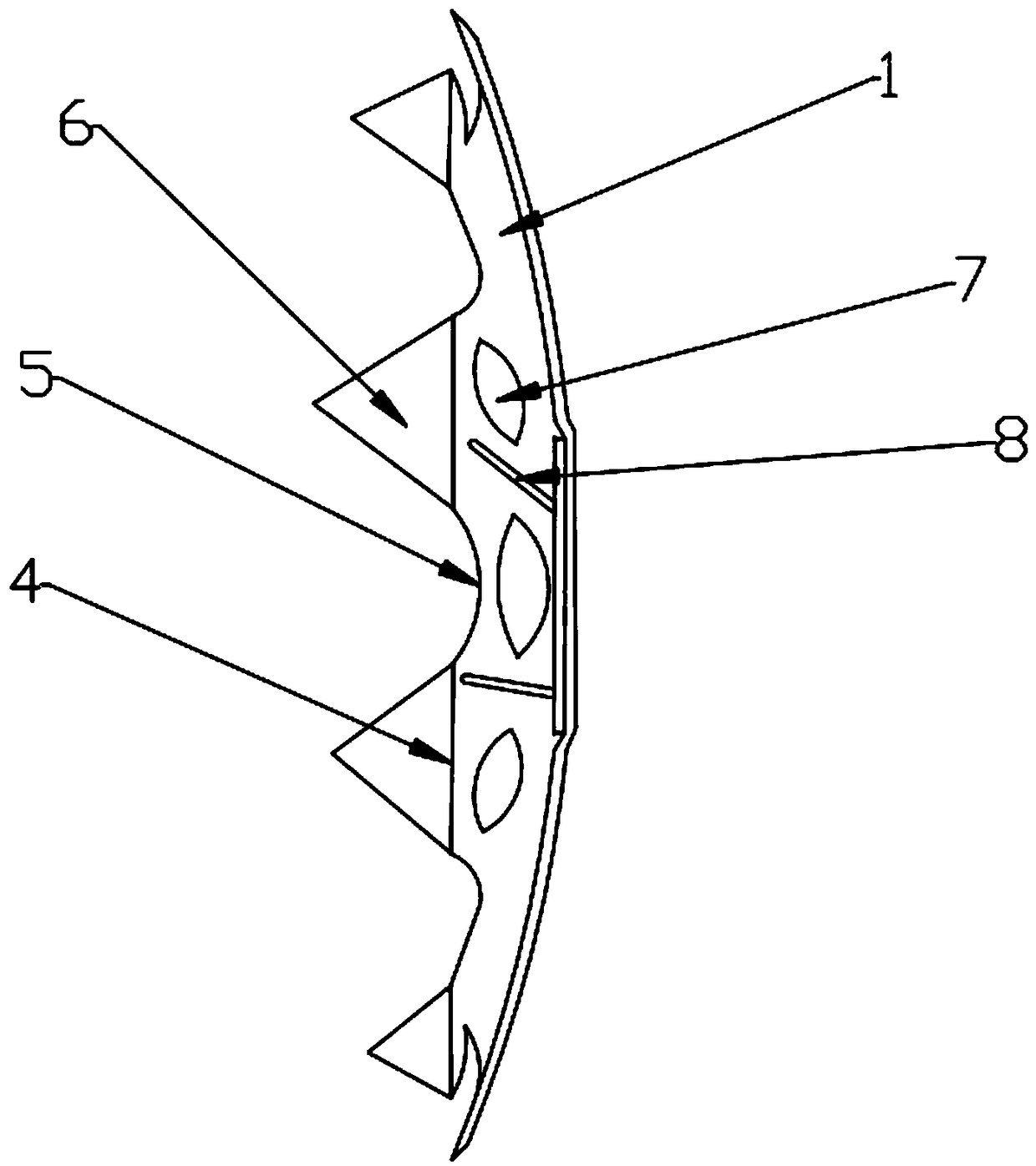

[0015] A new type of concave agricultural disk, comprising a circular cutter head 1, the circular cutter head 1 is concave with a certain radian, the center of the circular cutter head 1 is provided with a mounting piece 2, the The center of the mounting piece 2 is provided with a stamped mounting hole 3, and the outer peripheral edge of the circular cutter head 1 is provided with a number of integrally formed disc blades 4, and the outer peripheral edge of the circular cutter head 1 is An integrally formed arc-shaped notch 5 is provided between two adjacent disc blades 4, and a pointed corner 6 is provided on the circular cutter head 1 at the back side of the disc blades 4, and the pointed corner 6 is triangular in shape, and the concave surface of the circular cutter head 1 is provided with hollow holes 7 surrounding a circle, and the mounting piece 2 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com